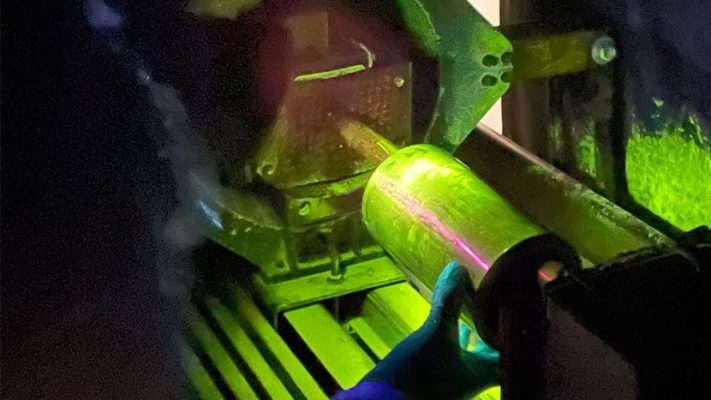

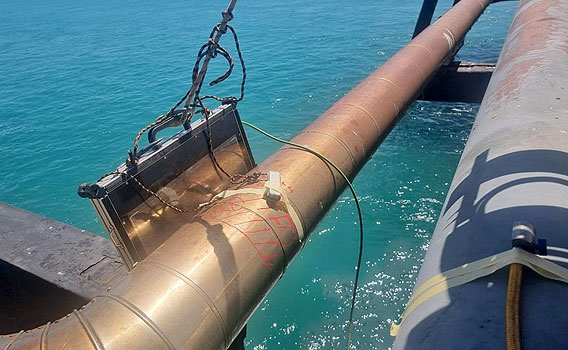

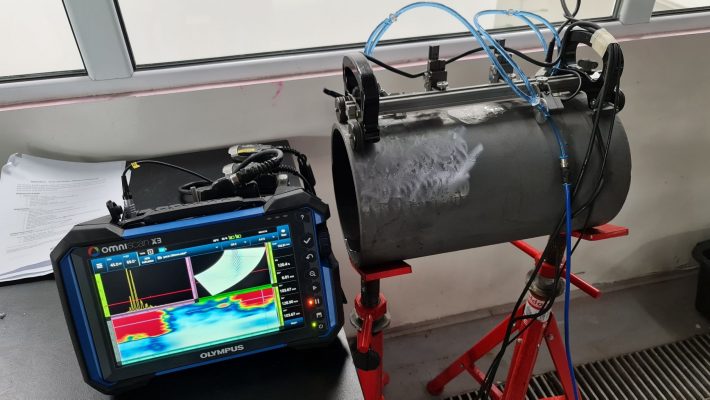

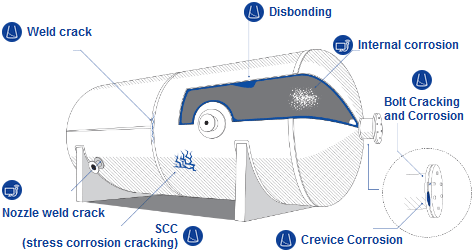

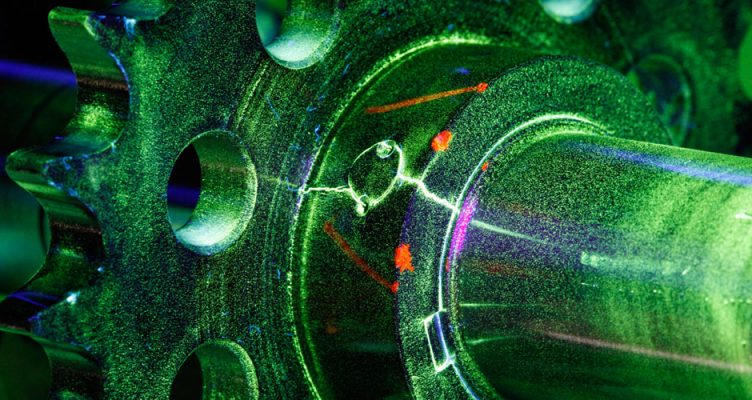

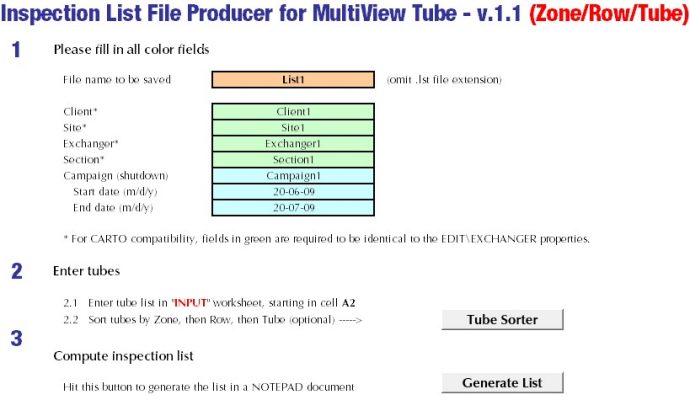

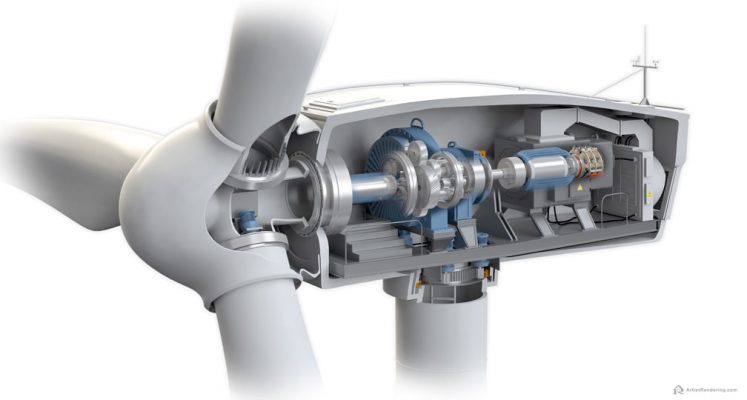

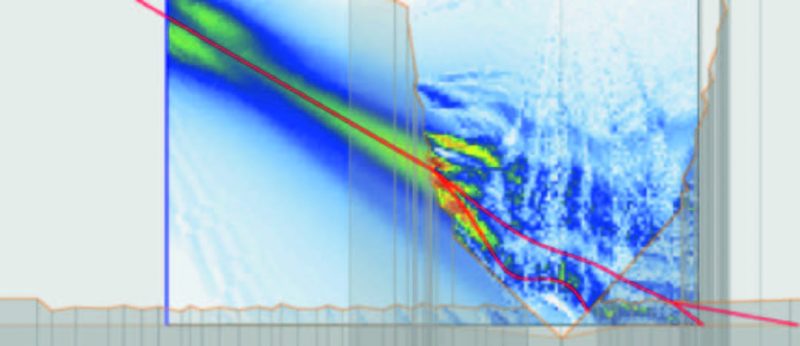

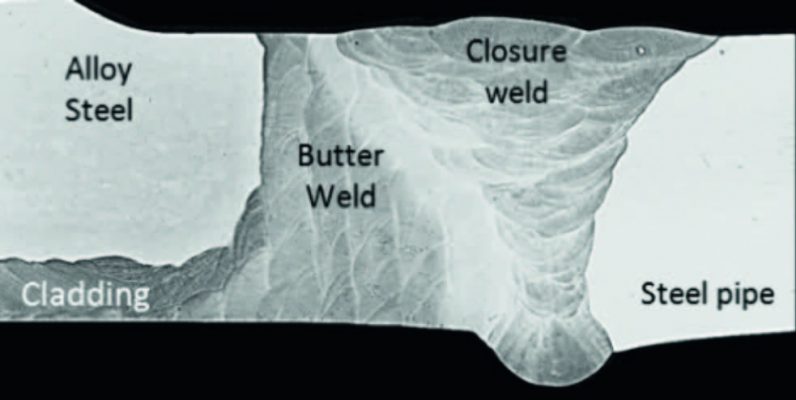

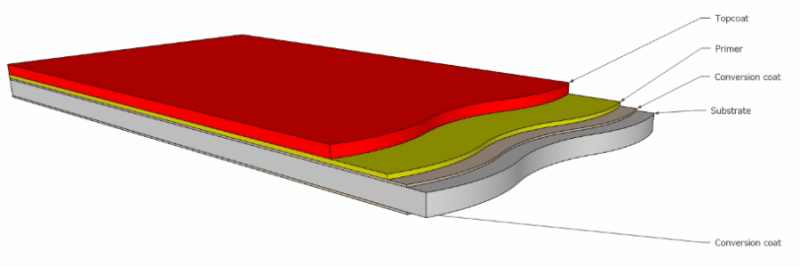

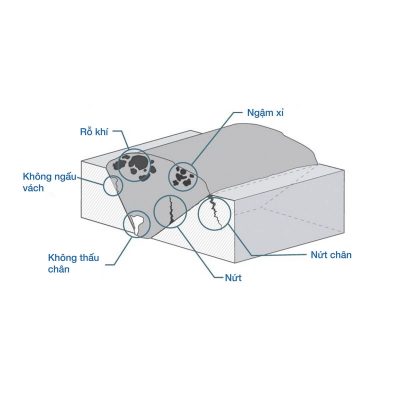

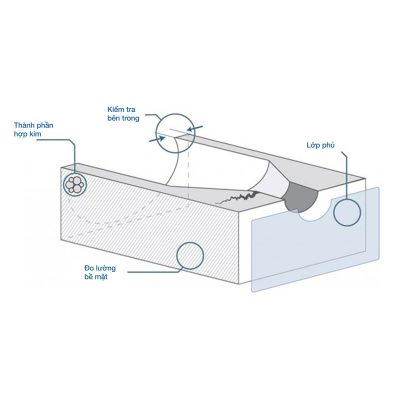

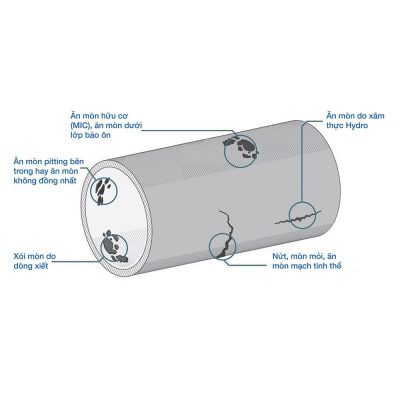

Phương pháp tiếp cận khi đánh giá ăn mòn dưới lớp cách nhiệt (CUI) của hệ thống đường ống

