Độ bền cho thời gian hoạt động tối đa và khả năng sinh lời

Máy phân tích XRF cầm tay Vanta ™ trong công nghiệp tái chế và phân loại phế liệu được xếp hạng IP55 để chịu được mưa, bụi bẩn và được thử nghiệm rơi bằng phương pháp của Bộ Quốc phòng Hoa Kỳ (MIL-STD-810G) giúp ngăn ngừa sự cố và tối đa hóa thời gian hoạt động. *

Mỗi máy phân tích Vanta sử dụng phân loại phế liệu đều được tối ưu hóa với các tính năng phần mềm được thiết kế để cải thiện lợi tức đầu tư và giúp các chủ bãi phế liệu đảm bảo thu lời khi sử dụng thiết bị.

- Thiết bị đi kèm với công nghệ Axon độc quyền và sáng tạo để bạn có được câu trả lời phù hợp nhanh chóng, cho năng suất và thông lượng cao.

- Tích hợp công nghệ đám mây

Gói tiêu chuẩn gồm 25 nguyên tố chính, tự tin đo nhiều loại hợp kim và kim loại:

- Hợp kim màu

- Thép hợp kim thấp

- Hợp kim nhôm nhẹ

- Đồng

- Kim loại quý

- Chất xúc tác trong ống xả ô tô

- Thiết bị điện tử

- Thủy tinh

* Máy phân tích M Series được xếp hạng IP54.

Bền chắc

Bãi phế liệu là môi trường thử thách đối với các thiết bị điện tử, và các hỏng hóc trên thiết bị có thể gây ra sự cố gây tốn kém thời gian và tiền bạc. Máy phân tích Vanta được chế tạo để có độ bền cao và bền bỉ nhằm tăng thời gian hoạt động và chi phí sở hữu thấp.

Để bảo vệ bổ sung, các máy phân tích được thử nghiệm rơi (MIL-STD-810G) bằng các phương pháp của Bộ Quốc phòng Hoa Kỳ, giảm nguy cơ hư hỏng và sửa chữa tốn kém khi thiết bị bị rơi hoặc va đập. Mỗi máy phân tích Vanta đều được xếp hạng IP55 để chịu được mưa, bụi bẩn. *

Có thể chịu được phạm vi nhiệt độ từ -10 ° C đến 50 ° C (14 ° F đến 122 ° F), máy phân tích Vanta đảm bảo bạn tối đa hóa thời gian hoạt động mà không mất thời gian chờ máy phân tích nguội, ngay cả trong môi trường nóng và điều kiện hoạt động ngoài trời. **

* Máy phân tích Dòng M được xếp hạng IP54.

** Với quạt tùy chọn. Hoạt động liên tục ở 33°C mà không cần quạt.

Đột phá

Máy phân tích XRF Vanta PMI cung cấp cho bạn kết quả chính xác giống nhau mọi lúc, từ lần thử nghiệm đầu tiên đến lần thử nghiệm thứ một trăm.

Công nghệ Axon™ độc quyền trên Vanta Series sử dụng thiết bị điện tử có độ nhiễu cực thấp cho phép đếm tia X trên mỗi giây cao hơn để có kết quả nhanh, chính xác và độ lặp lại cao.

Công nghệ Axon kết hợp với bộ vi xử lý lõi tứ mới làm cho máy phân tích Vanta phản hồi nhanh đáng kể, đẩy lùi các giới hạn về hiệu suất để bạn có được kết quả tốt nhất trong thời ngắn gian nhất. Công nghệ Axon cung cấp khả năng lặp lại thử nghiệm tốt nhất, vì vậy thử nghiệm đầu tiên cũng sẽ giống lần thử nghiệm cuối.

Công nghệ Axon cũng cung cấp giới hạn phát hiện cực thấp (LOD).

