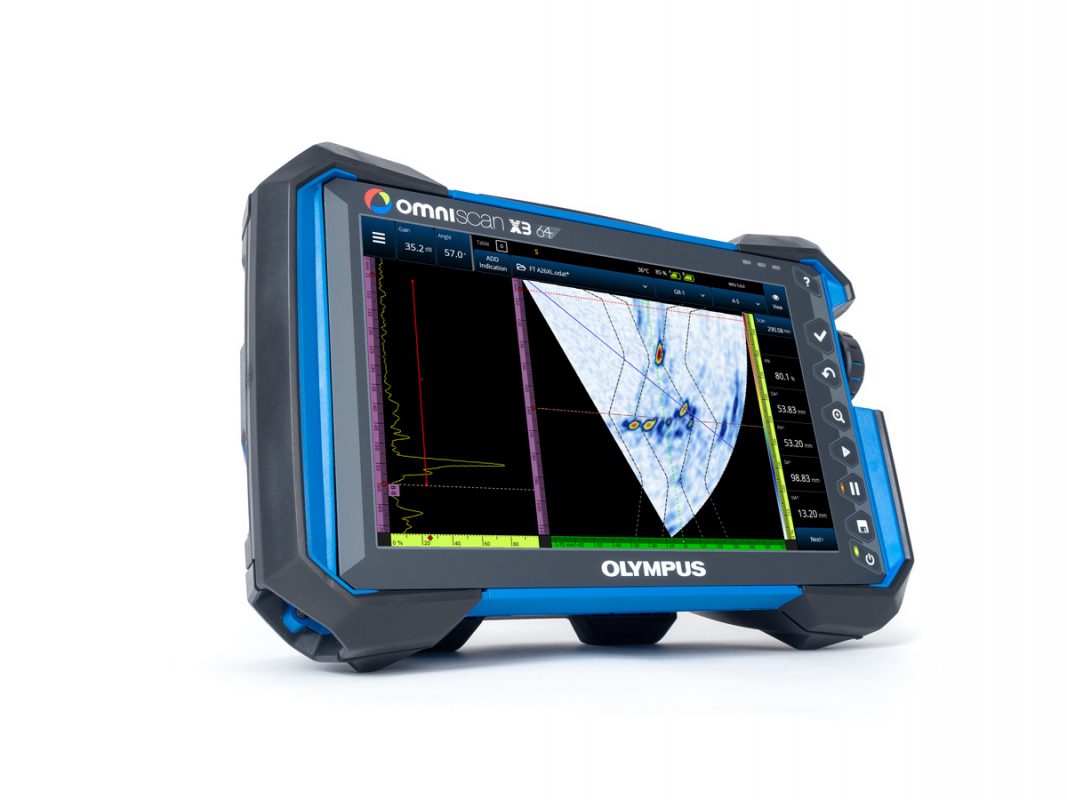

OmniScan™ X3 64 Phased Array and TFM

Stronger – more confident

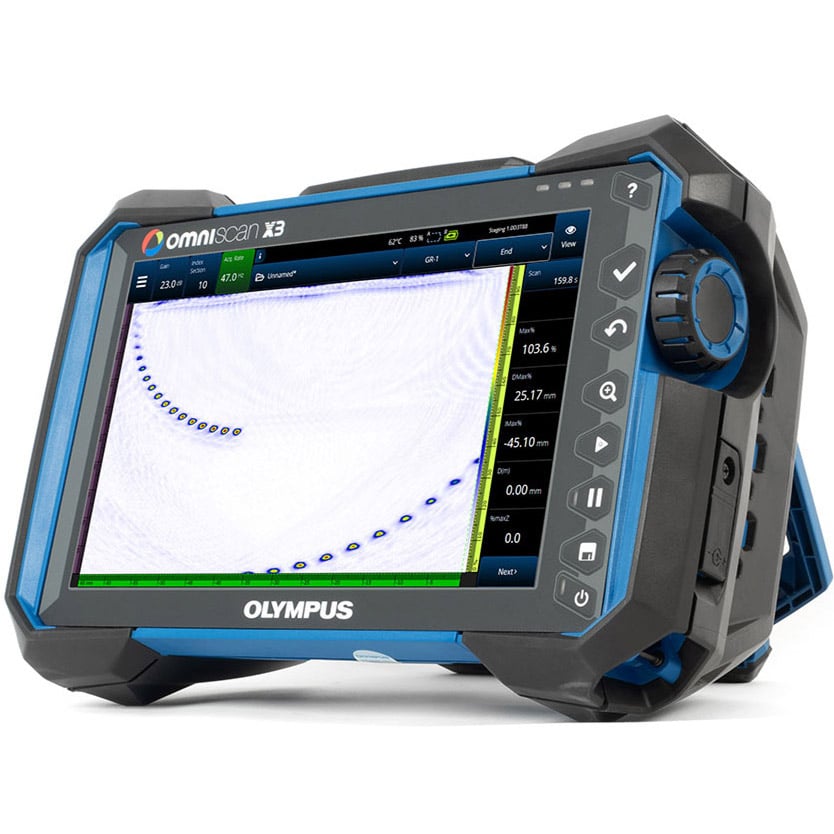

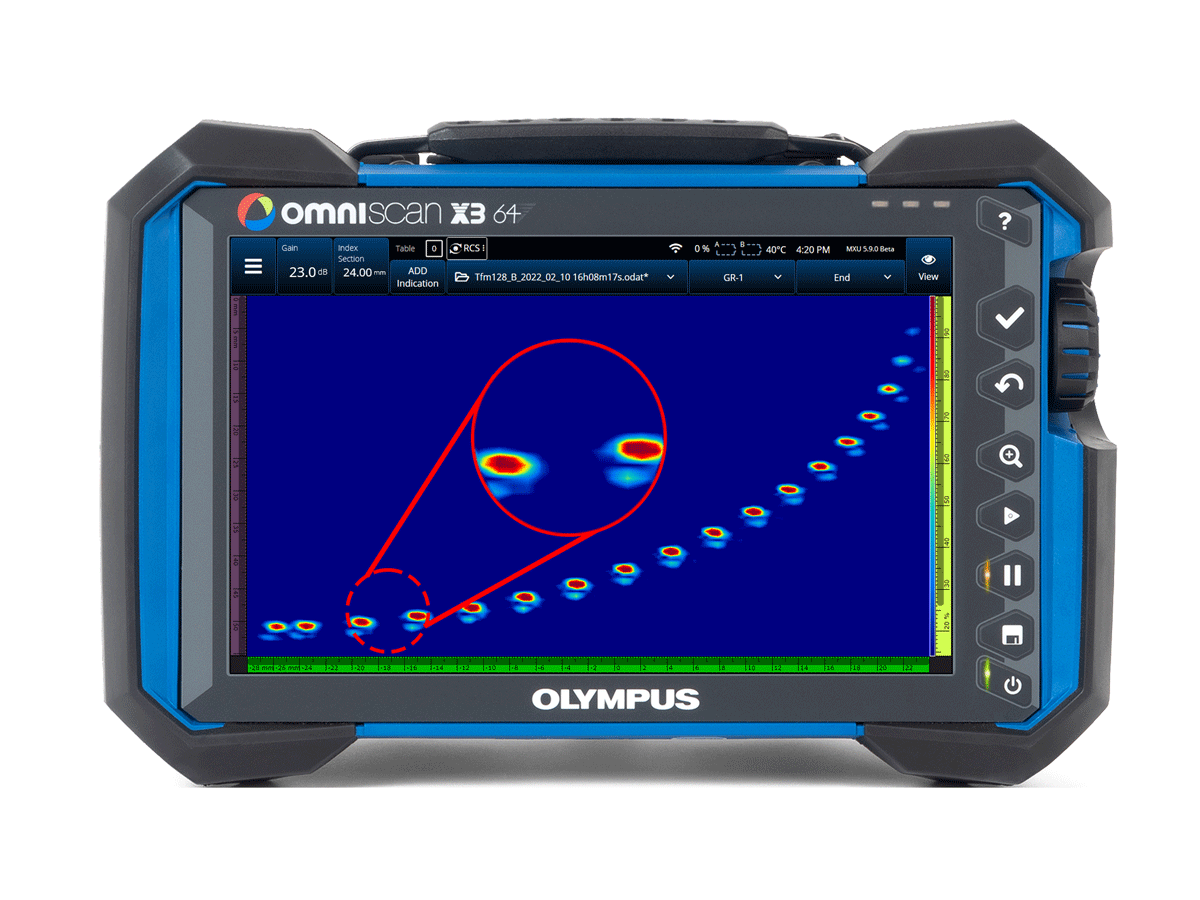

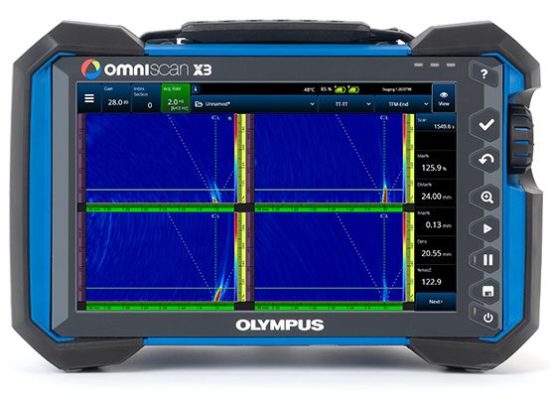

Placed in the shell OmniScan X3 Rugged and maneuverable, the powerful focus rendering of the OmniScan X3 64 is enhanced with a larger variable aperture allowing you to fully exploit the probes Phased Array 64 elements and TFM 128 elements. Using