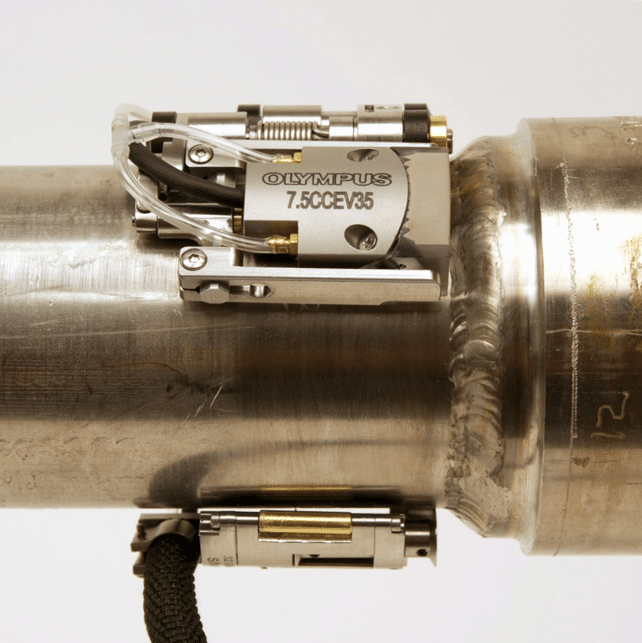

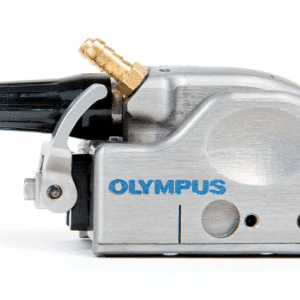

Với thiết kế mỏng, bộ quét siêu âm bán tự động này kiểm tra các đường ống trong các khu vực tiếp cận hạn chế, yêu cầu khe hở tối thiểu. Các chi tiết hạn chế khả năng tiếp cận, chẳng hạn như đường ống, giá đỡ và cấu trúc hỗ trợ cần có khoảng cách tối thiểu 12 mm (0,5 in.). Bộ quét có các lò xo được thiết kế để kẹp các ống thép cacbon và thép không gỉ có đường kính khác nhau bằng cách sử dụng nhiều mắt xích nhỏ. Tính năng độc đáo này cho phép máy quét được lắp và vận hành từ một phía của các hàng ống mà không cần thò tay hay sử dụng các dụng cụ từ phía đối diện. Bộ quét COBRA đặc trưng bởi chuyển động vòng ống mã hóa trơn tru, cho phép thu thập dữ liệu chính xác. Bộ quét chứa tối đa hai đầu dò PAUT hay TOFD để kiểm tra toàn bộ mối hàn trong một lần quét. Đối với việc kiểm tra đường ống dạng component-to-pipe hay các ống với mối hàn gần khúc elbow, bộ quét có thể được cấu hình để thực hiện kiểm tra từ một phía mối hàn bằng cách sử dụng một đầu dò duy nhất.

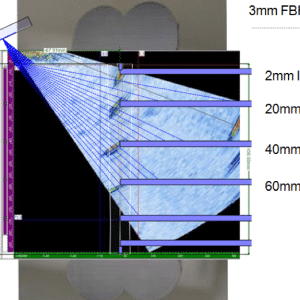

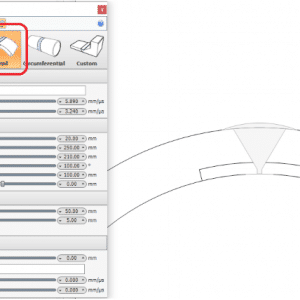

Giải pháp Olympus này sử dụng các đầu dò PAUT cấu hình thấp với khả năng lấy nét theo độ cao được tối ưu hóa, giúp tăng cường phát hiện các khuyết tật nhỏ trong đường ống thành mỏng. Các nêm cấu hình thấp được thiết kế đặc biệt phù hợp với từng đường kính ống có sẵn cho một giải pháp hoàn chỉnh. Bộ quét COBRA đảm bảo áp lực đầu dò ổn định, liên tục, do đó cung cấp tín hiệu UT chất lượng và mã hóa chính xác xung quanh toàn bộ chu vi của đường ống.

