Mạnh mẽ bền bỉ tối ưu cho công việc

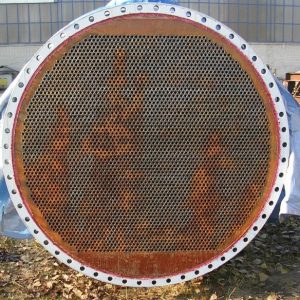

Máy phân tích XRF cầm tay Vanta™ cung cấp khả năng xác định thành phần hóa học và mác hợp kim nhanh chóng, chính xác trong các ứng dụng PMI bao gồm đường ống, van, mối hàn, linh kiện và các bồn bể chịu áp lực.

- Đảm bảo các thành phần hợp kim chính xác được lắp đặt ở những vị trí quan trọng.

- Tuân thủ Thông lệ Khuyến nghị của Viện Dầu mỏ Hoa Kỳ (API) (RP) 578 — Chương trình xác minh vật liệu cho các hệ thống đường ống hợp kim mới và đang hoạt động.

- Đánh giá khả năng ăn mòn do sulfid hóa (API RP 939-C).

- Đánh giá khả năng ăn mòn gia tốc dòng chảy (FAC).

- Nhận biết và đánh giá khả năng ăn mòn của nguyên tố còn lại trong các đơn vị alkyl hóa axit flohydric (HF).

- Tích hợp công nghệ đám mây.

Bền chắc

Máy phân tích Vanta PMI được chế tạo để kiểm tra tại ngoài hiện trường bề mặt lên đến 425°C để đạt năng suất tối đa.

Điều kiện làm việc có thể gây khó khăn đối với các thiết bị điện tử và việc hỏng hóc gây tốn kém thời gian và tiền bạc. Máy phân tích Vanta có độ bền cao, tăng thời gian hoạt động và mang lại chi phí sở hữu thấp.

Thiết bị đã thử nghiệm thả rơi bằng các phương pháp của Bộ Quốc phòng Hoa Kỳ (MIL-STD-810G), giảm nguy cơ hư hỏng và sửa chữa tốn kém khi thiết bị bị rơi hoặc va đập.

- Được xếp hạng IP55 để chịu mưa, bụi bẩn. *

- Màn trập che cảm biến trên các kiểu máy dòng C và M giúp ngăn chặn các vết đâm thủng để bạn có thể tự tin phân tích các bề mặt gồ ghề.

- Chịu được phạm vi nhiệt độ từ -10°C đến 50°C (14°F đến 122°F) ở chu kỳ làm việc liên tục. **

* Máy phân tích Dòng M được xếp hạng IP54.

** Với quạt tùy chọn. Hoạt động liên tục ở 33°C mà không cần quạt.

Đột phá

Máy phân tích XRF Vanta PMI cung cấp cho bạn kết quả chính xác giống nhau mọi lúc, từ lần thử nghiệm đầu tiên đến lần thử nghiệm thứ một trăm.

Công nghệ Axon™ độc quyền trên Vanta Series sử dụng thiết bị điện tử có độ nhiễu cực thấp cho phép đếm tia X trên mỗi giây cao hơn để có kết quả nhanh, chính xác và độ lặp lại cao.

Công nghệ Axon kết hợp với bộ vi xử lý lõi tứ mới làm cho máy phân tích Vanta phản hồi nhanh đáng kể, đẩy lùi các giới hạn về hiệu suất để bạn có được kết quả tốt nhất trong thời ngắn gian nhất. Công nghệ Axon cung cấp khả năng lặp lại thử nghiệm tốt nhất, vì vậy thử nghiệm đầu tiên cũng sẽ giống lần thử nghiệm cuối.

Công nghệ Axon cũng cung cấp giới hạn phát hiện cực thấp (LOD).