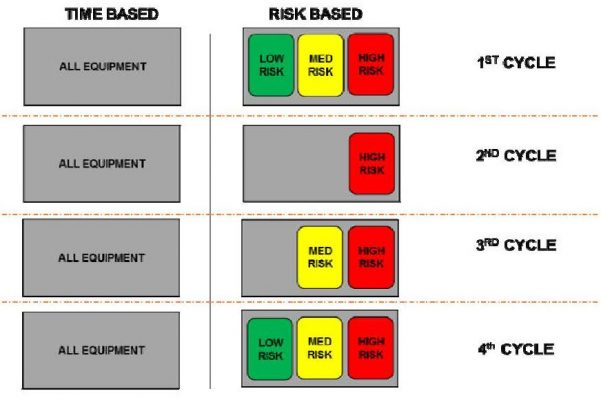

Tham khảo thêm: Kiểm tra ăn mòn dưới lớp bảo ôn Một phương pháp tiếp cận từng bước trong quá trình kiểm tra CUI đảm bảo không bỏ sót các khu vực cần kiểm tra. Kế hoạch chi tiết và hướng tiếp cận đúng sẽ tiết kiệm cả tiền bạc...

Quan tâm nhiều

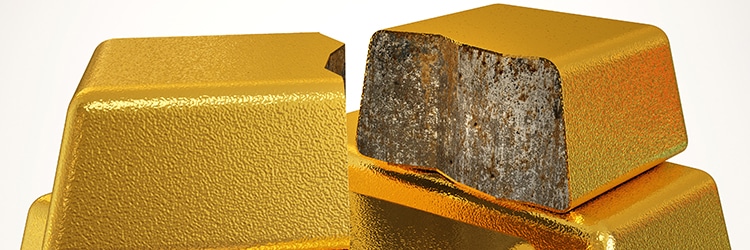

Những viên kim cương thô đôi khi có thể bị nhầm với những viên sỏi vô giá trị, trừ khi bạn có máy XRF

Bạn có bao giờ thắc mắc liệu chiếc nhẫn gia truyền có chứa kim cương thật hay chỉ là đá giả kim cương không? XRF có thể giúp giải đáp bí ẩn này! Cách phát hiện đá quý giả: Dấu hiệu nhận biết và chiến lược thông minh Có vẻ...

Ngọc trai nước mặn hay nước ngọt? Sử dụng XRF giúp bạn phân biệt nguồn gốc ngọc trai

Những viên ngọc trai đẹp, sáng bóng luôn là phụ kiện được ưa thích trong ngành trang sức. Tuy nhiên, giá trị của các mẫu sinh học này từ môi trường tự nhiên thay đổi rất nhiều tùy thuộc vào loại ngọc trai và các đặc điểm như kích thước,...

VISCO introduces the ND-E expert system chatbot

Tuy nhiên, với sự phát triển của trí tuệ nhân tạo (AI), giờ đây chúng ta đang chứng kiến sự xuất hiện của một chuyên gia mới: AI ND-E đến từ VISCO. Nếu các bạn có xem qua bộ phim Wall-E thì tên của Chatbot AI của VISCO lấy cảm...

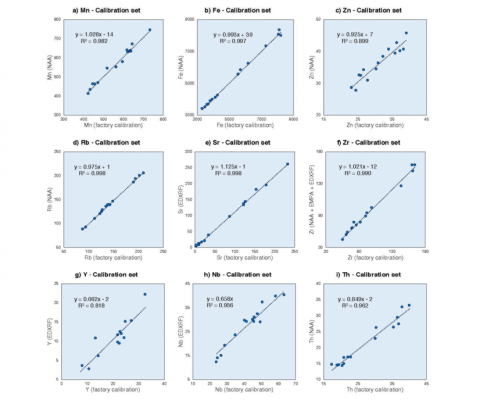

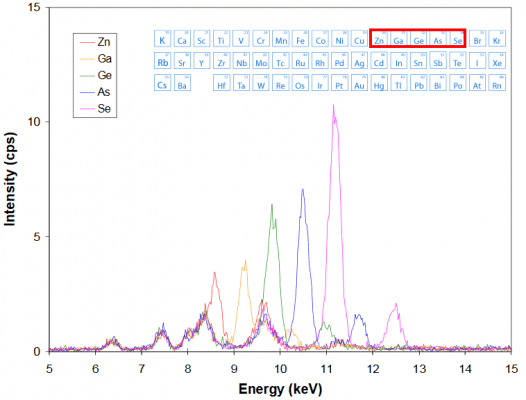

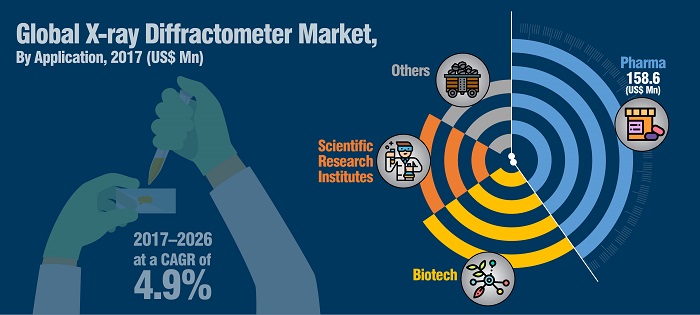

Phân tích kim loại hòa tan với Evident Vanta XRF

Giới thiệu Quy trình phân tích kim loại hòa tan trong nước bao gồm lấy mẫu, sau đó phân tích bằng các thiết bị trong phòng thí nghiệm như ICP-MS, ICP-OES hoặc AAS. Sự chậm trễ vốn có từ khi lấy mẫu đến khi nhận được kết quả có thể...

Máy phân tích Vanta XRF kiểm tra chì trong nước uống

Đạo luật Nước uống an toàn liên bang Hoa Kỳ (SDWA) đã được sửa đổi vào năm 2011 để giảm mức chì (Pb) được chấp nhận xuống 0,25% trong đường ống, phụ kiện ống, chất hàn và chất trợ dung tiếp xúc với nước uống. Có hiệu lực vào tháng...

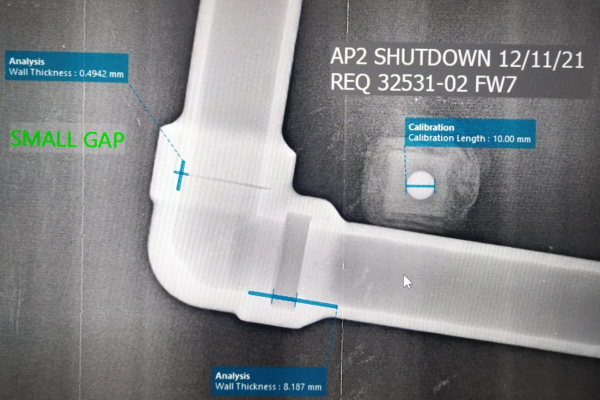

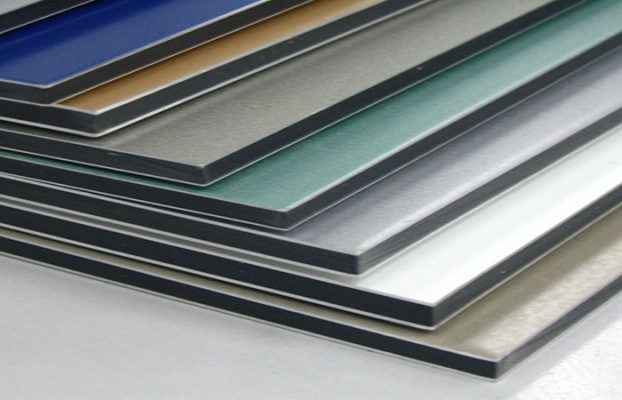

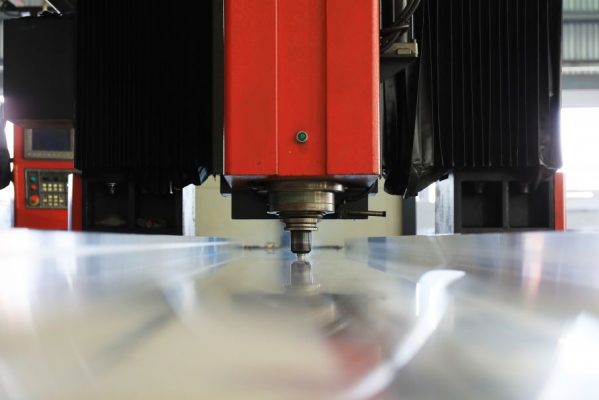

Đo độ dày của sản phẩm thủy tinh và lớp phủ thủy tinh

Ghi chú ứng dụng này giải thích cách đo độ dày thành của các sản phẩm thủy tinh, chẳng hạn như chai, hộp đựng, ống, tấm và đĩa, đồ thủy tinh khoa học, bóng đèn cũng như độ dày của lớp phủ thủy tinh trên các hộp đựng có lót...