the instrument's enhanced performance helps meet the challenges of testing thick and high-attenuation materials, expanding the potential through developing new processes for more applications.

Download Catalog X3 Download Catalog X3 64Clearer – more confident

The OmniScan X3 defect ultrasound device is packed with powerful tools such as the full-image focus matrix method (TFM) and enhanced data processing and visibility, allowing you to complete inspections with greater confidence.

WeldSight™ softwareInnovative and efficient TFM

Confirm TFM zone signal immediately upon installation

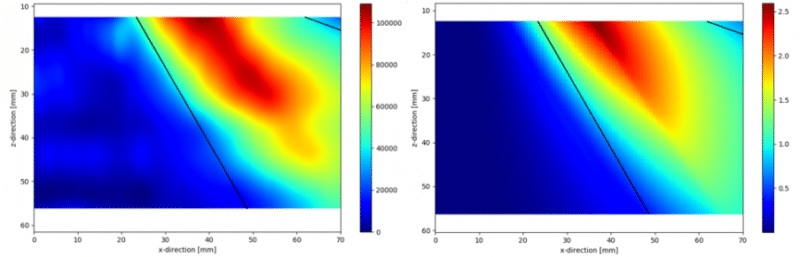

Tools Sound pressure influence map (AIM) gives you a visual model of the sensitivity according to your TFM modes, transducers, settings.

The AIM engine eliminates the guesswork when Schedule a scan — instantly visualize wave set impact (TFM mode), see where the sensitivity ends, and adjust your scan plan accordingly.

