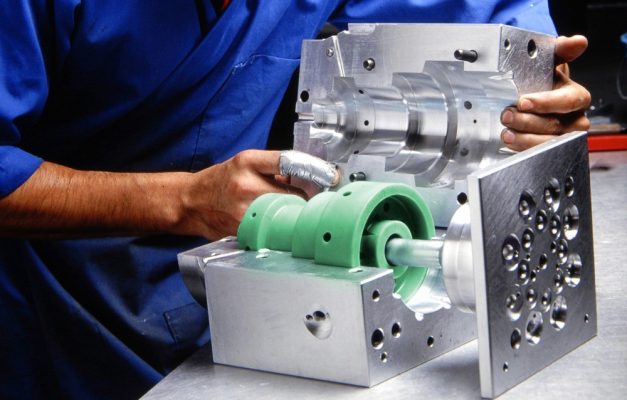

Products of the Plastics industry are diverse and increasingly used in many fields and industries. In the consumer sector, plastic products are used for packaging of all kinds, household plastic items, stationery, toys, etc. In other economic sectors, plastic products are also increasingly used; especially in some industries, plastic has also become an alternative material for traditional materials, such as in construction, electricity - electronics, etc.

Non-destructive testing in the plastics industry

Plastic is the basic ingredient that makes many products. Many manufacturers order parts and components from plastic companies that must meet specific guidelines for factors such as thickness, roughness, and structural integrity. Plastic manufacturers rely on non-destructive testing to measure properties critical to being able to meet customer needs.

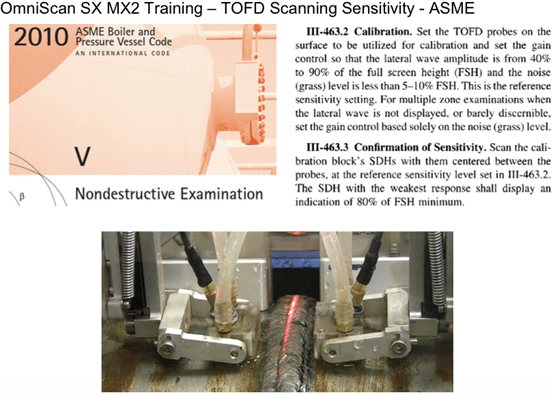

HDPE pipe weld inspection

High-density plastic (HDPE) pipes have been used to replace steel pipes in the petrochemical, energy and mining industries due to their corrosion and erosion properties. More recently, HDPE has also been used in nuclear power plants in applications involving chilled water to maintain safety. Nuclear applications require safety guarantees at the connections. Ultrasonic time-of-flight diffraction (TOFD) is commonly used for structural integrity of these thermobaric welds.

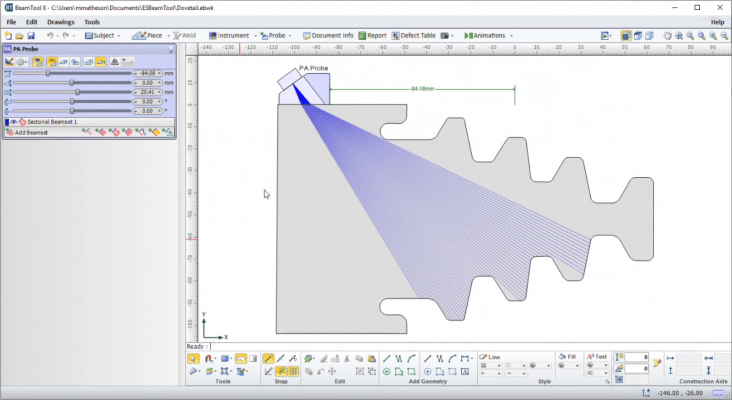

The PV-200 system is based on two ultrasonic techniques, Time of Flight Diffraction (TOFD) and Phased. While TOFD is a fast, relatively efficient technique that detects defects of any orientation and shape and is capable of accurately sizing defects, TOFD has inherent limitations in certain areas. near the top and bottom of the material. The Phased Array perfectly complements these limitations and also provides other information that makes the assessment of defects much simpler and more accurate. The PV-200 solution is often used to replace traditional radiography or ultrasound.

RoHS screening in plastic manufacturing process

For homogenous inputs or complex products, manufacturers work with suppliers to manage compliance and have measures in place to regularly test incoming materials.