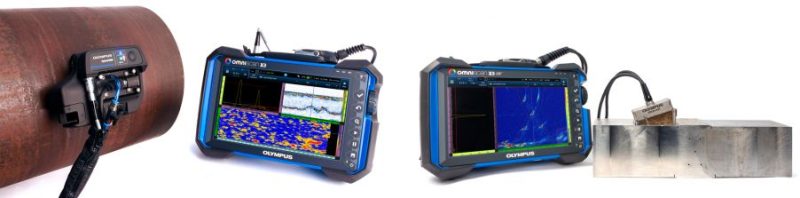

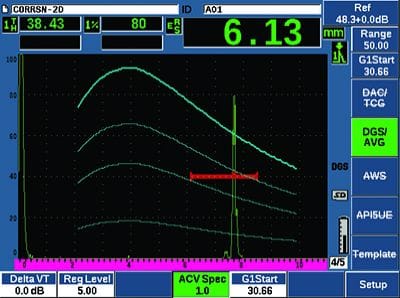

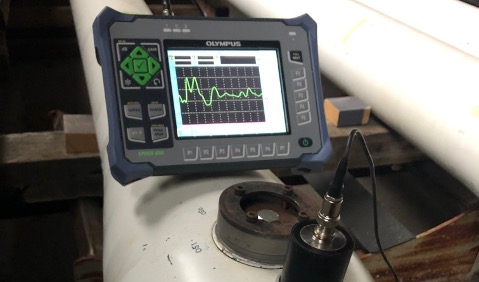

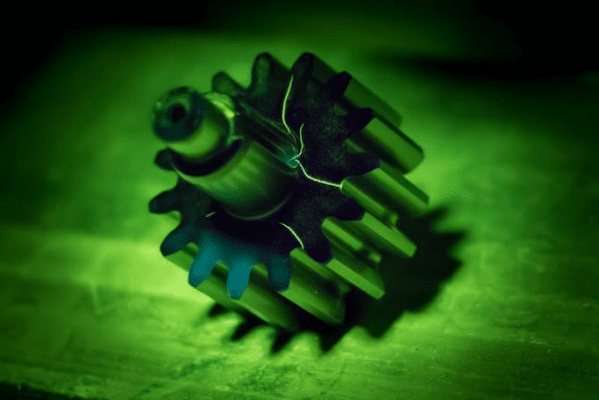

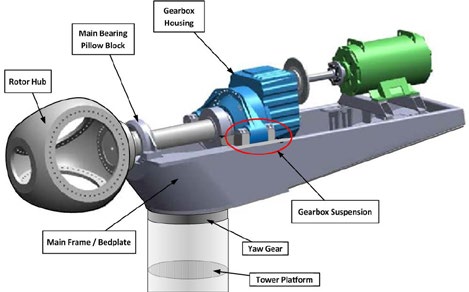

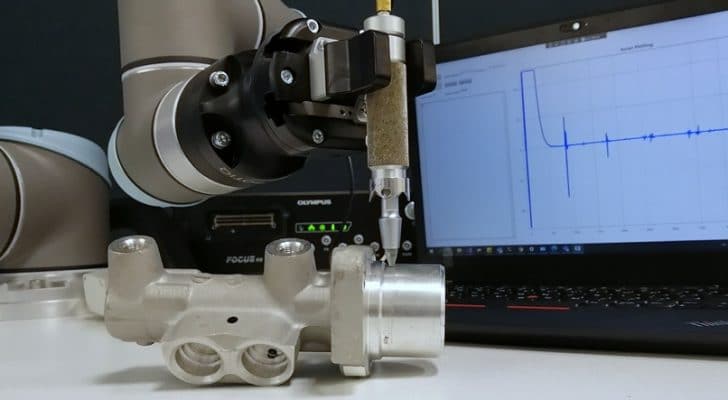

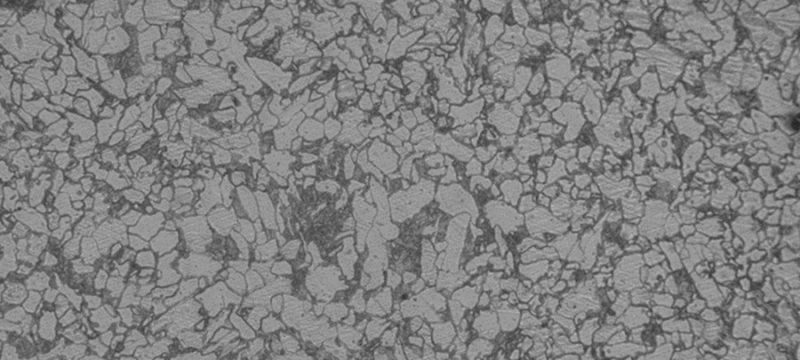

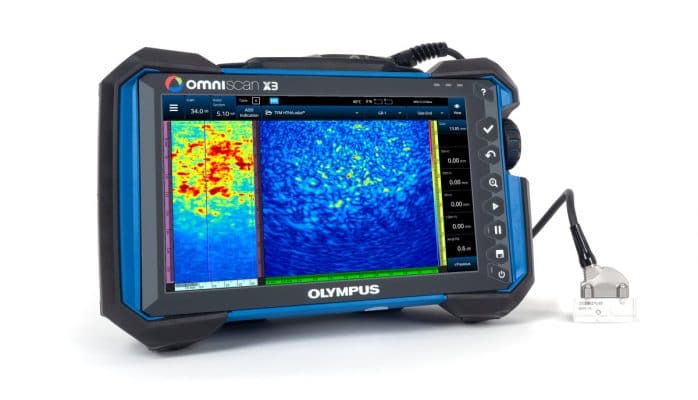

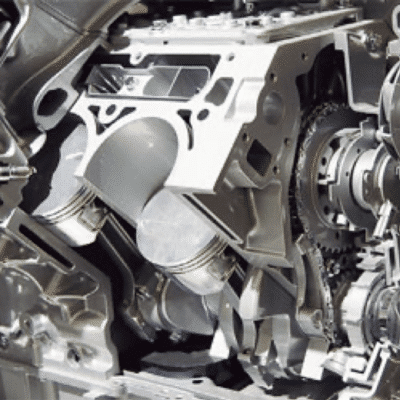

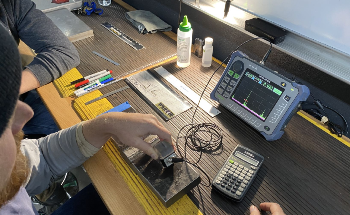

Đo mật độ hạt trong gang bằng phương pháp kiểm tra siêu âm

Bài viết này giải thích cách đo mức độ hạt trong gang và phân biệt các loại gang với gang xám. Tìm hiểu về các thiết bị và kỹ thuật kiểm tra siêu âm được sử dụng để thực hiện kiểm tra mật độ hạt trong gang mà không cần...

