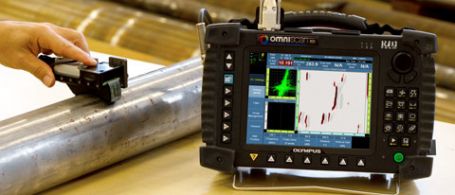

Stress Corrosion Cracking Solutions

Olympus offers a range of productive solutions to detect or evaluate the depth of surface-breaking stress corrosion cracking. These solutions are based on the OmniScan MX ECA, a powerful and easy to use eddy current array flaw detector.View Product

Doubler Edge Skin Crack Inspection Solution

The Doubler Edge Skin Crack Inspection solution utilizes the latest ECA technologies for subsurface detection. The C-scan allows for higher probability of detection and better reproducibility. This solution is a major step forward in terms of reduced inspection time.View Product

ECA Surface Crack Detection

The Surface Crack ECA solution proposes an ergonomically-improved version of the SBBR-026 high-resolution ECA probe. This solution detects surface-breaking cracks at a very productive rate, even through paint and thin coatings. This is particularly well-suited for performing fast inspections of aircraft fastener rows.View Product

ECA Subsurface Crack Detection

The Subsurface Crack ECA inspection solution is capable of scanning through the first aircraft layer (skin) to detect cracking present on the 2nd layer, without the need for paint removal. This solution is available in two ECA probe versions (commercial and military aircrafts), both covering at least 64 mm in a single pass.View Product

ECA Subsurface Corrosion Detection

The Subsurface Corrosion ECA inspection solution performs rapid inspection of large areas for potential corrosion. Available in two probe versions (commercial and military aircrafts), this solution can evaluate the severity of hidden corrosion (defect depth) in an instant, without the need for paint removal.View Product

새로운

Carbon Steel Surface Examination

The MagnaFORM™ eddy current array solution enables users to inspect through paint and rough surfaces. The dynamic lift-off compensation helps ensure that the sensitivity to surface-breaking defects is maintained on the roughest of welds and corroded areas.View Product