Using XRF spectroscopy as a screening tool is an effective and cost-effective way to ensure that products are RoHS compliant. In addition to purchasing from RoHS-compliant sources and tracking suppliers' Certificates of Compliance, the IEC guidance recommends using XRF screening as a practical and critical verification step towards ensuring compliance. .

- Homogeneous material checks can be performed with simple and fast XRF equipment.

- Double-check supplier claims using regular screening.

- Performing on XRF assays is less expensive than other chemical analyses.

Resources

Cảnh giác với hàm lượng thạch tín trong đồ chơi squisy

Squishy là một loại đồ chơi trẻ em mềm được làm bằng bọt polyurethane có công thức đặc biệt, từ từ trở...

Phased Array ultrasonic testing technique

We are familiar with medical 3D color ultrasound examination applications, in which the wave...

1 Comments

Control the thickness of tear lines on car airbags to help ensure safety

The process of measuring the thickness of the connecting lines in the car airbag can also be applied to the measurement of...

Detecting delamination in high-voltage insulating ceramics

Verify the integrity of the bond between the silicone sheath and the composite core of the line insulation...

Measure the thickness of small diameter pipes using 38DL Plus

Application:Measurement of wall thickness and concentricity of small diameter plastic and metal pipes. Overview...

Phát hiện lỗ rỗng, co ngót trong các chi tiết nhựa đúc

Phát hiện các lỗ rỗng, co ngót hoặc các bọt khí ẩn trong các bộ phận nhựa đúc.

Wireless: A simple solution for data transmission from a thickness gauge

Quality assurance (QA) and quality control (QC) activities help companies ensure...

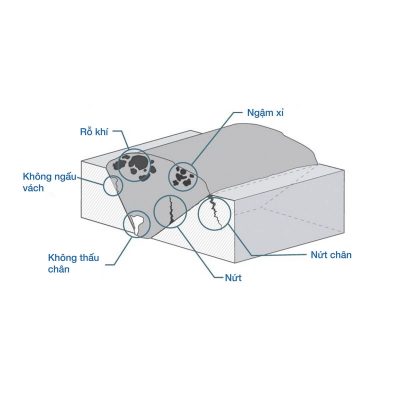

Kỹ thuật kiểm tra mối hàn nhiệt ống HDPE

Một số khía cạnh liên quan cần được xem xét khi kiểm tra TOFD mối hàn đối đầu ống HDPE. Ảnh hưởng...

Principle of measuring material thickness by ultrasonic waves

Ultrasonic thickness measurement is a widely used non-destructive testing technique for measuring...

Technical basis for testing metal hardness

What is the hardness of the material? Hardness is a property of a material, not a quantity...

Overview of the TOFD test method – Time-Based Diffraction Ultrasound

Overview of TOFD Inspection Methods TOFD is an application of ultrasound and has been used in...

Using ToFD in testing HDPE pipe heat weld

Overview of inspection of HDPE pipes Normally now, the constructors often use four methods to...

Welding inspection solutions

Welding inspection solutions Advanced solutions for the highest requirements Inspection solutions...

Measure the thickness of ultra-thin materials using a high frequency ultrasonic transducer (above 20 MHz)

The handheld ultrasonic corrosion thickness gauges use only dual element transducers and have a high frequency...

Application of the 38DL instrument in accurate thickness testing

Plastics and tanks The 38DL PLUS™ Ultrasonic Thickness Gauge can measure the wall thickness of...

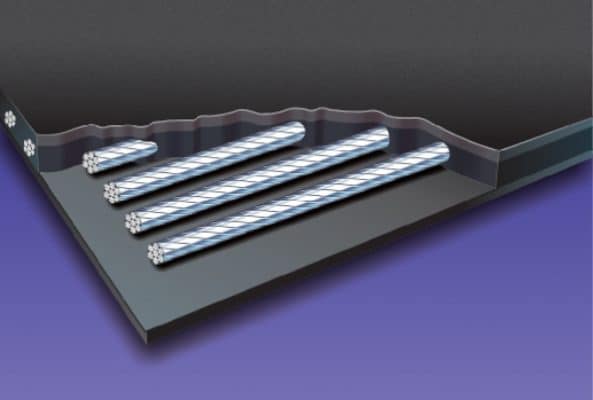

Measurement of fiber reinforcement layer depth in steel core and burlap rubber conveyor belts

Structure of steel core rubber conveyor belt Steel core conveyor belt is a product used in the ...