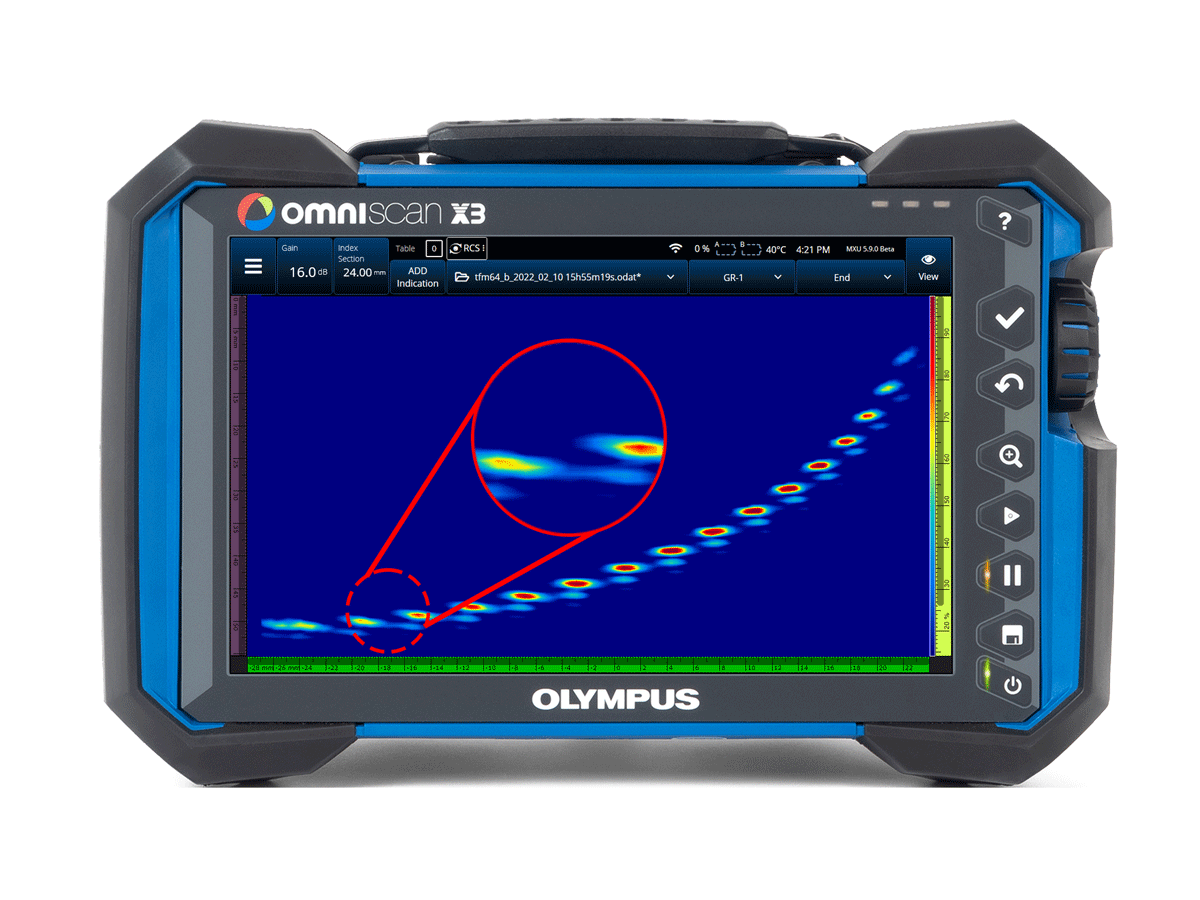

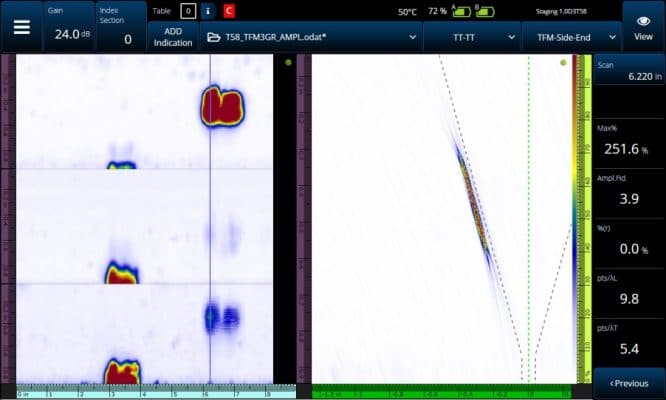

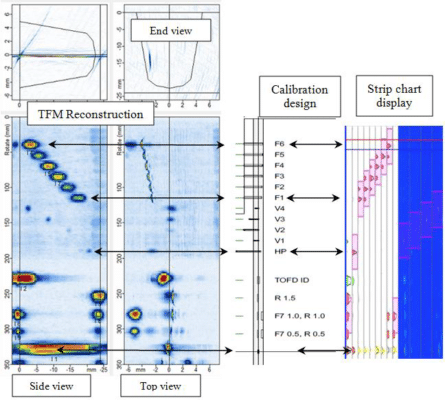

4 TFM modes simultaneously

Facilitating defect assessment and sizing

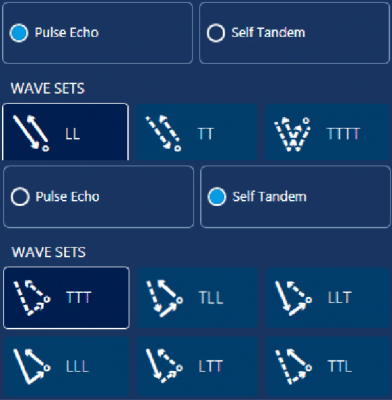

Using different TFM modes (wave sets) in the same test screen increases chance of discovery indications have an abnormal direction. OmniScan X3 provides up to four simultaneous TFM modes to produce images from different angles.

Signal response and characteristics from each mode — such as diffraction from defect peaks, corner trap effects, and defect profiles can be used simultaneously for validation defect type and improve sizing ability.

WeldSight software supports merging data from 4 groups of TFMs or from many different data files, making interpretation and sizing in TFM easier and faster than ever.

Find lost data via PCI

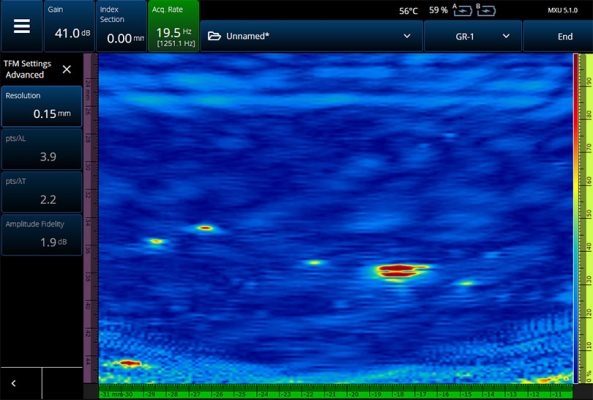

Phase coherence imaging – technique independent of response signal amplitude

