During aircraft production or maintenance, critical components are tested to see if they function correctly or as designed. Technicians must work using a variety of non-destructive techniques, so having equipment that is flexible and easy to use is important.

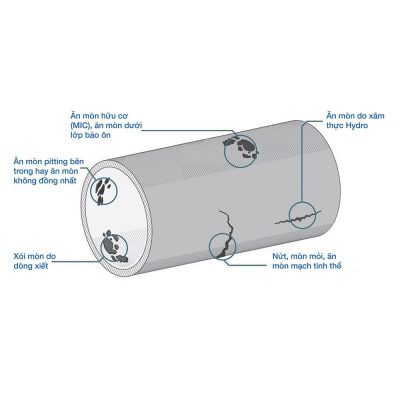

From work check the integrity of the aluminum fuselage on the aircraft from older generation devices to using technology phased array eddy currents for full inspection of complex components or find the jet engine internal damage using video inspection equipment Remote observation, technology to help people travel by plane safer.

Safety is very important in the aerospace industry, no compromise or negligence is allowed. The supervisory authorities need to ensure the highest level of safety. Companies that specialize in the certification, inspection and testing of flying vehicles and parts need to ensure and certify that they comply with the appropriate regulations, subject to strict quality control before the parts are assembled. , the maintenance schedule is followed with sufficient inspection procedures during use and operation.

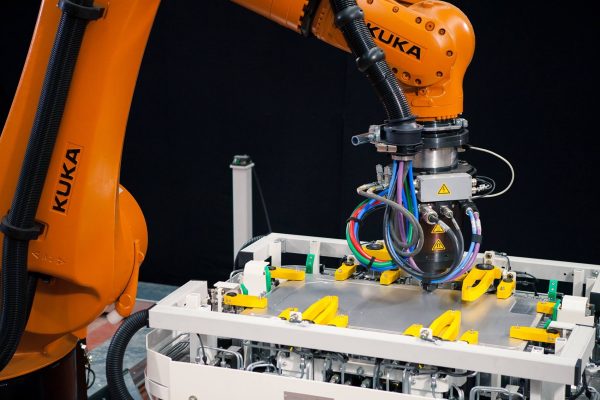

Tightening regulations in the aerospace industry are making NDT inspection more important than ever. At the same time, the pressure to reduce operating costs is increasingly intense. From aircraft engines to rocket parts, we provide smart, efficient and lean solutions to meet the challenges of both aircraft production and maintenance.

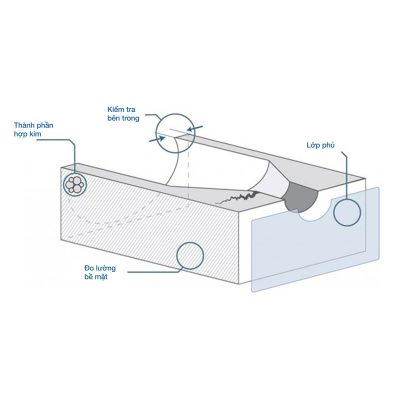

From work test new materials until Maintenance, Repair and Overhaul (MRO), Non-destructive testing (NDT) okay used for the entire life of an aircraft. We provide NDT solutions to the aerospace industry to help aircraft operators, component manufacturers, jet engine manufacturers and service companies comply with regulatory audits. Our solutions help identify defects on commercial and military aircraft.

Components production

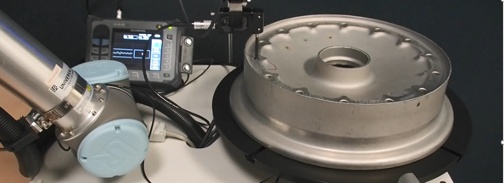

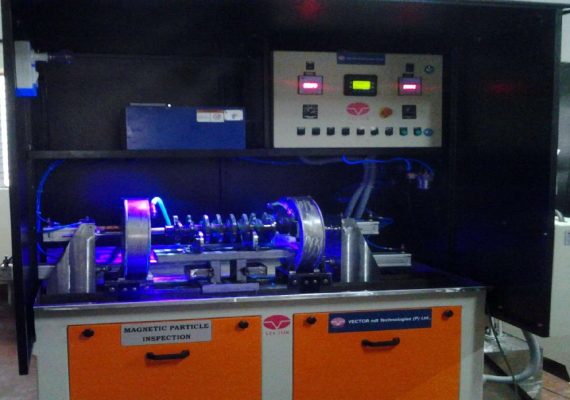

- Engine or product sample quality control.

- Quality management throughout the engine life.