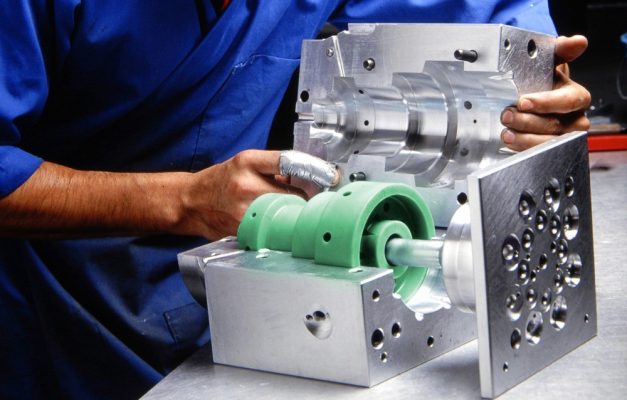

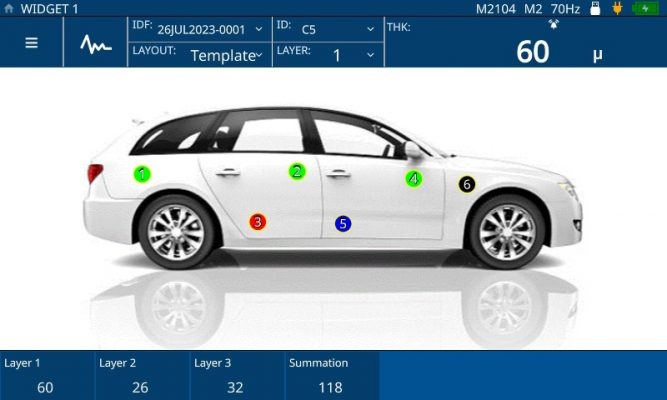

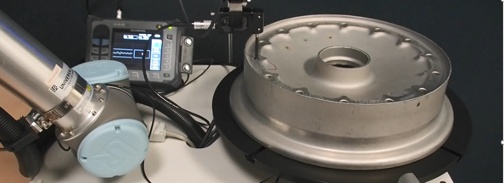

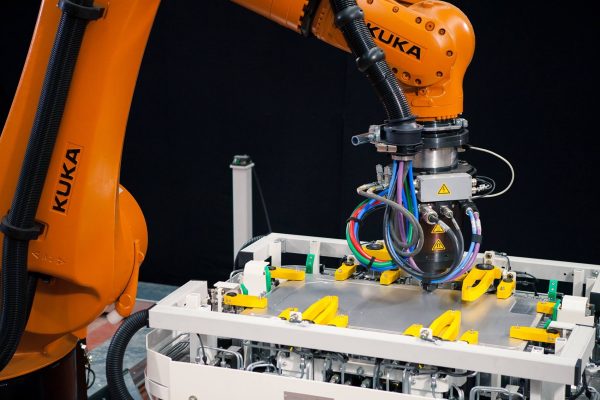

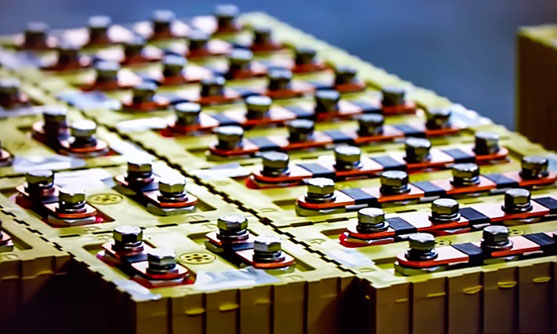

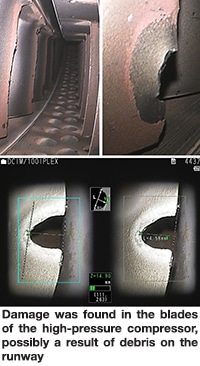

Kiểm tra biến tần xe điện (EV): Hướng dẫn thực hành tốt nhất về máy nội soi

Đảm bảo chất lượng luôn được coi là điều cần thiết trong quá trình phát triển và sản xuất ô tô, vì ngay cả những sai sót nhỏ trong linh kiện cũng có thể gây ra tai nạn nghiêm trọng. Máy nội soi công nghiệp thường được sử dụng để...

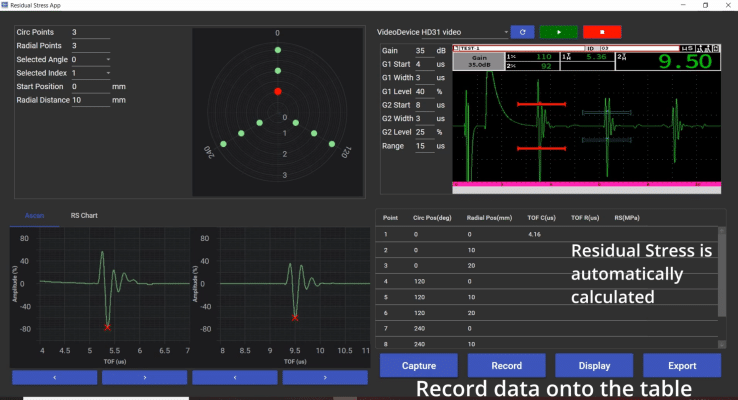

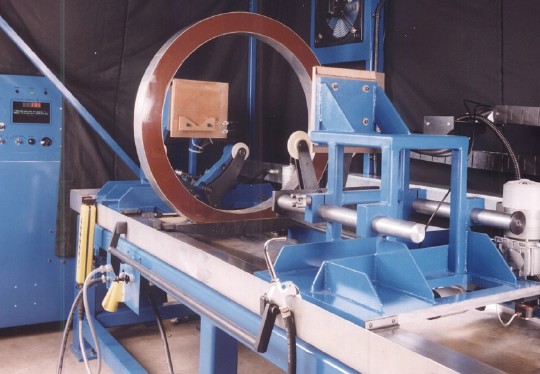

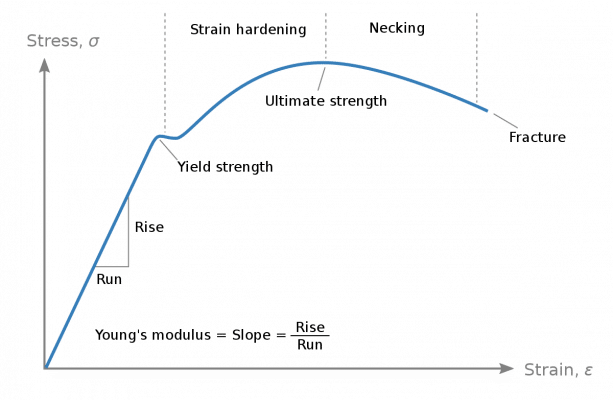

Đo ứng suất dư trong bánh xe tàu điện giúp ngăn ngừa các sự cố do hỏng bánh xe

Tham khảo thêm: Sử dụng siêu âm đo module đàn hồi trong vật liệu. Ứng suất và ứng suất dư là gì? Ứng Suất (MPa): (sức căng) là đại lượng biểu thị nội lực phát sinh trong vật thể biến dạng do tác dụng của các nguyên nhân bên ngoài...

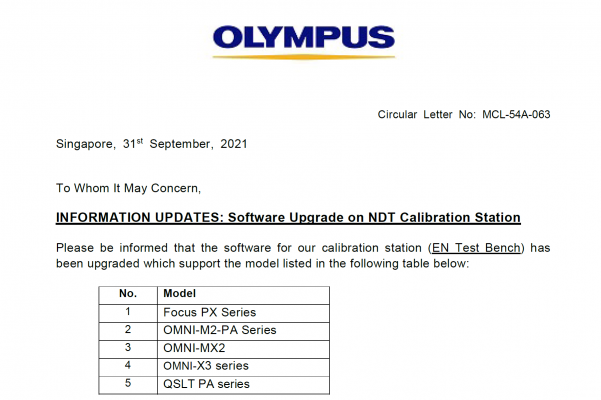

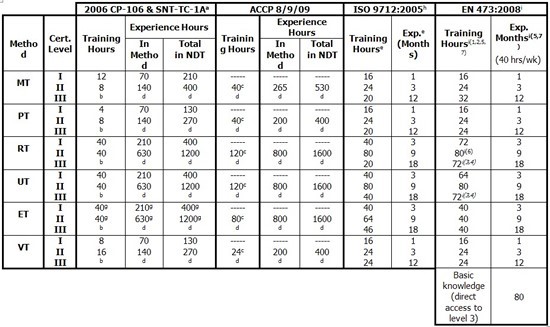

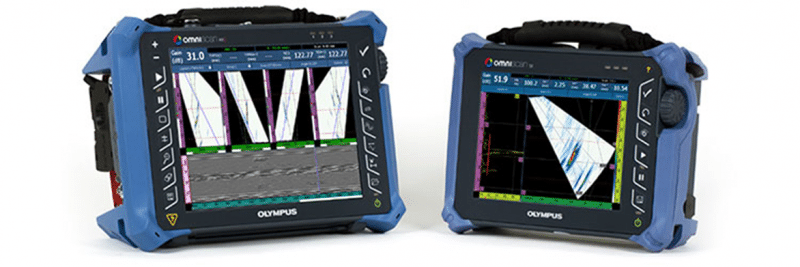

Thiết bị siêu âm: Xác thực, Xác minh và Hiệu chuẩn khác nhau như thế nào?

Xác nhận (Validation), xác minh (Verification) và hiệu chuẩn (Calibration) đều có chung mục tiêu là đảm bảo thiết bị hoạt động như dự kiến. Chúng ta sẽ thảo luận về ba quy trình có liên quan với nhau nhưng có các mục đích khác biệt này và trình bày...