Breakthrough phase-coherence imaging technique enhances sensitivity for detection of minor defects and penetration with noisy materials, while requiring no complicated installation steps and for key evaluation and sizing more precise. Available on OmniScan X3 64 version and MXU 5.10 software.

Ưu điểm của PCI

Collaborate online, anytime, anywhere

Remote collaboration on X3 (X3 RCS) allows you to share your screen with other members and can control devices remotely and hold video conferences with participants anywhere have Internet.

Improved Calibration speed

Calibration for the OmniScan X3 performs high-speed capture of signals, completing multi-group calibrations in minutes.

Familiar experience

If you're an OmniScan user, everything will be familiar. If you are new to phased array ultrasound or TFM, the OmniScan X3 is a device that is very easy to master.

User manual X3 RCSGiàu chi tiết hơn

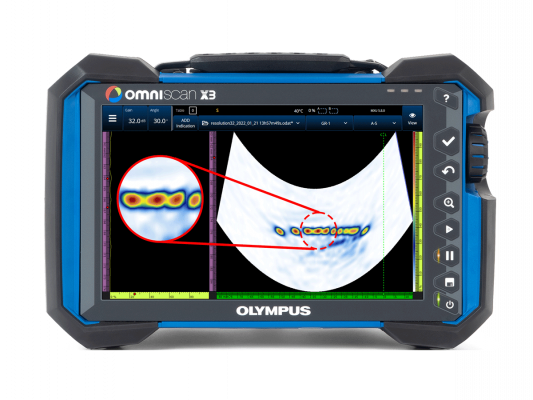

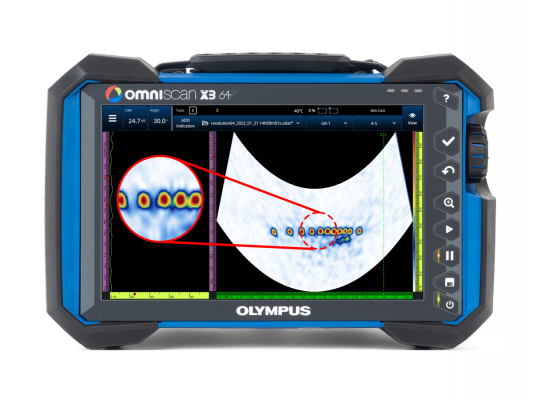

PAUT 64 elements

Harness the full potential of the 64-element array probe using the OmniScan X3 64 ultrasound machine, delivering improved resolution and a wider focus area.