Năng suất

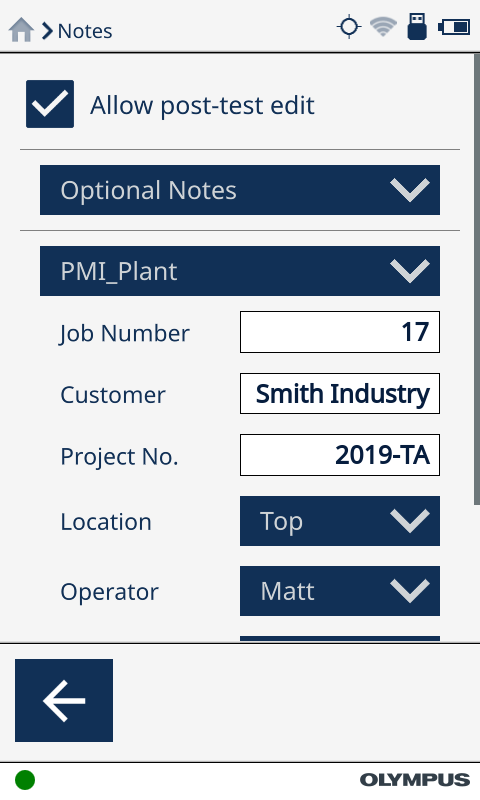

Để có năng suất cao hơn, người quản lý có thể tạo đăng nhập tên người dùng và mật khẩu cho mỗi người dùng.

Giao diện người dùng có thể tùy chỉnh để các bài kiểm tra và chức năng được sử dụng thường xuyên nhất xuất hiện trên màn hình chính. Thiết lập này dễ dàng được áp dụng cho toàn bộ nhóm của bạn, do đó bạn không mất thời gian thiết lập từng máy phân tích riêng lẻ.

Máy phân tích Vanta tối đa hóa thông lượng của người dùng và giúp lưu trữ dữ liệu dễ dàng. Các tính năng phần mềm dành riêng cho ứng dụng phân loại phế liệu cải thiện năng suất của người dùng để thu hồi vốn đầu tư nhanh chóng.

- Giao diện người dùng (UI) trực quan để điều hướng nhanh các cài đặt và chức năng phần mềm của thiết bị.

- Tùy chỉnh các tính năng và chức năng của phần mềm được hiển thị trên màn hình chính.

- Dễ dàng xuất dữ liệu qua ổ USB flash, mạng LAN không dây hoặc Bluetooth ® .

- Màn hình cảm ứng hiển thị rõ ràng, sáng sủa và có thể đọc được trong mọi điều kiện ánh sáng.

- Các nút công thái học và phím điều khiển nút bấm cấp công nghiệp giúp bạn dễ dàng điều hướng giao diện người dùng cả khi đeo đeo găng.

- Máy ảnh toàn cảnh 5 megapixel tùy chọn và một bộ chuẩn trực điểm nhỏ để phân tích chi tiết nhỏ.

Tính năng phần mềm

Các tính năng phục vụ cho phân loại phế liệu nhanh chóng và chính xác

Mang lại hiệu quả đầu tư nhanh chóng

Máy phân tích Vanta ™ để phân loại phế liệu có các tính năng phần mềm sáng tạo được tối ưu hóa cho việc phân loại phế liệu nhằm tối đa hóa các khả năng vốn đã nổi bật của dòng máy phân tích VANTA XRF.