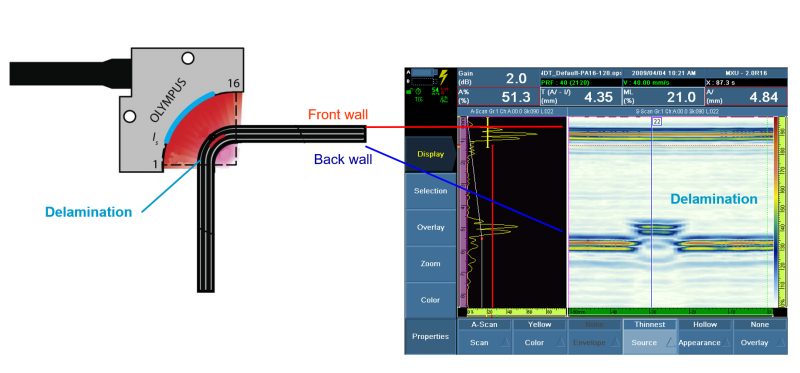

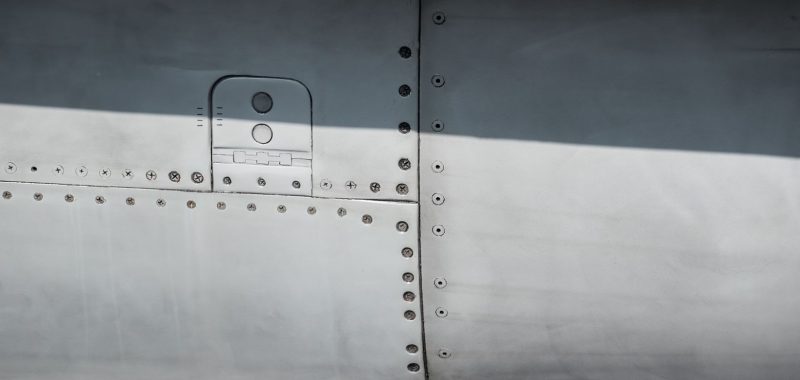

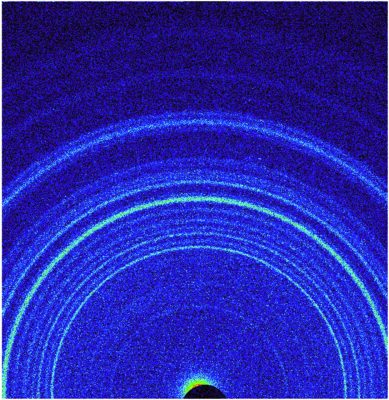

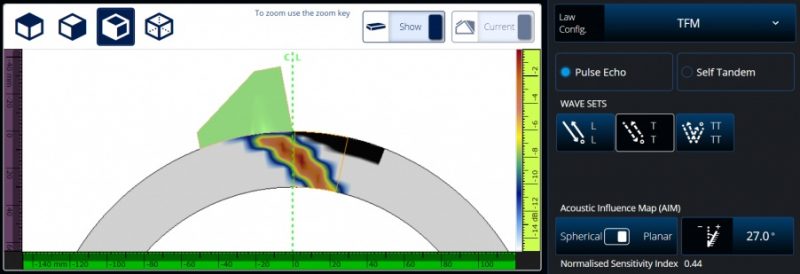

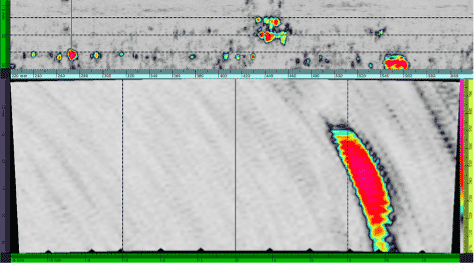

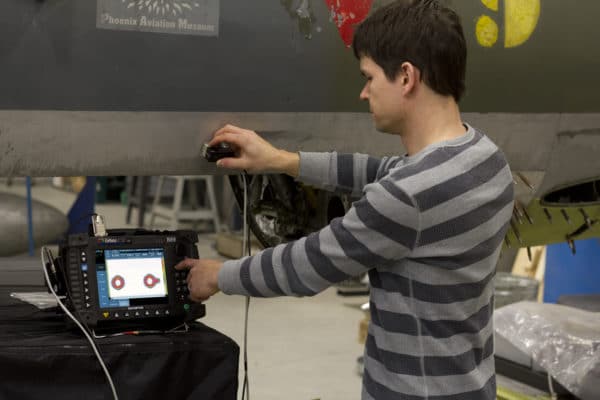

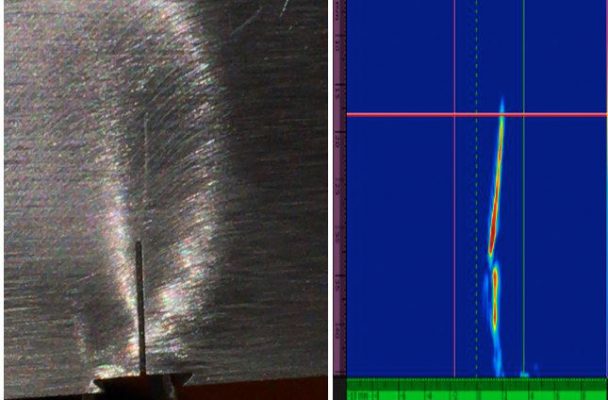

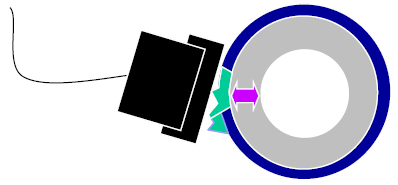

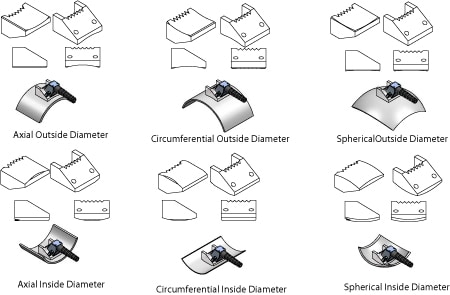

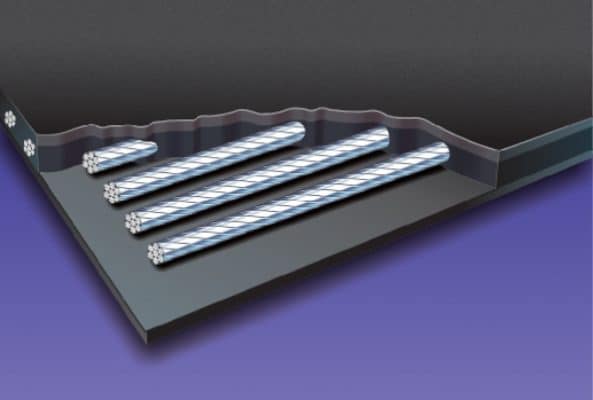

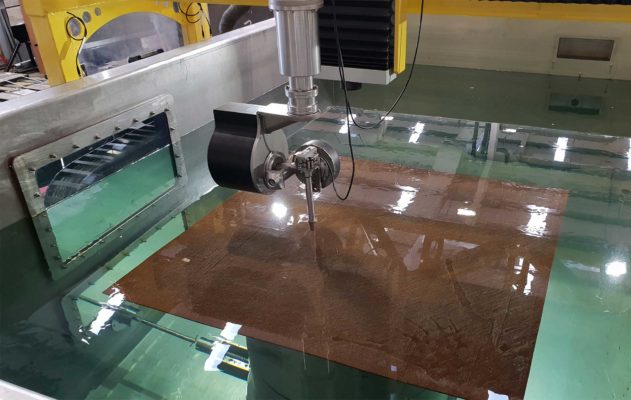

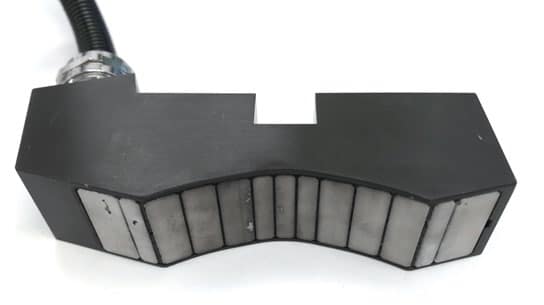

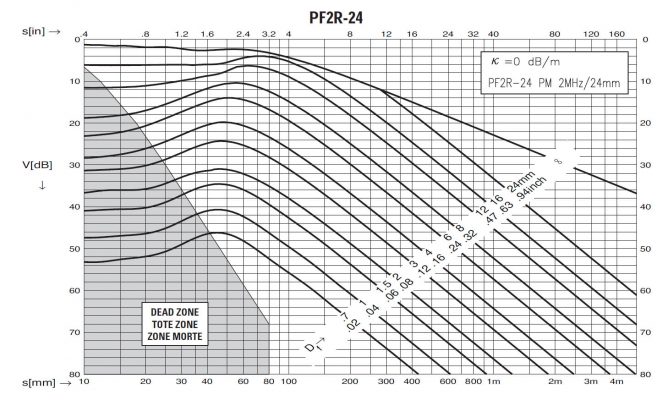

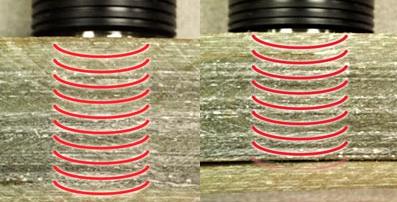

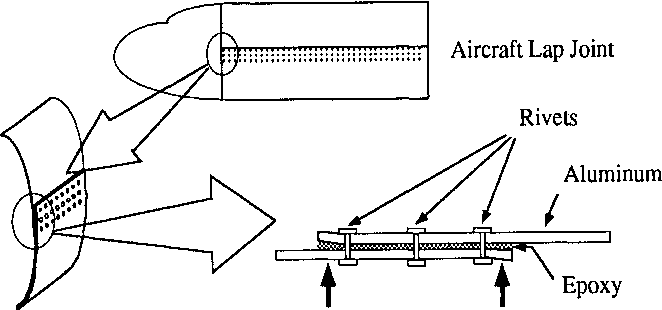

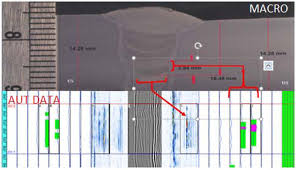

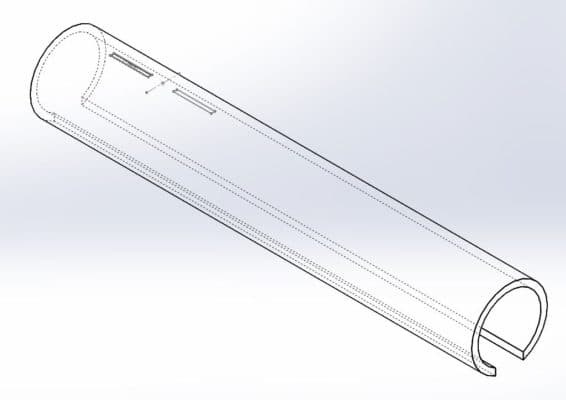

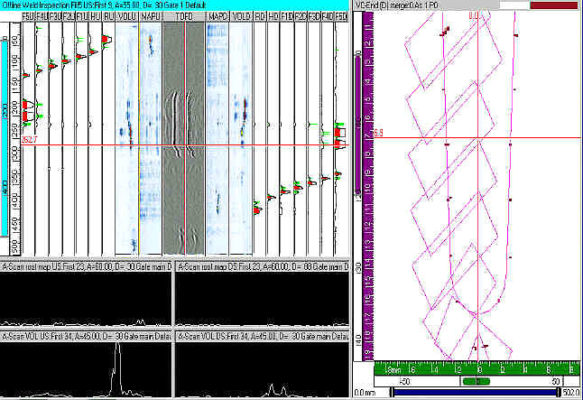

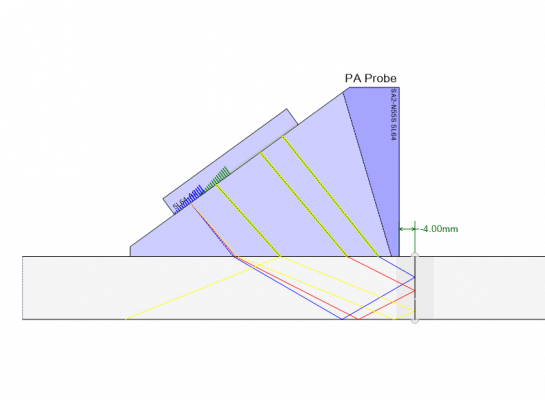

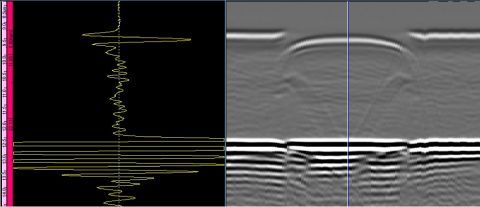

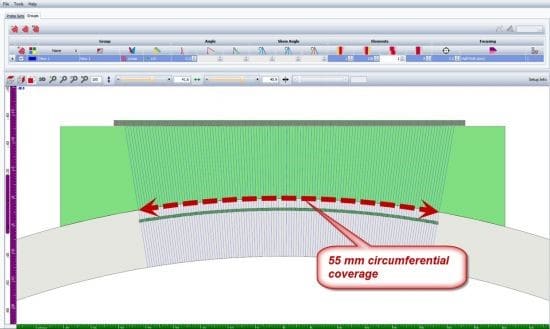