TFM 128 elements

TFM images focus better when checking for smaller defects, and the signal-to-noise ratio (SNR) is improved. With an aperture of up to 128 elements, combined with the OmniScan X3 64 provides clearer images and faster speeds.

Build TFM 4 times faster

Achieve up to 4x faster overall focusing method (TFM) acquisition when using the 64-element probe. Compared to machines with 32 pulsers, the OmniScan X3 64 offers a significant improvement in efficiency thanks to its larger aperture.

Improved Phased Array

- 3 times faster than OmniScan MX2 (maximum pulse repetition frequency).

- Independent TOFD menu for faster calibration process.

- High amplitude range up to 800% reduces the need for rescan.

- Probe support Dual Linear Array™ and Dual Matrix Array™ integrations to speed up the setup process.

Corrosion mapping settings

Use PAUT to Corrosion test offers many benefits such as excellent coverage and resolution. OmniScan X3 combines advanced functions such as port synchronization with thoughtfully designed software and simplified menus, so you can more easily obtain more accurate corrosion data. Configure setup quickly thanks to automatic A-scan synchronization processing and manual sensitivity correction (TCG).

Dòng sản phẩm OmniScan X3

| Device | OmniScan X3 | OmniScan X3 64 | ||

| Configuration | 16:64PR | 16:128PR | 32:128PR | 64:128PR |

| Applications | Corrosion monitoring, pipeline integrity, manual PA/TFM, TOFD, Small pipeline. | Multi-group thin weld combined PA & TOFD, Manufacture of wind turbine blades, Composite. | Multi-Group Thickness Weld combines PA & TOFD, Austenitic / CRA / Multi-Material Weld, TFM. | High Performance Multi-Group Very Thick Weld PA & TOFD, Austenitic / CRA / Multi-Material Weld, High Yield TFM, High Temperature Hydrogen Attack (HTHA), Advanced Application Development. |

| Transmitter (PA) | 16 | 16 | 32 | 64 |

| Receiver | 64 | 128 | 128 | 128 |

| TFM . variable | 32 | 32 | 64 | 128 |

| UT Channel (P/R) | 2 | 2 | 2 | 2 |

| Multi-group | Up to 2 (PA, UT/TOFD, TFM) or 2 PA with 1 TOFD |

Up to 8

TFM up to 4 |

Up to 8

TFM up to 4 |

Up to 8

TFM up to 4 |

| Frequency Bandwidth | 0.5 to 18 MHz | 0.2 MHz to 26.5 MHz | ||

| Maximum Pulse Width (PA) | 500 ns | 1000 ns | ||

| Voltage PA | 40 V, 80 V and 115 V / Monopole negative | 10 V, 20 V, 40 V, 80 V, 120 V and 160 V / Bipolar square pulse | ||

| SSD Storage Capacity | 64 GB | 1 TB | ||

| All other features and specifications | Same | |||

Optional accessories

| U8760010 | OMNI-A-BATT | Extra and replacement batteries for OmniScan. |

| U8767093 | OMNI-A-AC | The AC Adapter is used to charge the OmniScan. |

| U8767077 | OMNI-A-CHRG | Charge the OmniScan battery (External Charger). |

| U8100133 | OMNI-A2-SPLIT128 | “Y” adapter (splitter) with OmniScan connectors to support 2 phased array probes with a maximum of 64 elements each on a 128 channels OmniScan MX2 instrument with PA2 module. |