Giải pháp COBRA có thể được sử dụng với các đầu dò khác nhau, tùy thuộc vào ứng dụng. Kỹ thuật siêu âm mảng pha, mảng tuyến tính kép TRL và kỹ thuật siêu âm TOFD có thể được thực hiện bằng cách sử dụng các tùy chọn đầu dò sau:

Sử dụng các đầu dò PAUT cấu hình thấp với khả năng lấy nét theo độ cao được tối ưu hóa, giúp cải thiện việc phát hiện các khuyết tật nhỏ trong đường ống thành mỏng.

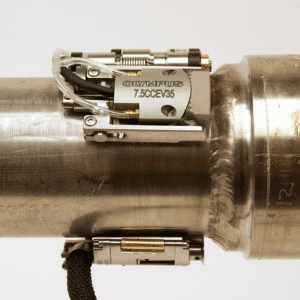

Bộ quét COBRA cũng có thể được cấu hình để kiểm tra mối hàn component-to-pipe.

Nêm kiểm tra TOFD phù hợp với bộ quét COBRA.

Dòng đầu dò mảng tuyến tính kép A25 (DLA) được thiết kế để kiểm tra vật liệu Austenit khi không thể kiểm tra bằng cách sử dụng đầu dò A15.

Tính năng nổi bật

- Sử dụng cho các đường ống từ 0.84 tới to 4.5 in. OD (21 mm tới 114 mm).

- Chiều cao tối thiểu chỉ cần 12 mm (0.5 in.) (trên các ống tiêu chuẩn), có thể hoạt động ở các vị trí tiếp cận hạn chế.

- Sử dụng cùng lúc 2 đầu dò giúp kiểm tra toàn bộ mối hàn trong một lần quét.

- Dễ dàng cài đặt và điều chỉnh từ một phía, không cần dụng cụ luồn sau các ống.

- Có thể cấu hình để kiểm tra mối hàn tiếp cận một phía.

