Copper ore deposits are an important resource in the mining of copper and other valuable metals or minerals. They are often mined by large-scale, mechanized open-pit methods because of their large reserves, low quality, and shallow burial depth.

An effective method to discover porphyry copper deposits (Pocfian rocks) is to use portable X-ray analysis. In this post, we'll learn how using X-ray analysis tools to help give engineers the clues they need to mine these valuable resources and extract copper ore.

What is copper ore in porphyry rock?

Copper ore deposits in the form of Pocfian rocks are hydrated ores. The characteristics of these isoform ores include:

- Their mineralization is temporally and spatially related to neutral to acidic porous bodies

- Their formation is intrinsically related to volcanic intrusive activities

- They are characterized by certain variability and mineralization zoning

- Their ores are in distributed circuits

As a by-product of the formation of porous copper ore, clay minerals are an important guide for the discovery, exploration and exploitation of copper ore deposits.

Portable XRD analysis method for clay mineral testing

Field engineers can use a variety of hand-held X-ray analysis tools to gather real-time geological information from clay minerals. For example, an X-ray fluorescence analyzer (XRF) can determine their chemical elements, while an X-ray diffraction analyzer (XRD) handheld can display their mineralogical information. This on-site data helps geologists make faster and more accurate decisions on-site. Consider the following example.

Example: Analysis of clay minerals from Porphyry . copper mine

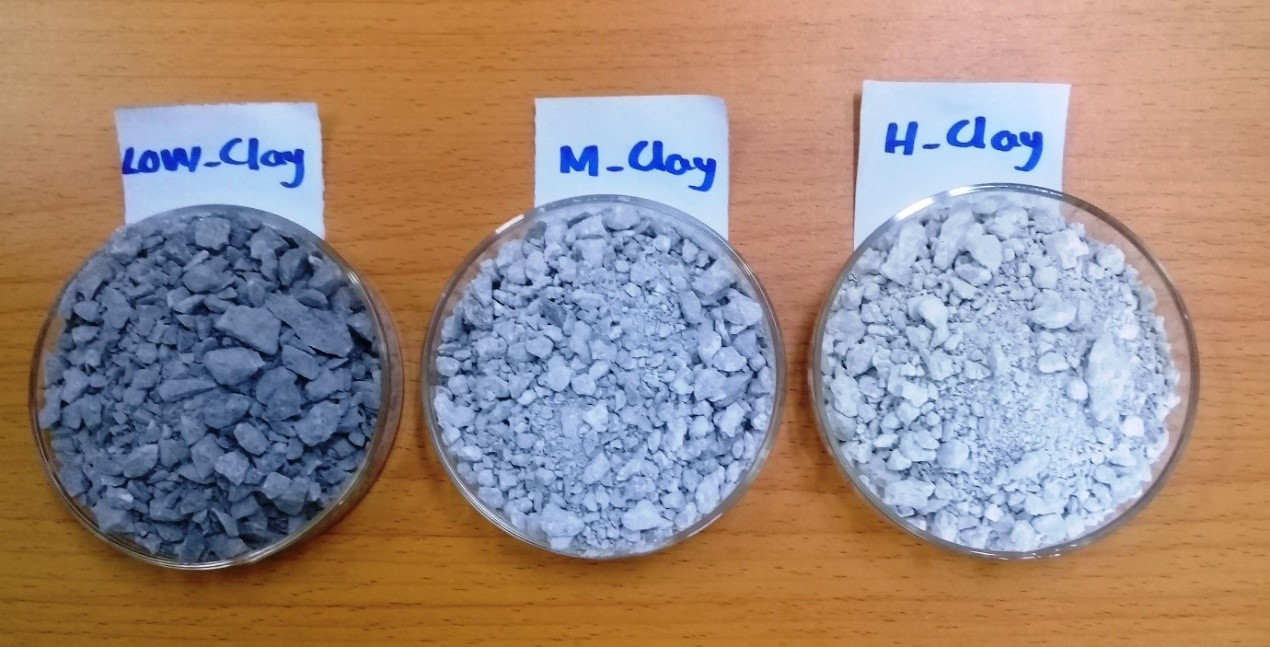

Olympus worked with engineers from a mining company to perform analysis of clay minerals obtained from a porous copper mine in Myanmar. Engineers took three mineral samples from the mine and named them high clay, medium clay and low clay (Figure 1).