What is Non-Destructive Testing (NDT)? Common NDT techniques

NDT stands for Non Destructive Testing or Non-Destructive Testing refers to a series of methods...

Kiss-bond bond testing in composite materials

Introduction The demand for stronger, lighter structures in the aerospace and automotive industries...

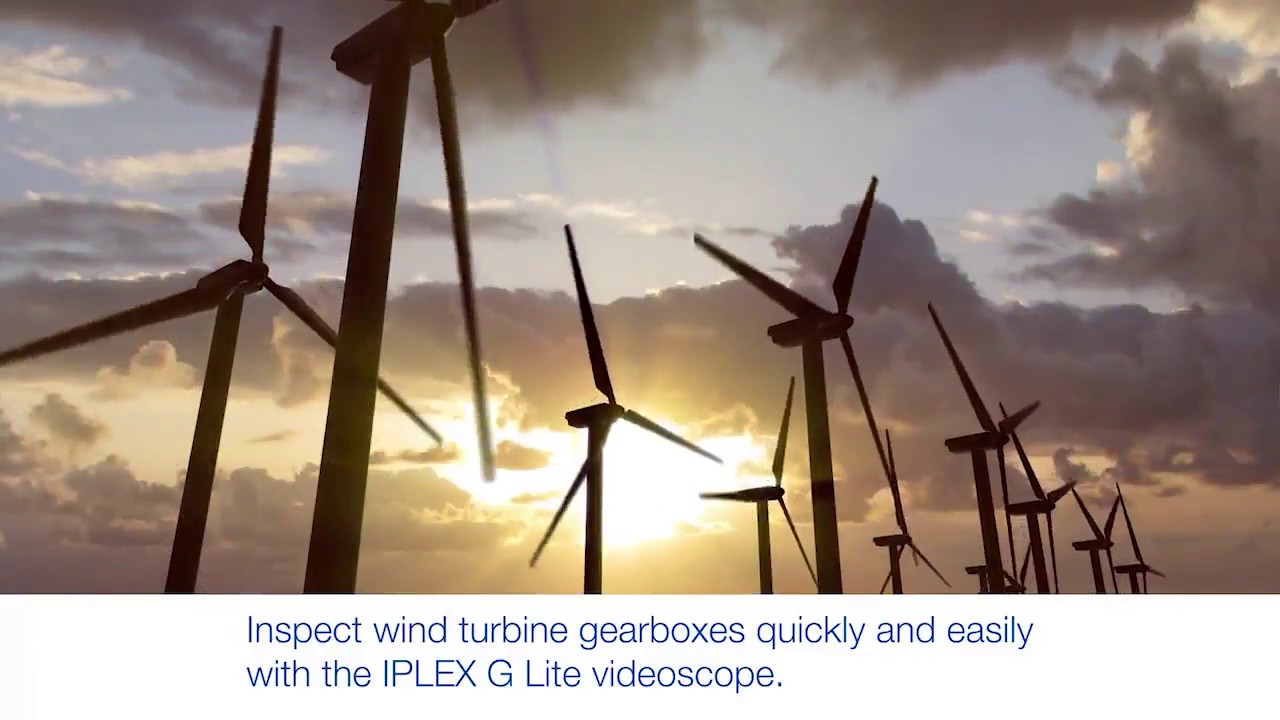

Non-destructive testing on wind turbines

As the wind power industry grows, it is increasingly important to periodically check NDT for turbines....

High temperature ultrasonic test

Although most ultrasonic flaw detectors and thickness gauges are performed at...

Video

Download

Have everything 4 file, size 5.9 MiB with 4,090 lượt tải in the section Wind power.

Show word 1 next 4 in total 4 file.

Wind power

» 302.9 KiB - 1,084 hits - 5 September, 2021

KIT IPLEX GLITE to test wind power

» 2.4 MiB - 1,073 hits - 5 September, 2021

NDT testing solutions for the wind power industry

» 843.6 KiB - 1,019 hits - 5 September, 2021

Wind power propeller inspection solution

» 2.4 MiB - 914 hits - 5 September, 2021

Technical infographic of wind power tourbine