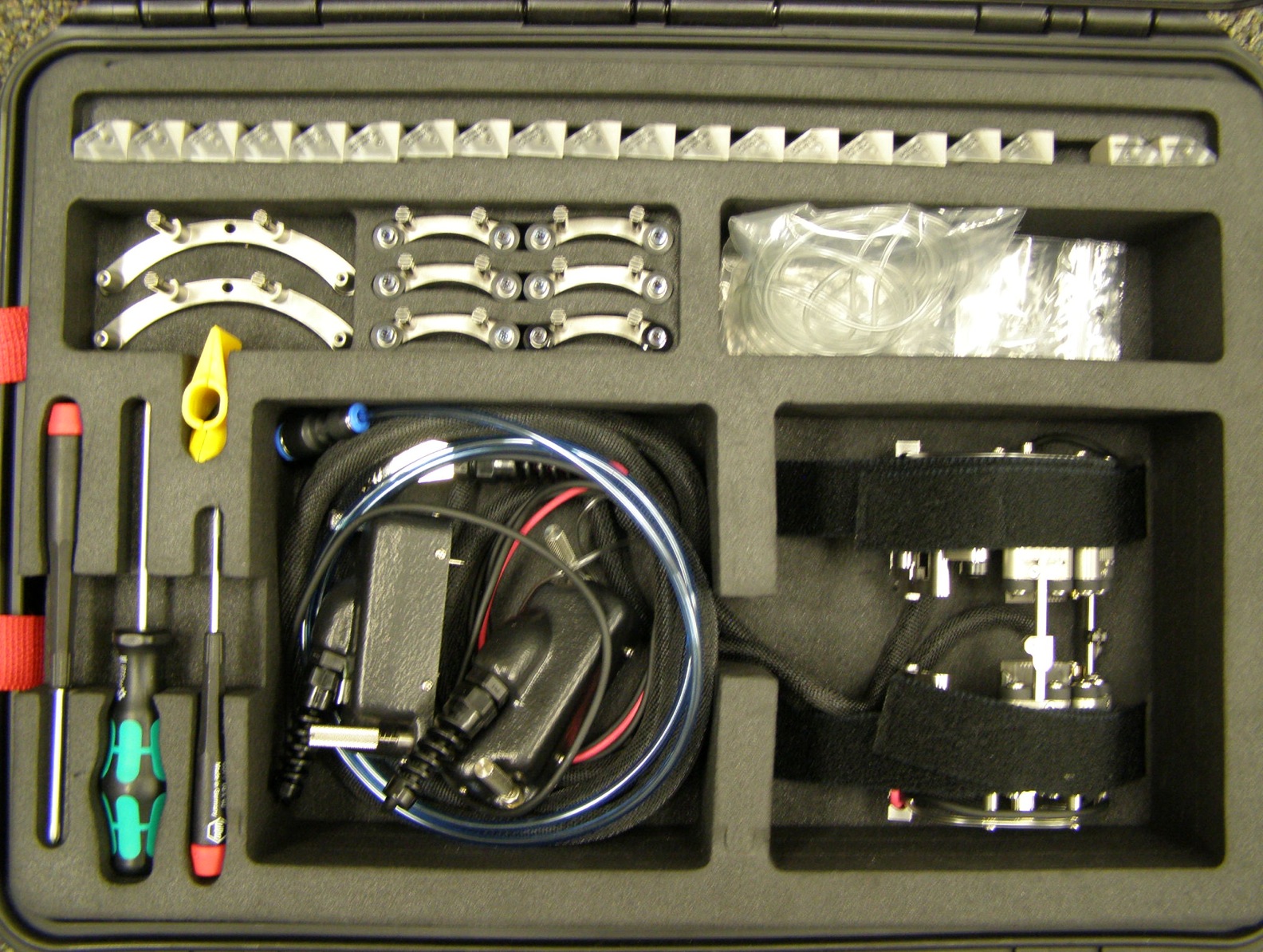

- Các mẫu template có sẵn giúp cho việc lắp đặt theo nhiều đường kính ống khác nhau trở nên dễ dàng.

- Thiết bị giúp đầu dò ổn định, áp lực đều khi di chuyển quanh chu vi ống.

- Bánh xe cao su giúp chuyển động êm ái và tránh bị xê dịch.

- Độ phân giải bộ quét lên tới 32 steps/mm.

- Gọn, nhẹ, cơ động.

- Đầu dò và nêm có thể đễ dàng thay đổi.

- Khoảng cách giữa hai đầu dò có thể cấu hình từ 0 mm tới 55 mm.

- Cơ chế lò xo giúp hoạt động trên cả ống thép không gỉ và thép thường.

- Chống gỉ và chịu nước.

Câu hỏi thường gặp khi sử dụng bộ quét COBRA (FAQ)

1. Độ dày nhỏ nhất có thể kiểm tra được với đầu dò COBRA trên các ống đường kính nhỏ?

Không thể đưa ra được con số chính xác cho chiều dày thành ống nhỏ nhất có thể kiểm tra được. Tham số này liên quan tới loại khuyết tật, vật liệu, nhiễu âm trong vật liệu và kỹ năng của người vận hành thiết bị. Bản thân khách hàng sẽ là người cần thực hiện các kiểm tra thử nghiệm và đưa ra kết luận. Các ống đường kính nhỏ cũng thường làm suy giảm tín hiệu khá nhiều khi phản xạ trên các bề mặt cong và các ống mỏng có thể cần thực hiện kiểm tra với nhiều lần quét khác nhau. Các kết hợp của nhiều yếu tố ở trên có thể gây ra các khó khăn khi kiểm tra ống nhỏ và mỏng.

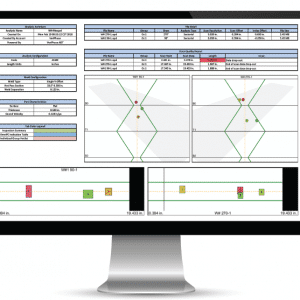

2. Bộ quét siêu âm COBRA có tương thích với các code về AUT không?

Tất nhiên là “Có”! Bộ quét và thiết bị là một phần quan trọng của quy trình hay trình tự kiểm tra, được viết để tuân thủ theo tiêu chuẩn hay code. Các thông tin có thể bao gồm tốc độ quét, khả năng mã hóa vị trí, độ tuyến tính của thiết bị, tùy chọn phần mềm và phiên bản, khả năng lưu trữ dữ liệu của thiết bị làm nên một phần của quá trình kiểm tra.

COBRA giúp đạt và tuân thủ các tiêu chuẩn kiểm tra sau:

- ASME CC 2235

- ASME B31.3 CC 181

- ASME B31.1 CC 179

3. COBRA có thể sử dụng để kiểm tra các mối hàn với ống elbow hay mối hàn component-to-pipe không?

Có, nếu phần ống thẳng ở mỗi bên mối hàn đủ khoảng cách, có thể thực hiện kiểm tra sử dụng hai đầu dò hai bên. Nếu không, bộ quét COBRA có thể cấu hình để thực hiện kiểm tra từ một phía của mối hàn.