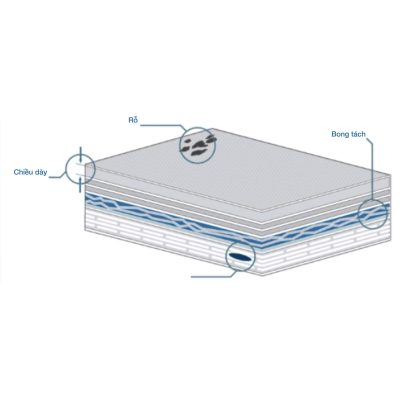

Kiểm tra siêu âm Phased Array các cấu kiện CFRP có bán kính cong sử dụng đầu dò Radii

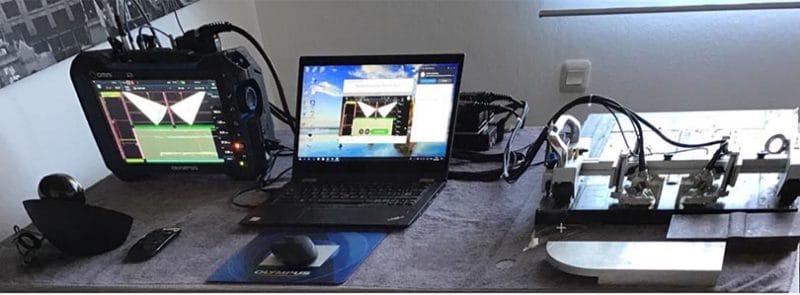

Tóm tắt Phased Array (PA) là một kỹ thuật siêu âm được sử dụng rộng rãi khi kiểm tra các bộ phận CFRP (Polyme cốt sợi carbon) trong ngành hàng không. Thiết bị thu phát PA sử dụng kèm với đầu dò đa biến tử được để tạo ra chùm...

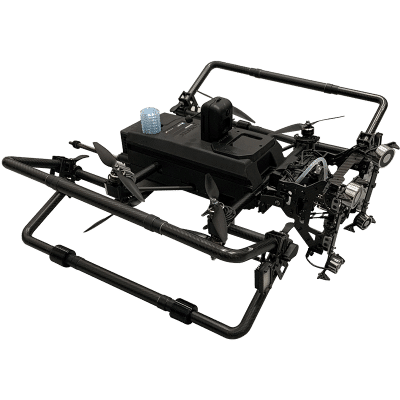

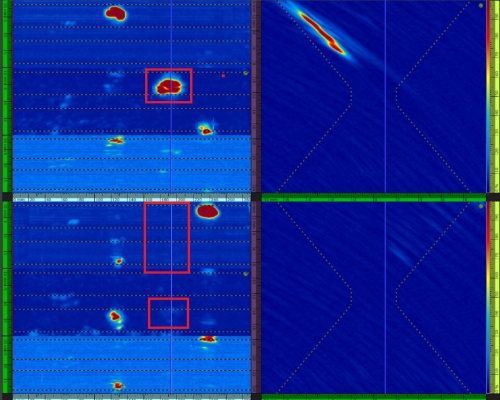

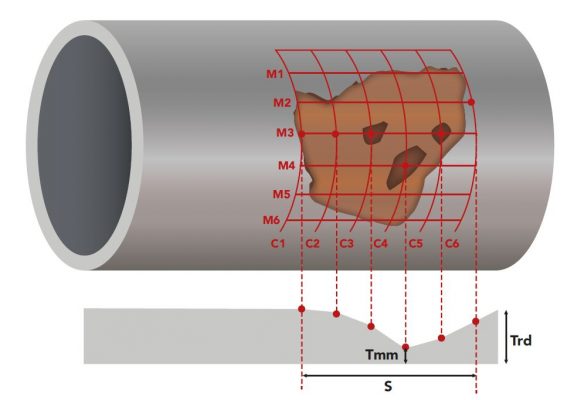

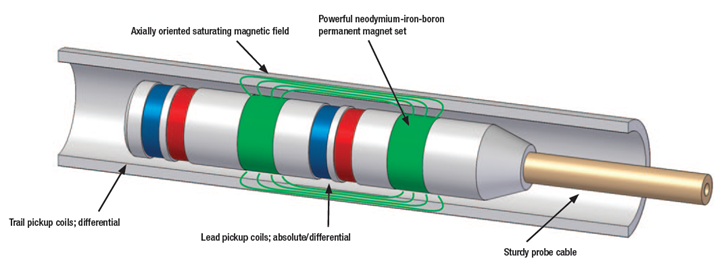

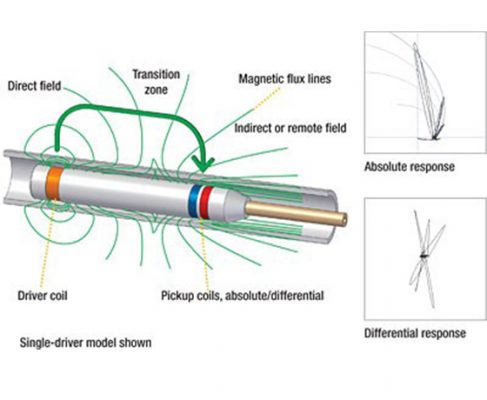

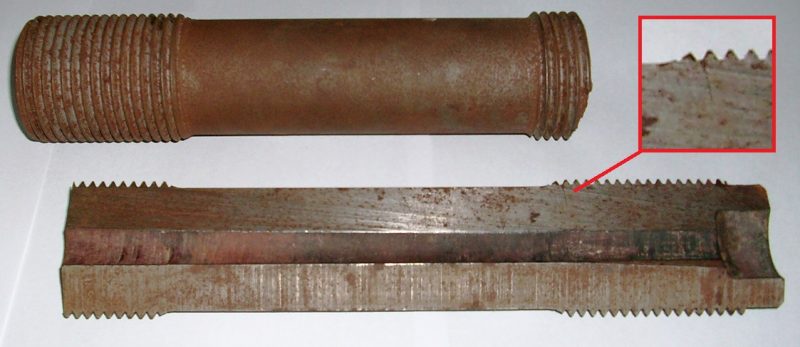

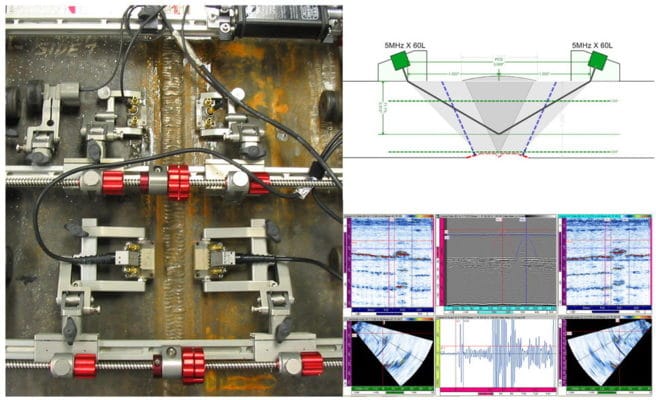

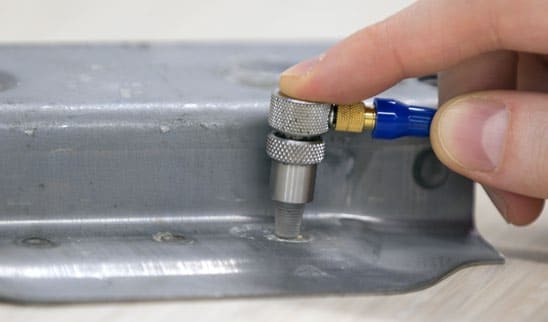

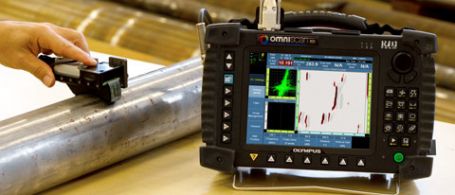

Câu hỏi thường gặp về quét kiểm tra ăn mòn sử dụng SRUT (GUL)