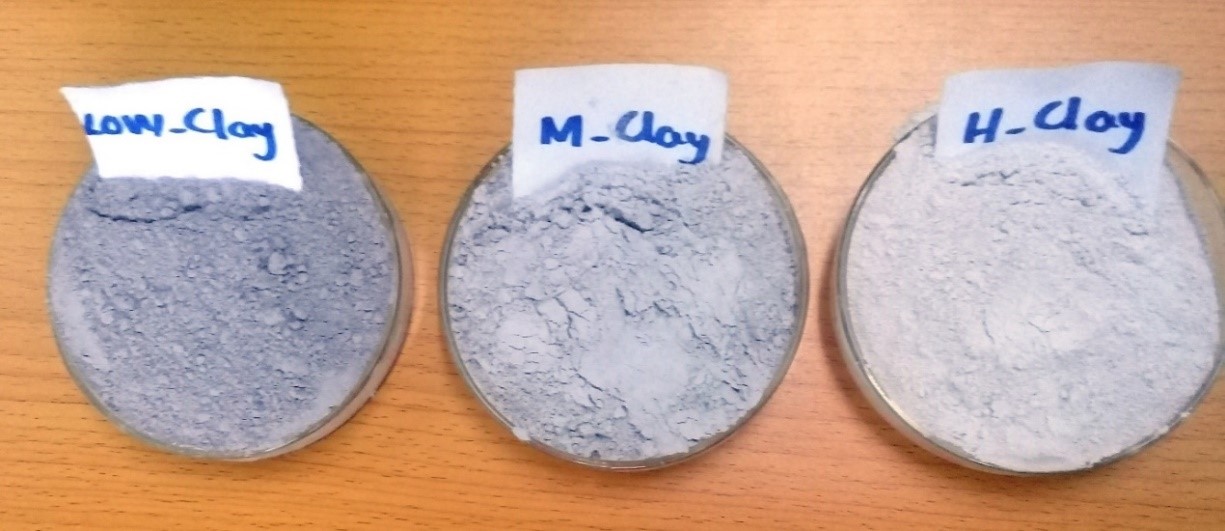

To prepare clay minerals suitable for analysis, the engineers crushed the samples to 2 mm and reduced them to about 100 g each (Figure 2).

The engineers then analyzed the crushed clay samples with portable XRF analyzer of Olympus and portable XRD analyzer to identify their chemical elements and obtain corresponding mineralogical information.

Testing clay minerals with handheld XRF

XRF test conducted using an analyzer Vanta™ OLD (VCA) equipped with a silver objective X-ray tube (Ag). Designed to operate in harsh field conditions, the rugged analyzer is IP55 rated and built to pass the US Department of Defense standard drop test (MIL-STD-810G) ). The built-in SDD sensor combined with Olympus' exclusive Axon™ Technology enables extremely high-speed detection and detection limit (LOD) is lower.

Another advantage of using a Vanta analyzer is that the sample can be analyzed immediately without any special handling. In fact, qualitative and quantitative information about the elemental composition of a sample can be obtained within 20 seconds.