Năng suất

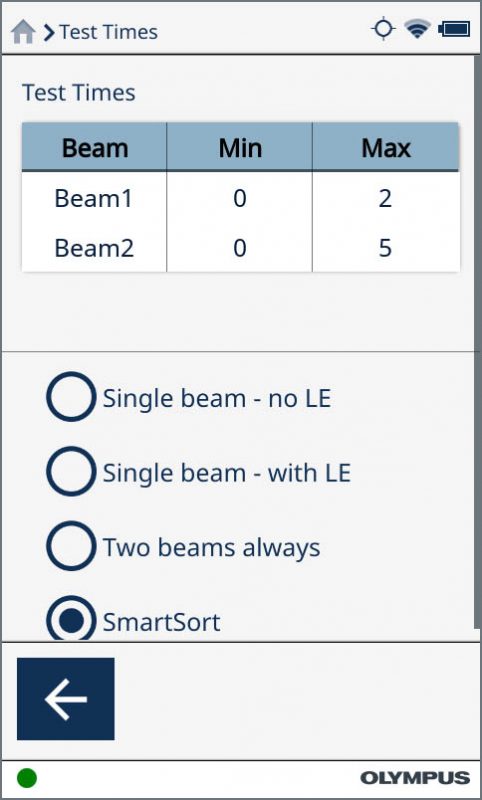

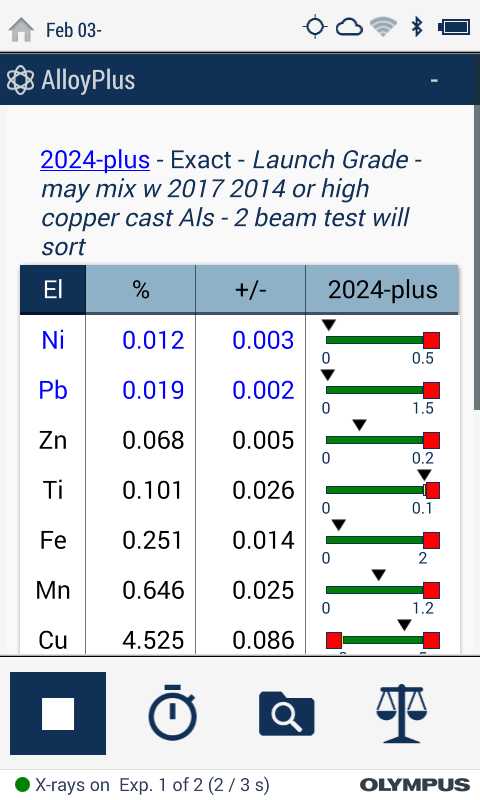

Phần mềm thân thiện với người dùng cho phép người vận hành thực hiện kiểm tra với sự đào tạo tối thiểu.

- Tích hợp GPS, camera mẫu và camera toàn cảnh để cải thiện khả năng truy xuất nguồn gốc của thông tin thử nghiệm ngoài hiện trường.

- Màn hình cảm ứng hiển thị rõ ràng, sáng và có thể đọc được trong mọi điều kiện ánh sáng.

- Giao diện người dùng trực quan dễ điều hướng.

- Tùy chỉnh các tính năng và chức năng được hiển thị trên màn hình chính.

- Xuất dữ liệu đơn giản qua ổ đĩa flash USB, mạng LAN không dây hoặc Bluetooth ®.

- Tên người dùng và mật khẩu đăng nhập duy nhất cho mỗi người dùng.

- Các nút công thái học và phím điều khiển nút bấm cấp công nghiệp giúp bạn dễ dàng điều hướng giao diện người dùng ngay cả khi đeo găng.

Tính năng phần mềm

Các tính năng phục vụ cho kiểm tra PMI

Truy nguyên và báo cáo nhanh chóng

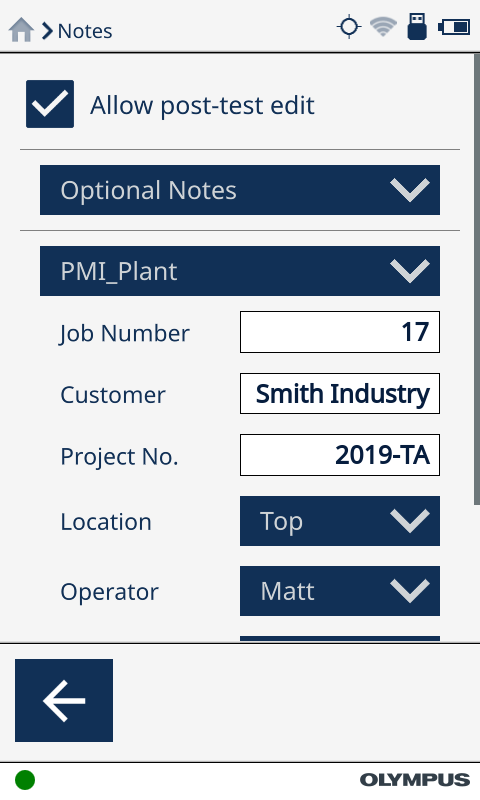

Máy phân tích Vanta™ PMI hợp lý hóa việc lưu trữ hồ sơ và truy xuất nguồn gốc để kiểm tra tại hiện trường. Người dùng có thể dễ dàng chụp và xuất dữ liệu ảnh toàn cảnh cũng như ảnh vị trí kiểm tra.