| U8100134 | OMNI-A2-SPLIT128-4UT | “Y” adapter (splitter) with OmniScan connectors to support 2 phased array probes with a maximum of 62 elements each and 4 UT channels with Lemo-00 connectors on a 128 channels OmniScan MX2 instrument with PA2 module. UT channels are connected to elements: 63, 64, 127, 128 |

| U8100135 | OMNI-A2-SPLIT64 | “Y” adapter (splitter) with OmniScan connectors to support 2 phased array probes with a maximum of 32 elements each on a 64 channels OmniScan MX2 instrument with PA2 module. |

| U8100136 | OMNI-A2-SPLIT64-4UT | “Y” adapter (splitter) with OmniScan connectors to support 2 phased array probes with a maximum of 30 elements each and 4 UT channels with Lemo-00 connectors on a 64 channels OmniScan MX2 instrument with PA2 module. UT channels are connected to elements: 31, 32, 63, 64 |

Specifications

Các thông số chung cho cả OmniScan X3 và OmniScan X3 64.

|

Type |

Multigroup, multimode ultrasonic flaw detector |

|

Size (W × H × D) |

335 mm x 221 mm x 151 mm (13.2 in. x 8.7 in. x 5.9 in.) |

|

Weight |

5.7 kg (12.6 lb) (with 1 battery) |

|

Hard Drive Capacity |

OmniScan X3 : Internal 64 GB SSD |

|

Storage Devices |

SDHC™ and SDXC™ cards or most standard USB storage devices |

|

Max Onboard File Size |

25 GB |

|

GPS |

Yes (unless specified otherwise for some regions) |

|

Alarms |

3 |

|

Wireless Connection |

Yes – wireless LAN dongle included in the package (model varies according to region) |