In contrast, on-site laboratories often take hours or even days to provide similar analytical results. With Vanta analyzers, users can quickly obtain accurate laboratory-grade analytical data.

| Sample | Al(%) | Si(%) | P(ppm) | S(%) | Cl(ppm) | Ca(ppm) | Fe(%) | Cu(ppm) | Pb(ppm) |

| Low Clay | 1.19 | 3,66 | 311 | 3,72 | 1087 | 3378 | 3,70 | 3,70 | 210 |

| Moderate Clay | 0,83 | 3,94 | 341 | 0,90 | 2921 | 3771 | 2,34 | 1332 | 102 |

| High Clay | 0,98 | 3,95 | 422 | 0,90 | 4324 | 4062 | 1,42 | 821 | 48 |

Testing clay minerals with portable XRD analysis

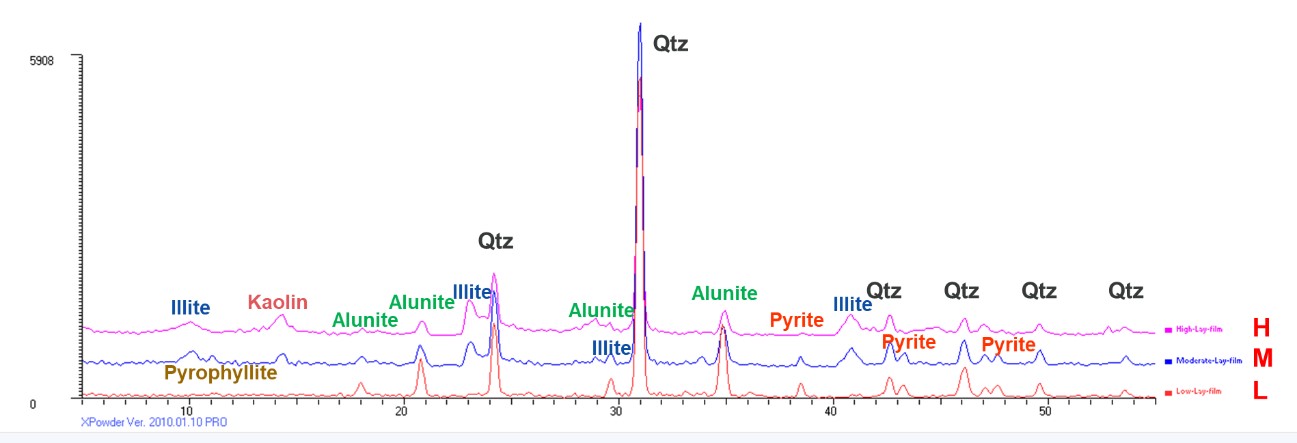

XRD test was performed with TERRA™ II . portable XRD analyzer equipped with X-ray tube with cobalt (Co) beer. The analyzer's XRD inspection capabilities combine proprietary technologies from both Olympus and the National Aeronautics and Space Administration (NASA).

The TERRA II analyzer features a unique sample loading system. Only about 15 mg of a powder sample with a 100-mesh sieve (<150 μm) is needed to collect both approximate structural (mineralogical/crystal) information and approximate elemental (chemical) information in less than a minute. full 10 minutes.

With XPowder software installed, the TERRA II analyzer can collect and process data quickly and easily. Neither the Vanta nor the TERRA II analyzers require large sample sizes or any special sample preparation. Experiments can be performed on explosive borehole samples.

| Sample ID | Quartz | Kaolinite | Pyrophyllite | Illite | Alunite | Pyrite | Total |

| Low Clay | 62.9 | – | – | – | 30.3 | 6.8 | 100 |

| Moderate Clay | 49.6 | 8.3 | 9.7 | 18.8 | 10.3 | 3.2 | 100 |

| High Clay | 45.5 | 18.7 | – | 29.8 | 6.0 | – | 100 |

By analyzing three samples (low, moderate, and high) from the porous copper mine using Olympus handheld XRF and XRD analyzers, we found that:

- The clay mineral content (mainly illite and montmorillonite) in the 3 samples gradually increased from low clay to high clay.

- The amount of quartz, alunit, pyrite decreases from low clay to high clay

This data corresponds to the mineralogical features commonly observed in the field.

The discovery of pyrophyllite formed by special transformation is also important for the exploration and extraction of porous copper ores. Elemental data (e.g. Ca, Fe, etc.) from the XRF analyzer and mineral composition data from the XRD analyzer can be mutually corroborated, helping to confirm accurate analytical results on this sample batch.