Solution from VISCO

Hundreds of industrial customers in Vietnam rely on VISCO's technology and expertise to ensure safety and quality, improve reliability and increase productivity. Drawing on more than 20 years of experience in Non-Destructive Testing (NDT), we are helping our customers solve problems that are technically responsive and cost-effective. What topic are you interested in?

List of NDT methods

We offer non-destructive inspection solutions from the most trusted brands, faster, more accurate ultrasonic inspection, higher resolution and productive digital imaging inspection, cropping ultra-precise computerized layer, automatic magnetic testing to HD resolution remote image inspection and 3D measurement, phased array eddy and eddy current testing as well as new automated ultrasonic techniques such as TFM/FMC. You can confidently push the limits of detection of any technique and take quality to the next level.

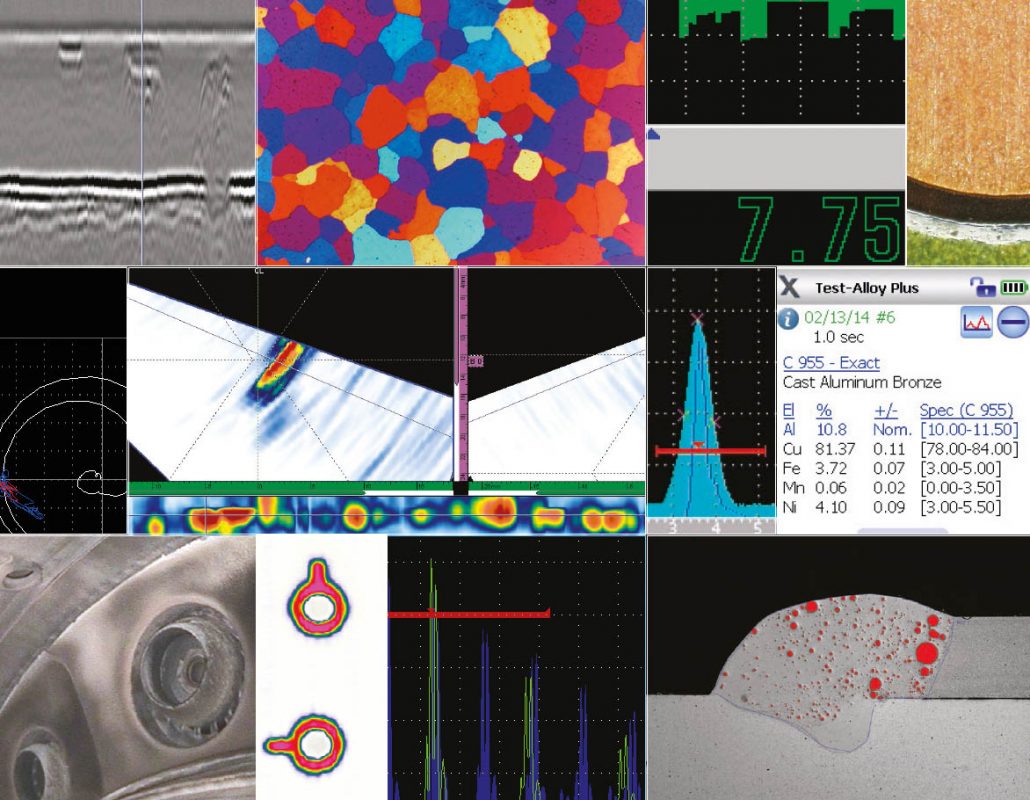

X-ray fluorescence (XRF) real-time material chemical analysis, quick alloy identification, classification, active material identification

(PMI), geoscience and hazardous substance screening (RoHS/WEEE).

- XRF analysis products.

Single and dual element transducers generate directional ultrasonic waves for use in thickness measurement, flaw inspection, and weld inspection in metals, plastics, ceramics and composites. .

- Defective ultrasound devices.

- Thickness measuring devices.

- MagnaMike glass and plastic bottle thickness gauge.