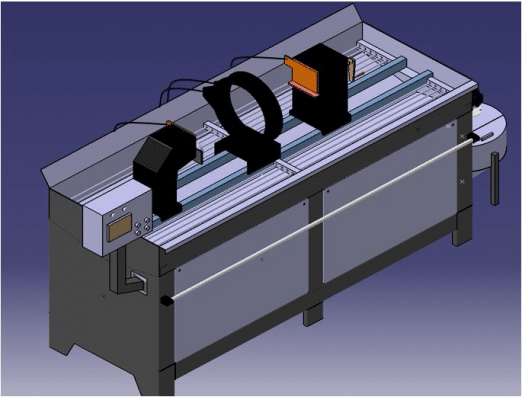

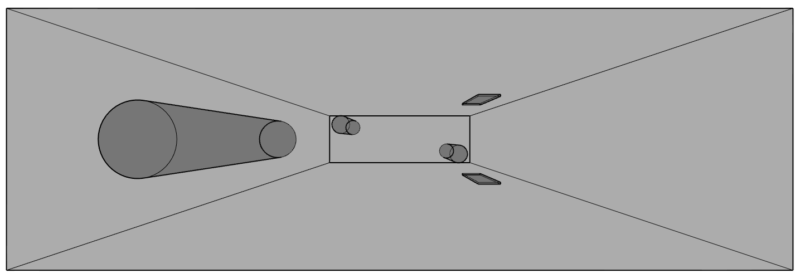

QSR1 ® là máy quét dễ sử dụng chuyên dụng để đo định lượng độ dày thành còn lại của các vị trí ăn mòn dưới giá đỡ ống. Thiết bị được đặt phía trên đường ống và tự động quét dọc theo đường ống. QSR1 ® sử dụng công...

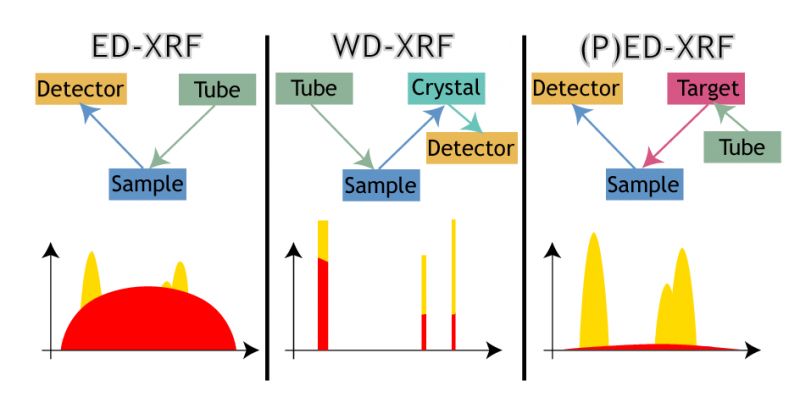

5 lý do để chọn máy phân tích Vanta™ Max và Core XRF khi cần phân tích nguyên tố

Evident đã giới thiệu thế hệ tiếp theo của máy phân tích XRF cầm tay Vanta — Vanta Max và Vanta Core. Dòng thiết bị VANTA là sự kết hợp hoàn hảo giữa hiệu suất vượt trội với sự thoải mái và khả năng kết nối được nâng cao. Được...

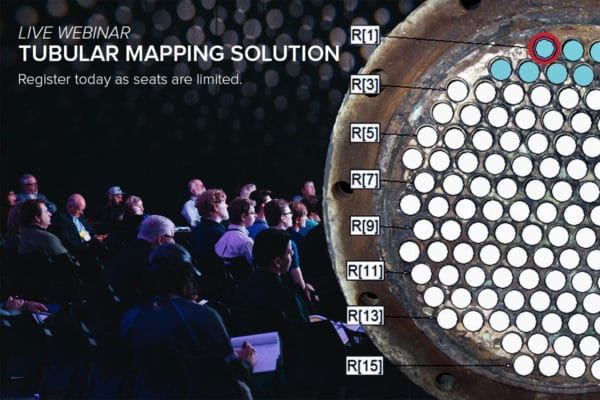

Join host Emilie Peloquin to chat with NDT experts on everything from challenging applications, new trends in the NDT industry, and tips and tricks on how to improve working with NDT your. The show wants to inspire real people, real things are using NDE to make the world safer.