4. Chiều dài phần ống thẳng ở mỗi bên của mối hàn cần có khi thực hiện kiểm tra với COBRA?

Cần tối thiệu 59 mm ống phẳng để đặt được bộ quét COBRA. Với các mối hàn, có thể phải tính toán thêm nửa chiều rộng mối hàn tính từ tâm, khi đó khoảng cách tối thiểu sẽ là 59 mm + một nửa chiều rộng mối hàn.

Mã đặt hàng phụ kiện COBRA

| U8907974 | COBRA-SP-ENC | Encoder Replacement for Cobra Scanner |

| U8775226 | Cobra-SP-Irrigation | Irrigation Kit for Cobra Scanner |

| U8908979 | Cobra-SP-YokeArm | Pair of yoke arms with screws for one yoke of the Cobra scanner. |

| U8907386 | 60BA0060 | Cobra cable sheathing -Autoclosing Sheath 3/8@5/8 – by the foot |

| U8909471 | 25CC0564 | Spring Cobra (LEFT probe holder assembly) |

| U8909470 | 25CC0563 | Spring Cobra (RIGHT probe holder assembly) |

| U8909468 | 25AA2123 | DGS017-R Probe holder left |

| U8909469 | 25AA2124 | DGS017-L Probe holder right |

| U8909466 | 25AA2125 | DGS003-LTail link assy (without encoder) |

| U8909467 | 25AA2108 | DGS003-R Tail link assy (with encoder) |

| OmniScan Common Accessories | ||

| U8760010 | OMNI-A-BATT | OmniScan battery pack |

| U8764053 | OMNI-A-SHCASE | Small black hard carrying case (19-1/8 in. x 15-7/16 in. x 7-9/16 in. / 48.6 cm x 39.2 cm x 19.2 cm) |

| U8767093 | OMNI-A-AC | OmniScan AC adapter |

| U8775201 | OMNI-A2-ADP20 | Scanner interface adaptor to connect scanners encoder cables with DE15 connector to OmniScan MX2 with Lemo connector scanner interface. |

| U8780306 | OMNI-A2-SDCard | SDHC Card for OmniScan MX2 |

| U8780305 | OMNI-A2-ScreenProtec | Kit of 5 anti-glare touch screen protectors for OmniScan MX2 |

| U8780307 | OMNI-A2-USBDrive | Mini USB drive for OmniScan MX2 |

| U8780317 | OMNI-A2-STYLUS | 5 Stylus kit for touchscreen use |

| U8767077 | OMNI-A-CHRG | External battery charger |

| Common Probe and Wedge Parts | ||

| U8330826 | 7.5CCEV35-16-8X10-A15-P-2.5-OM | Standard Phased Array Probe, 7.5 MHz Concave Elevation Focused Array 35 mm Radius, 16 Elements, 8×10 mm Total Active Aperture, 0.50 mm Pitch, 10 mm Elevation, A15 Case Type, Impedance Matching to Rexolite, PVC Sheathing, 2.5 m Cable Length, Omiscan Connector |

| U8331014 | 10CCEV35-32-8X7-A15-P-2.5-OM | Standard Phased Array Probe, 10 MHz Concave Elevation Focus 35 mm Radius, 32 Elements, 8×7 mm Total Active Aperture, 0.25 mm Pitch, 7 mm Elevation, A15 Case Type, Impedance Matched to Rexolite, PVC Sheathing, 2.5 m Cable Length, OmniScan Connector |

| U8331163 | 5CCEV35-16-8X10-A15-P-2.5-OM | Standard Phased Array Probe, 5.0 MHz Concave Elevation Focused Array 35 mm Radius, 16 Elements, 8×10 mm Total Active Aperture, 0.50 mm Pitch, 10 mm Elevation, A15 Case Type, Impedance Matching To Rexolite, PVC Sheathing, 2.5 m Cable Length, OmniScan Connector |

| U8331117 | 2.25CCEV35-16-8X10-A15C-P-2.5-OM | Custom Phased Array Probe, 2.25 MHz Concave Elevation Focused Array, 35 mm Radius, 16 Elements, 8×10 mm Total Active Aperture, 0.50 mm Pitch, 10 mm Elevation, Custom A15 Case Type, Impedance Matching To Rexolite, PVC Sheathing, 2.5 m Cable Length, OmniScan Connector |

| U8779635 | SCREWKIT-1-64-CAPTIVE-CUSTOM | Kit of (16x) SCRW-10010, Screw 1-64 Captive Custom Screws for A15 Case Style |