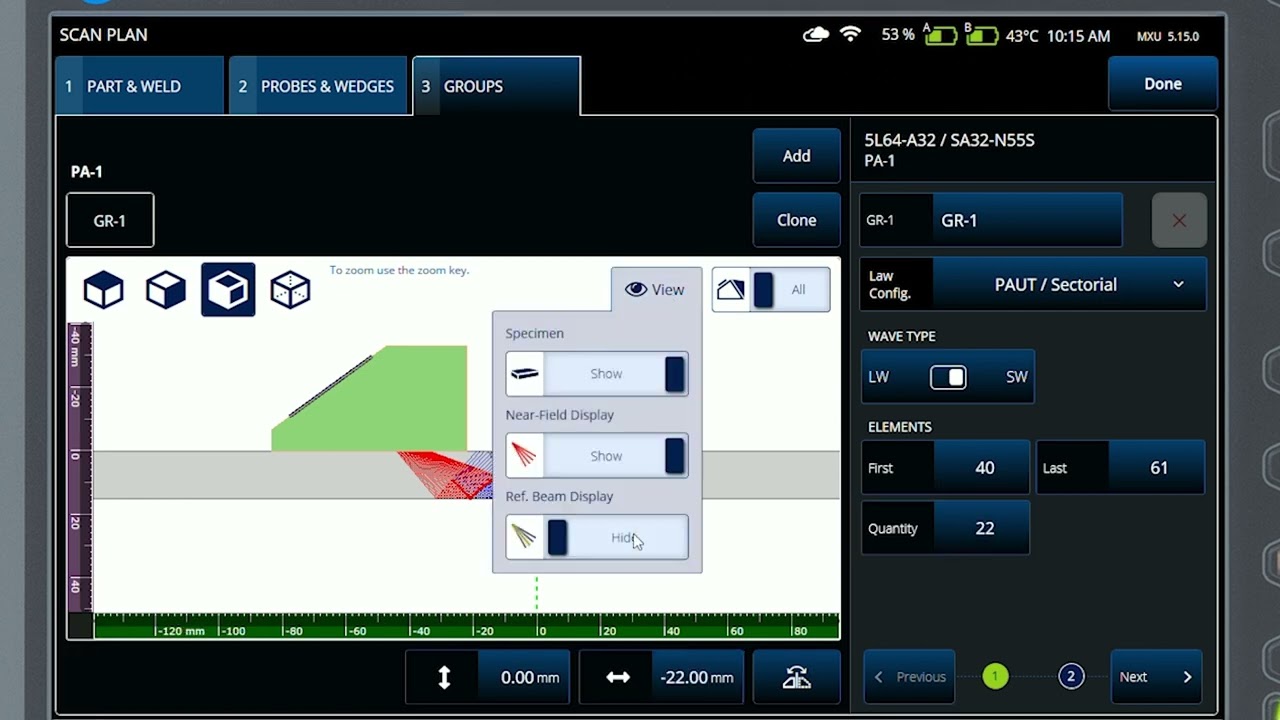

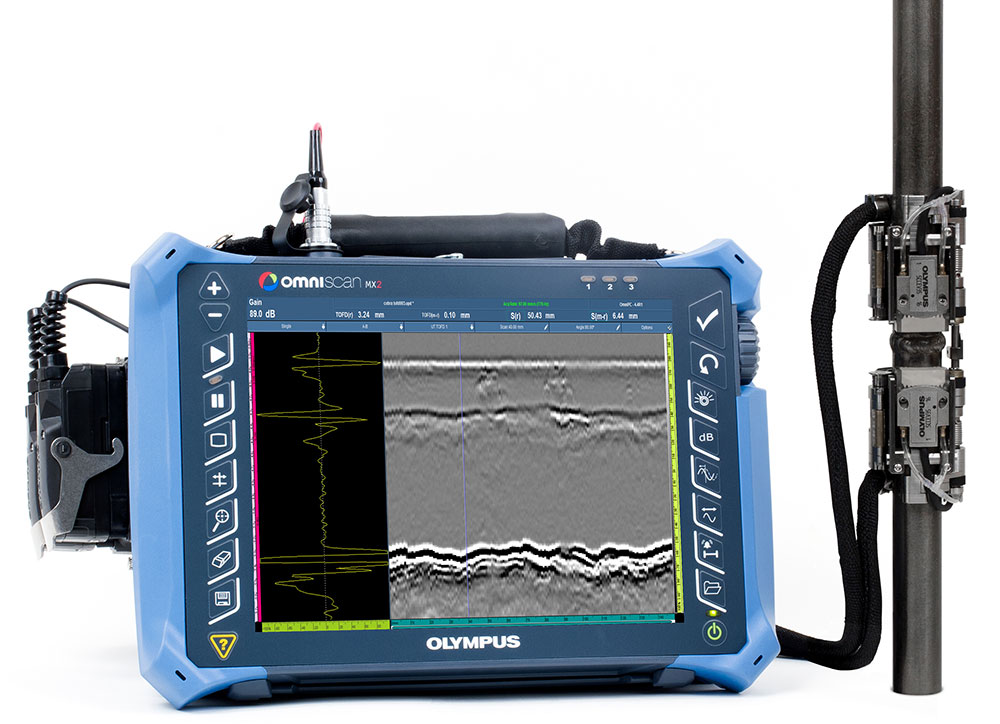

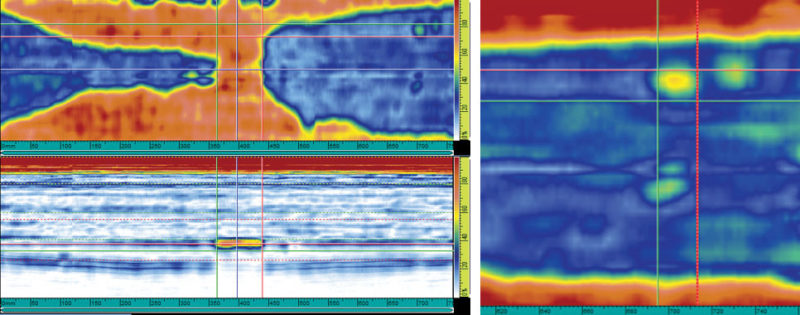

Phased array (PA) ultrasound uses multi-element probes and powerful software to direct the ultrasound beam in the specimen and capture the feedback signals, creating detailed images of internal structures material.

- Phased Array ultrasonic products.

- Phased array probe and wedge.

- Phased array ultrasonic testing accessories.

Once assembled, it is difficult to inspect the inside of a product without destroying it. Remote Visual Visibility (RVI) inspection uses a small, highly maneuverable film sensor that allows the inspector to see hard-to-reach locations.

- Product line of industrial endoscopes.

X-ray diffraction (XRD) provides the ability to quickly determine the phase and crystal structure composition and requires little sample preparation.

- Portable XRD Series.

Electromagnetic induction is used to test conductive materials. Eddy current (ECT) probes with coils generate a magnetic field that induces current to flow through the test specimen, allowing surface or near-surface defects to be detected.

- NORTEC manual eddy current products.

- Multi-technology eddy current testing equipment used for Tube testing.

Eddy Current Array (ECA) technology transmits and receives eddy current signals from multiple coils placed side by side in the same transducer. Scan wider areas with high resolution and render intuitive C-scan images.

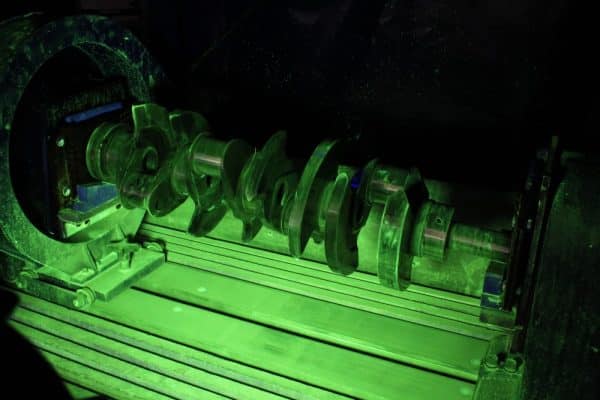

A material that is magnetized by a magnetic field or a magnet or a device such as a magnetic cuff. Small cracks on the surface and below the surface can be detected due to the magnetic powder absorption capacity of the sites that disrupt the magnetic field lines. The productivity and sensitivity of this method make magnetic particle testing the standard requirement in industrial testing.