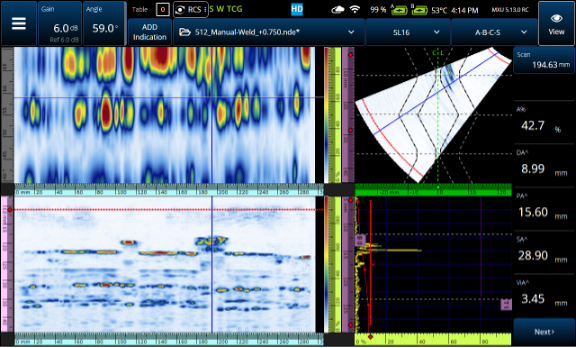

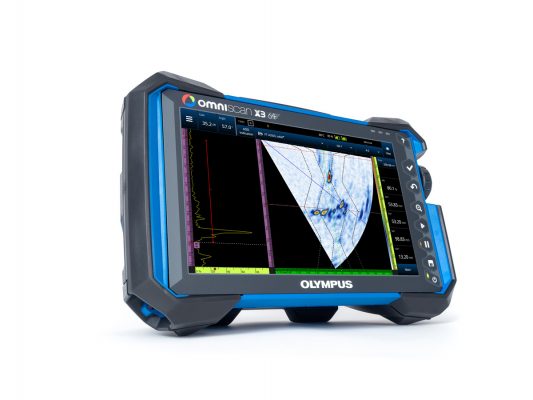

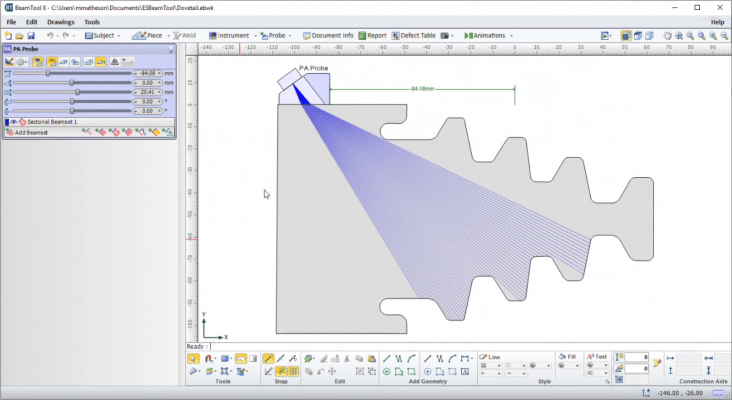

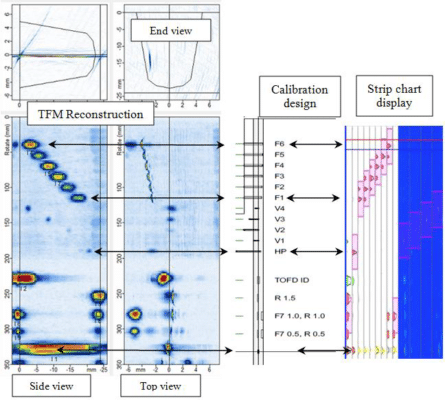

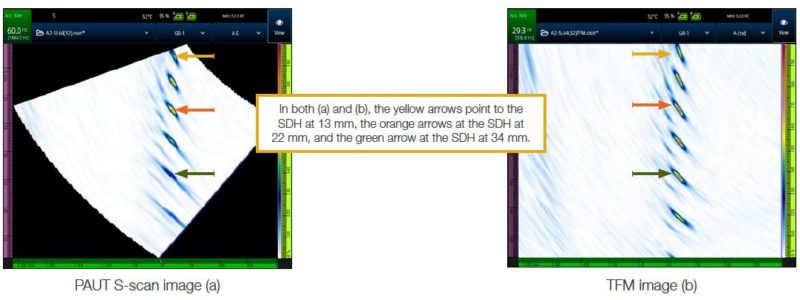

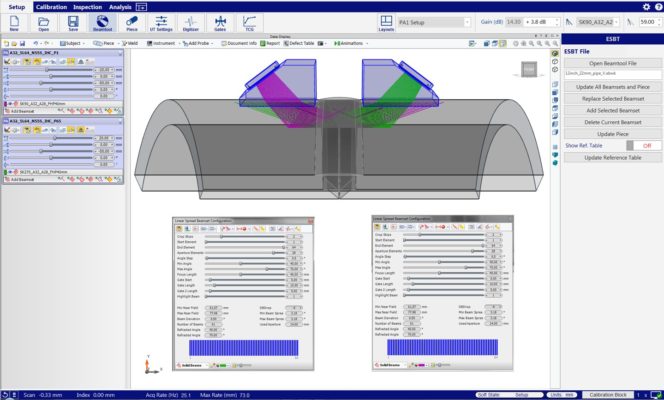

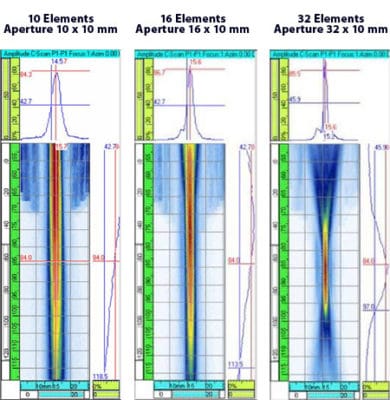

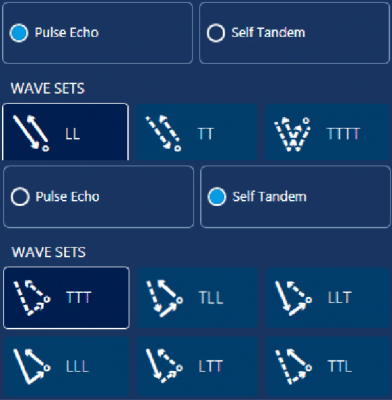

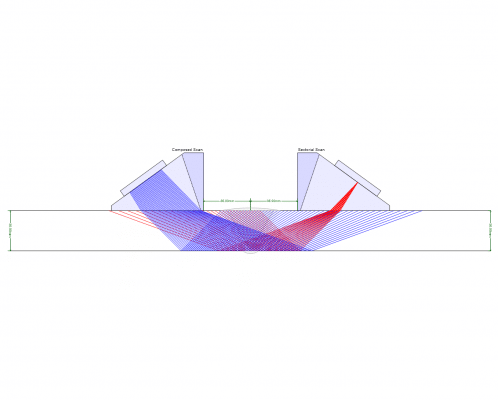

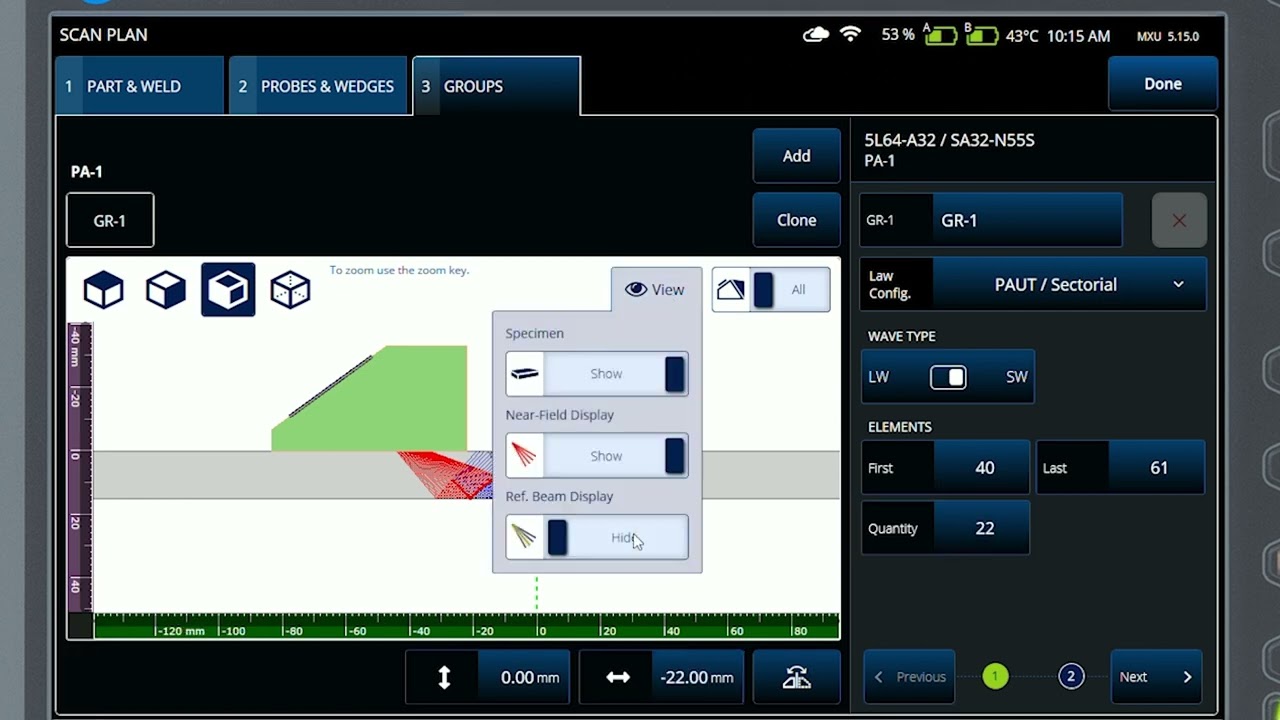

Phased Array ultrasonic testing technique

1 Comments

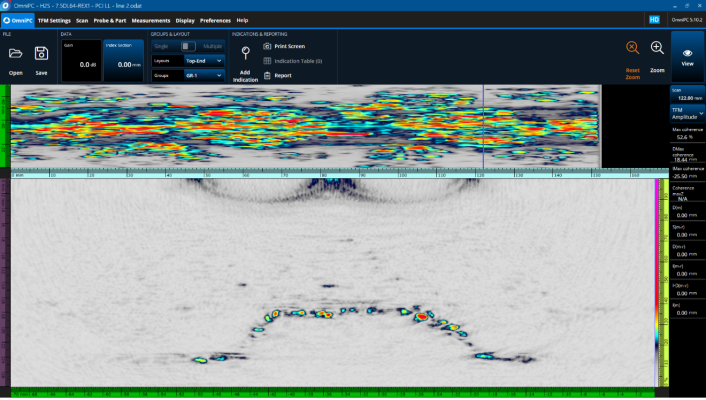

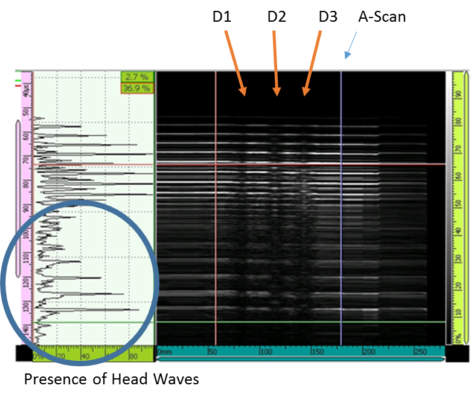

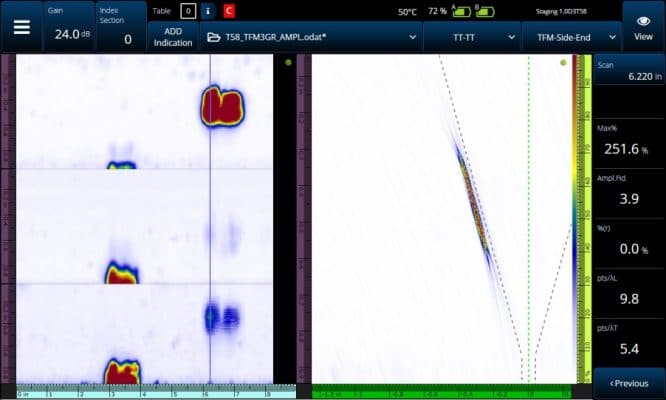

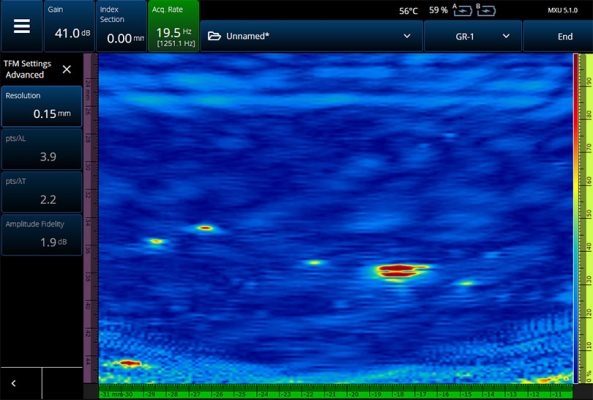

Q&A related to TFM

1 Comments

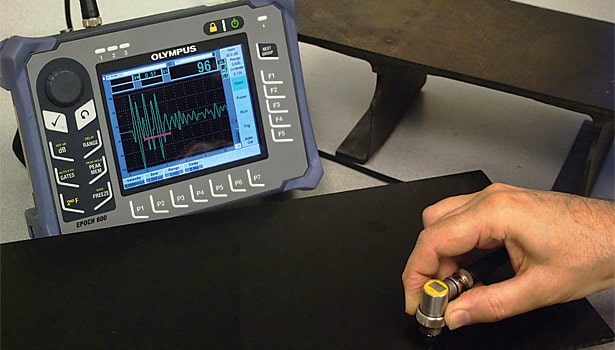

Journey of the EPOCH 6LT . device

1 Comments

VISCO NDT Scholarship Program

1 Comments