Mã đặt hàng đầu dò A15

| Part Number | Item Number | Freq. (MHz) | Number of Elements | Pitch (mm) | Elevation (mm) | Elevation Curvature Radius (mm) |

| 2.25CCEV35-A15C-P-2.5-OM* | U8331117 | 2.5 | 16 | 0.5 | 10 | 35 |

| 3.5CCEV35-A15C-P-2.5-OM* | U8331149 | 3.5 | 16 | 0.5 | 10 | 35 |

| 5CCEV35-A15-P-2.5-OM | U8331163 | 5.0 | 16 | 0.5 | 10 | 35 |

| 7.5CCEV35-A15-P-2.5-OM | U8330826 | 7.5 | 16 | 0.5 | 10 | 35 |

| 10CCEV35-A15-P-2.5-OM | U8331014 | 10.0 | 32 | 0.3 | 7 | 35 |

These probes come standard with an OmniScan® connector and a 2.5 m (8.2 ft) cable.

* A15C casing are based on the same design as the A15 but are 2 mm taller, increasing height clearance.

Mã đặt hàng đầu dò A25

| Q3301132 | 5DL16-12X5-A25-P-2.5-OM | Standard Phased Array Probe, 5 MHz, Dual 16 Element Arrays, 12×5 mm Total Active Aperture, 0.75 mm Pitch, 5 mm Elevation, A25 Case Type, Impedance Matching to Rexolite, PVC Sheathing, 2.5 m Cable Length, 1X Omniscan Connector. |

| Nêm đầu dò A25/Wedges | ||

| Q7201159 | SA25-DN70L-Kit | One (1) SA25-DN70L flat wedge plus nine (9) SA25-DN70L curved wedges to cover nominal pipe sizes (NPS) with outside diameters ranging from 0.84in to 4.5in. Features IH option (Irrigation and scanner Holes). To fit A25 Dual array probes. IMPORTANT NOTE: Focal laws for OmniScan using this solution cannot be created in the OmniScan. NDT SetupBuilder is required to create focal laws for the OmniScan. Tomoview can also be used. This solution will increase minimum height clearance required for use of the Cobra scanner. |

| Q7201141 | SA25-DN70L3.8-IH | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 3.8° Roof Angle, with IH option (Irrigation and Holes). |

| Q7201150 | SA25-DN70L11-IH-AOD1.05 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 11° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 0.84 in. (21.34 mm) to 1.05 in. (26.67 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201149 | SA25-DN70L10-IH-AOD1.315 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 10° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 1.05 in. (26.67 mm) to 1.315 in. (33.4 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201148 | SA25-DN70L8.5-IH-AOD1.66 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 8.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 1.315 in. (33.4 mm) to 1.66 in. (42.16 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201142 | SA25-DN70L8-IH-AOD1.9 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 8° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 1.66 in. (42.16 mm) to 1.9 inches (48.26 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201147 | SA25-DN70L7.5-IH-AOD2.375 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 7.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 1.9 in. (48.26 mm) to 2.375 in. (60.33 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201146 | SA25-DN70L6.5-IH-AOD2.875 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 6.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 2.375 in. (60.33 mm) to 2.875 in. (73.03 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201145 | SA25-DN70L6-IH-AOD3.5 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 6° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 2.875 in. (73.0 3 mm) to 3.5 in. (88.9 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201144 | SA25-DN70L5.5-IH-AOD4 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 5.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 3.5 in. (88.9 mm) to 4 in. (101.6 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201143 | SA25-DN70L5.5-IH-AOD4.5 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 5.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 4 in. (101.6 mm) to 4.5 in. (114.3 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Phụ kiện thay thế/Spare Parts | ||

| Q3301131 | SCREW KIT, 1-64 X 1/8″ CAPTIVE CUSTOM | Kit of (16x) Screw 1-64 x 1/8” Captive Custom, for A25 Case Style |