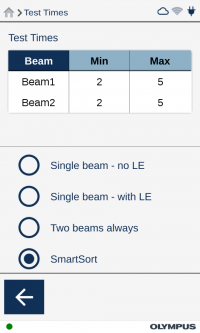

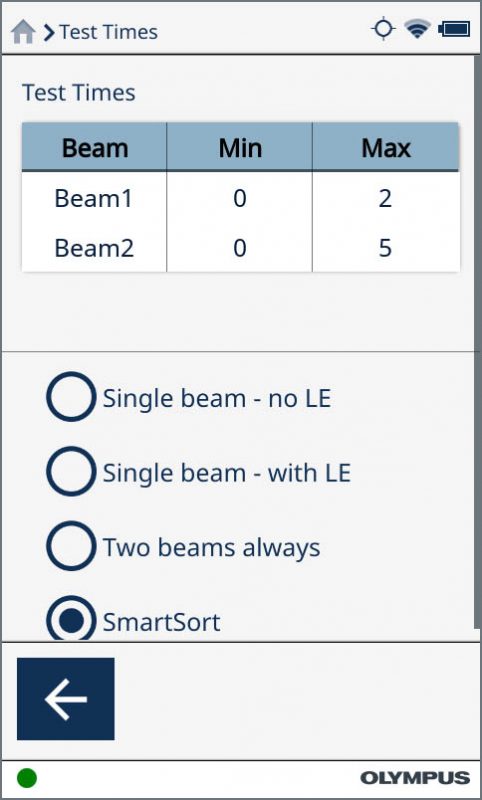

SmartSort tự động kéo dài hoặc rút ngắn thời gian kiểm tra để tiết kiệm thời gian và cung cấp độ phù hợp tốt nhất có thể cho các mác nhôm. Với SmartSort, cả nhân viên mới và nhân viên có kinh nghiệm đều nhanh chóng nhận được câu trả lời đúng như nhau:

Với bộ phân tích SmartSort, Vanta có thể:

- Cung cấp kết quả mác nhôm trong vòng 1 giây.

- Tự động kéo dài hoặc rút ngắn thời gian thử nghiệm dựa trên vật liệu để tiết kiệm thời gian.

- Biết khi nào cần mở rộng thử nghiệm để tìm nhôm trong kim loại màu hoặc hợp kim lớp niken.

Thông báo khớp mác hợp kim

Thống báo nhanh khớp mác hợp kim cung cấp hướng dẫn sắp xếp tin nhắn theo thời gian thực và / hoặc cửa sổ bật lên để đưa ra quyết định nhanh chóng.

- Thời gian thực và / hoặc thông báo nổi với tên thương mại hoặc cấp độ quen thuộc hoặc hướng dẫn xử lý đặc biệt.

- Tăng hiệu quả và thông lượng.

- Giảm đào tạo người dùng.

- Hợp lý hóa quy trình phân loại bằng cách giảm thiểu việc ra quyết định của người dùng.

So sánh mác hợp kim dễ dàng

So sánh các cấp gần nhau để biết hợp kim nào phù hợp nhất với giá trị danh nghĩa và giá trị thặng dư.

- Tự động xác định sự hiện diện của các nguyên tố không nhìn thấy được với XRF dựa trên thông số kỹ thuật của mác kim loại.

- Xác định sự hiện diện của các yếu tố gây ô nhiễm / tồn dư trong kim loại tái chế có thể ảnh hưởng đến giá trị của nó và / hoặc các yêu cầu xử lý từ nguồn.

- Đặt nồng độ dung nạp tối đa cho các nguyên tố còn lại trong các nhóm lớp.

- Gắn cờ các chất gây ô nhiễm cấp độ theo dõi mà không làm ảnh hưởng hoặc trì hoãn các kết quả phù hợp cấp độ nhanh, chính xác và kết luận.

Thiết lập thiết bị tùy chỉnh để quản lý nhóm

Mỗi máy phân tích Vanta dùng trong phân loại phế liệu đều có các tính năng phần mềm được thiết kế để cải thiện lợi tức đầu tư:

- Thu thập dữ liệu nhất quán trên nhóm thiết bị.

- Giao diện người dùng có thể tùy chỉnh cho các hoạt động phân loại nhiều bãi phế liệu và nhiều người dùng.

- Đăng nhập tên người dùng và mật khẩu duy nhất cho mỗi người dùng.

- Truyền thông số kỹ thuật và thiết lập thiết bị tùy chỉnh cho toàn bộ nhóm máy phân tích.

Gửi dữ liệu lên đám mây để có năng suất cao hơn

Máy phân tích Vanta giúp việc lưu trữ dữ liệu trở nên dễ dàng.

Phần mềm Vanta được tạo ra nhằm mục đích cải thiện năng suất của người dùng để phân loại nhanh và thu hồi vốn đầu tư:

- Giao diện phần mềm màn hình cảm ứng dễ sử dụng.

- Giao diện người dùng có thể định cấu hình .

- Cần điều khiển nút bấm để sử dụng với tay đeo găng.

- Máy ảnh tích hợp và một máy chuẩn trực điểm nhỏ để phân tích chi tiết nhỏ.