- Camera toàn cảnh 5 megapixel và camera nhắm tùy chọn

- GPS tích hợp

- Dấu ngày / giờ tự động

- Các mẫu nhãn dữ liệu tùy chỉnh cho từng dự án, công việc hoặc nhà cung cấp

- Kết nối LAN không dây và Bluetooth ® tùy chọn

Thư viện cấp hàn

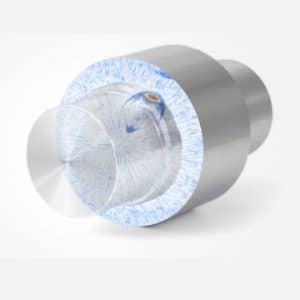

Thư viện cấp mối hàn giúp dễ dàng xác minh thành phần hóa học và cấp của mối hàn. Camera điểm chụp 3 mm (tùy chọn) cho phép người kiểm tra phân tích chính xác và đúng vị trí:

- Mũ mối hàn mỏng và tách biệt với vật liệu cơ bản

- Mối nối kim loại

- Hợp kim

- Các thành phần cố định kích thước nhỏ

- Dây hàn

- Thiếc hàn

Nguyên tố dư và nguyên tố vãng lai

Đặt hàm lượng tối đa cho các nguyên tố còn lại trong các nhóm vật liệu để khớp kết quả phù hợp nhanh chóng, chính xác.

So sánh các cấp hợp kim gần nhau để biết hợp kim nào phù hợp nhất với các giá trị danh nghĩa và các nguyên tố tồn dư:

- Tự động xác định sự hiện diện của các nguyên tố không nhìn thấy được với XRF dựa trên thông số kỹ thuật cấp hợp kim

- Xác định sự hiện diện của các nguyên tố nhiễm bẩn / tồn dư trong kim loại tái chế có thể ảnh hưởng đến giá trị và / hoặc các yêu cầu xử lý từ nguồn

- Đặt hàm lượng tối đa cho các nguyên tố còn lại trong các nhóm cấp hợp kim

- Gắn cờ các nguyên tố vãng lai và mức độ nhiễm

Tuân thủ Chương trình Xác minh vật liệu tích cực

Đối với các chương trình xác minh vật liệu, máy phân tích Vanta PMI được sử dụng để xác nhận vật liệu xây dựng, xác minh vật liệu dựa trên các báo cáo kiểm tra vật liệu và xác định các vật liệu được đánh dấu không phù hợp.

- Xác nhận vật liệu xây dựng

- Xác minh vật liệu dựa trên chứng chỉ nhà máy và báo cáo thử nghiệm vật liệu

- Xác định vật liệu không theo dõi được hoặc được đánh dấu không phù hợp

Tải catalog

Có tất cả 18 file, kích thước 30,2 MiB với 28.044 lượt tải trong mục VANTA.

Hiển thị từ 1 tới 18 trong tổng số 18 file.

VANTA

» 11,9 MiB - 0 hits - 3 Tháng 4, 2024

» 4,3 MiB - 1.588 hits - 16 Tháng 12, 2021

Ứng dụng XRF trong công nghiệp chế tạo ô tô

» 1,8 MiB - 2.364 hits - 16 Tháng 12, 2021

Ứng dụng XRF và XRD trong khoa học địa chất

» 250,2 KiB - 1.665 hits - 16 Tháng 12, 2021

Infographic ứng dụng XRF trong lĩnh vực khai thác khoáng sản

» 183,3 KiB - 1.753 hits - 1 Tháng 1, 2000

» 916,7 KiB - 1.605 hits - 16 Tháng 12, 2021

Giải thích nguyên lý XRF hoạt động dưới dạng hình ảnh (Poster treo tường)

» 2,4 MiB - 1.923 hits - 16 Tháng 12, 2021

Ứng dụng XRF phân tích đất giàu sắt ở Eeherrin, Virginia

» 1,6 MiB - 1.615 hits - 16 Tháng 12, 2021

Giới thiệu nhanh thiết bị VANTA XRF (4 trang)

» 1,4 MiB - 1.618 hits - 16 Tháng 12, 2021

Giới thiệu VANTA XRF trong lĩnh vực môi trường

» 1,3 MiB - 1.567 hits - 16 Tháng 12, 2021

Giới thiệu Vanta XRF xác nhận vật liệu trong QA/QC

» 633,2 KiB - 1.862 hits - 16 Tháng 12, 2021

Giao diện lập trình ứng dụng với VANTA ứng dụng trong kiểm tra XRF tự động

» 441,0 KiB - 1.754 hits - 16 Tháng 12, 2021

Giới thiệu công nghệ Axon đột phá giúp kiểm tra nhanh và kết quả ổn định trên thiết bị VANTA XRF

» unknown - 0 hits - 21 Tháng 5, 2018

» 274,1 KiB - 1.606 hits - 16 Tháng 12, 2021

Vanta XRF qua các con số

» 217,6 KiB - 1.703 hits - 16 Tháng 12, 2021

Sử dụng VANTA XRF trong phân tích kim loại quý bộ xúc tác khí thải ô tô (tái chế)

» 353,9 KiB - 1.589 hits - 16 Tháng 12, 2021

Ứng dụng Vanta XRF trong công nghiệp sản xuất Xi măng

» 1,3 MiB - 1.813 hits - 2 Tháng 2, 2024

Catalog dòng sản phẩm VANTA (Tiếng Anh)

» 1,0 MiB - 2.019 hits - 2 Tháng 2, 2024

Catalog dòng sản phẩm VANTA (Tiếng Việt)