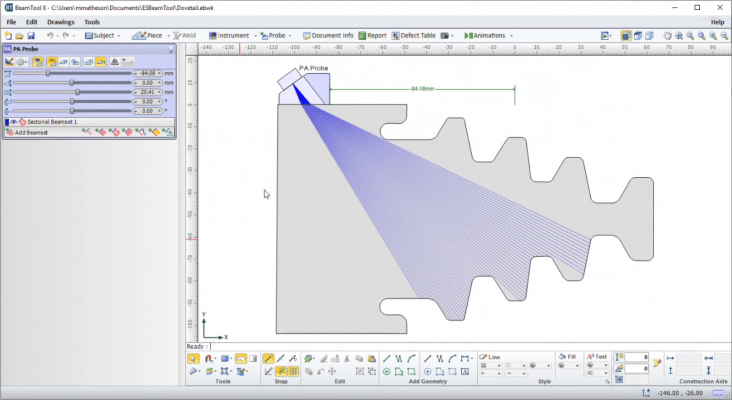

- Turbines and jet engine components (propellers, discs, etc.)

Maintenance and repair

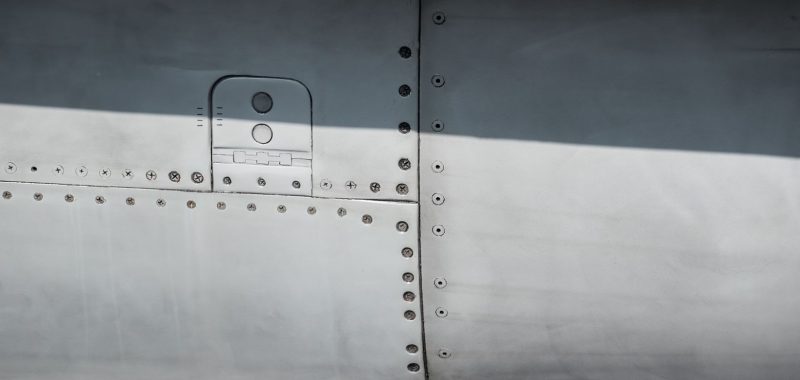

- Aircraft fuselage structure.

- Check that the body does not remove the paint with ET nice ECA.

- Cracks around screws and studs.

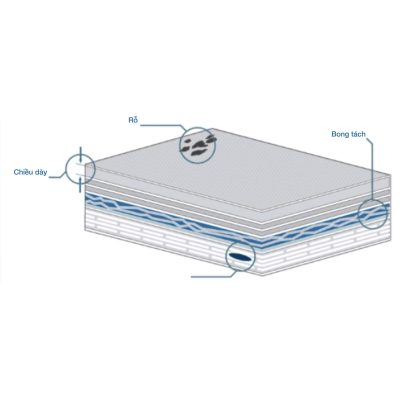

- Structure CFRP and composite.

- Drilled holes in titanium material.

- The more you land the plane.

- On-wing/Off-wing engine testing with RVI.

Aircraft manufacturer

- Quality control of incoming materials

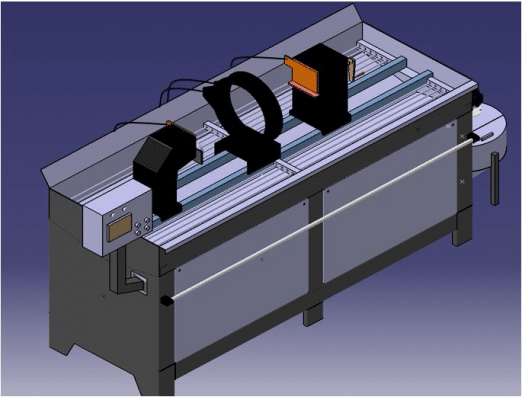

- Check the quality of complex components with an automated inspection system.

- Check the stirrer friction weld on the rocket body.

Related Posts

Related videos

Related document

Have everything 4 file, size 1.7 MiB with 3,189 lượt tải in the section Air.

Show word 1 next 4 in total 4 file.

Air

» 371.0 KiB - 747 hits - 17 September, 2021

Automated NDT inspection system for aircraft fuselage and structure

» 654.9 KiB - 858 hits - 17 September, 2021

KIT endoscopic inspection of aircraft engine turbines

» 453.9 KiB - 692 hits - 17 September, 2021

KIT inspects engine endoscopes for helicopters and small planes

» 241.2 KiB - 892 hits - 17 September, 2021

KIT for endoscopic inspection of aircraft engines of Pratt & Whitney Canada series