Dye Penetrant Testing (PT), or penetrant testing, is a color dye test used to look for surface defects. PT test is suitable for a wide range of materials, but it is mainly used on non-ferrous metals. This method utilizes the principle of capillary action, where a low viscosity liquid dye is applied to the test piece and penetrates into the fracture sites on the surface.

Industrial radiography (RT) testing uses X-ray radiation or gamma sources to create images of defects hidden within materials. This technology is widely used to determine the material integrity of welds, castings, pipes, machined parts, pressure vessels and other objects. Using RT is completely non-destructive and surface preparation of the test piece usually requires little preparation.

Record high-speed movies (HSV) or play photos at slow speeds with our state-of-the-art video cameras, software and accessories. Solutions allow customers to capture motion in the highest resolution, edit and analyze, and drive research or creative projects with impressive visuals.

The Acoustic Reflection Pulse (APR) test method is one of the most effective non-destructive methods commonly used to inspect pipe components. With this technology, an audio pulse is transmitted into the tube and picked up by a microphone. The microphone picks up any interruptions in the pulse produced by reflections as determined by the properties of discontinuities in the material. This innovative inspection will detect irregularities, leaks, increase/decrease in diameter and blockages in industrial piping or heat exchangers.

Community

Designed for beginners and experts alike, Knowledge Center is the portal to the field of NDT.

Enhance your knowledge of testing tools with comprehensive training programs that help you meet specific standards. The Center also hopes to be a place to share knowledge and ideas, explore the resources below and become part of the VISCO community.

- Unit performing NDT inspection services in Vietnam.

- Training unit issuing NDT certificates in Vietnam.

- Training partner of Olympus in Vietnam.

Video