|

PA Connectors |

1 connector |

|

UT Connectors |

4 (2 channels P/R) |

|

Certifications |

ISO 18563-1:2015 |

|

display |

|

|

Type |

TFT LCD with resistive touch screen |

|

Size |

269 mm (10.6 in.) |

|

Resolution |

1280 × 768 pixels |

|

Number of Colors |

16 million |

|

Viewing Angles |

Horizontal: −85° to 85° |

|

I/O Ports |

|

|

USB 2.0 |

2 ports (one hidden behind the battery) |

|

USB 3.0 |

1 port |

|

Video Output |

Video out (HDMI) |

|

Memory Card |

SDHC port |

|

Communication |

Ethernet |

|

I/O Lines |

|

|

Encoder |

2-axis encoder line (quadrature quadrature direction), 3rd encoder ready |

|

Digital Input |

6 digital inputs, TTL |

|

Digital Output |

5 digital outputs, TTL |

|

Acquisition On/Off Switch |

Through the configuration of a digital input |

|

Power Output Line |

5 V nominal, 1 A (short-circuit protected), and 12 V output at 1 A |

|

External DC Supply |

|

|

DC-IN Voltage |

15 VDC to 18 VDC (min. 50 W) |

|

Connector |

Circular, 2.5 mm pin diameter, center-positive |

|

Battery |

|

|

Type |

Lithium-ion battery |

|

Capacity |

87 Wh |

|

Number of Batteries |

2 |

|

Life |

5 hours using 2 batteries (hot-swap capable) |

|

PA/UT Configuration |

|

|

Bit Depth |

16 bits |

|

Maximum PRF |

20 kHz |

|

Frequency |

|

|

Effective Digitizing Frequency |

Up to 100 MHz |

|

display |

|

|

Refresh Rate |

A-scan: 60 Hz; S-scan: 20 Hz to 30 Hz |

|

Envelope (echo-dynamic mode) |

Yes: Volume-corrected S-scan (30 Hz) |

|

A-Scan Height |

Up to 800% |

|

Synchronization |

|

|

On Internal Clock |

1 Hz to 10 kHz |

|

External Pace |

Yes |

|

On Encoder |

On 2 axes: from 1 to 65,536 steps |

Xử lý dữ liệu

|

Maximum Number of A-Scan Data Points |

Up to 16,384 |

|

Real-Time Averaging |

PA: 2, 4, 8, 16 |

|

Rectification |

RF, full wave, half wave+, half wave- |

|

Filtering |

PA channel (OmniScan X3): 8 low-pass, 6 band-pass, and 4 high-pass filters |

|

Video Filtering |

Smoothing (adjusted to the probe frequency range) |

|

Programmable TCG |

|

|

Number of Points |

32: One TCG (time-corrected gain) curve per focal law |

|

Range |

PA (standard): 40 dB per step of 0.1 dB |

|

Maximum Slope |

PA (standard): 40 dB/10 ns |

Acoustic Specifications

|

Model |

OmniScan X3 |

OmniScan X3 64 |

Both |

|

Pulser |

PA Channel |

PA Channel |

UT Channels |

|

Voltage |

40 V, 80 V, and 115 V |

10 Vpp, 20 Vpp, 40 Vpp, 80 Vpp, 120 Vpp, and 160 Vpp |

85 V, 155 V, and 295 V |

|

Pulse Width |

Adjustable from 30 ns to 500 ns; resolution of 2.5 ns |

Adjustable from 30 ns to 1000 ns (half period of bipolar pulse or duration of negative of pulse); resolution of 5 ns |

Adjustable from 30 ns to 1,000 ns; resolution of 2.5 ns |

|

Fall Time |

< 10 ns |

< 10 ns |

< 10 ns |

|

Pulse Shape |

Negative square pulse |

Bipolar negative-positive square pulse Negative square pulse |

|

|

Output Impedance |

28 Ω in pulse-echo |

35 Ω |

< 30 Ω |

|

Receiver |

PA Channel |

UT Channels |

|

|

Gain Range |

0 dB to 80 dB maximum input signal; 550 mVp-p (full-screen height). |

0 dB to 80 dB; maximum input signal 900 mVp-p (full-screen height). |

0 dB to 120 dB maximum input signal; 34.5 Vp-p (full-screen height). |

|

Input Impedance |

57 Ω ± 10% at 9 MHz in pulse-echo |

120 Ω ±10 % at 13 MHz |

50 Ω in pulse-echo mode |

|

System Bandwith |

0.5 MHz to 18 MHz |

0.2 MHz to 26.5 MHz |

0.25 MHz to 28 MHz |

|

Beam Formation |

PA Channel |

UT Channels |

|

|

Scan Type |

Single, linear, sectorial, compound, and TFM |

– |

|

|

Maximum Aperture |

OMNIX3-PATFM1664PR = 16 elements |

OMNIX3-PATFM64128PR = 64 elements |

– |

|

Number of Receiving Elements |

OMNIX3-PATFM1664PR = 64 receiving elements |

OMNIX3-PATFM64128PR =128 elements |

– |

|

Number of Focal Laws |

Up to 1024 |

– |

|

|

Delay Range Transmission |

0 µs to 10 µs in 2.5 ns increments |

0 µs to 10 µs in 5 ns increments |

– |

|

Delay Range Reception |

0 µs to 6.4 µs in 2.5 ns increments |

– |

|

TFM/FMC

|

Supported Modes |

Pulse-echo: L-L, T-T, and TT-TT |

|

Number of Groups |

Up to 4 simultaneous TFM groups |

|

Maximum Aperture |

64-element aperture for 64:128PR |

|

Image Resolution |

Up to 1024 × 1024 (1 M points) for each TFM group |

|

Live TFM Envelope |

Yes |

Môi trường hoạt động

|

Ingress Protection Rating |

IP65 certified (completely protected against dust and water jets from all directions (6.3 mm nozzle)) |

|

Shockproof Rating |

Drop tested according to MIL-STD-810G |

|

Intended Use |

Indoor and outdoor use |

|

Altitude |

Up to 2,000 m (6,561 ft) |

|

Operating Temperature |

−10 °C to 45 °C (14 °F to 113 °F) |

|

Storage Temperature |

−20 °C to 60 °C (−4 °F to 140 °F) (with battery inside) |

Professional NDT process

MXU

The familiar software on the X3 guides each step of the test through the question-and-answer.

OmniPC 5

The free OmniPC PC analysis tool is compatible with data files from OmniScan X3, OmniScan MX2 and OmniScan SX.

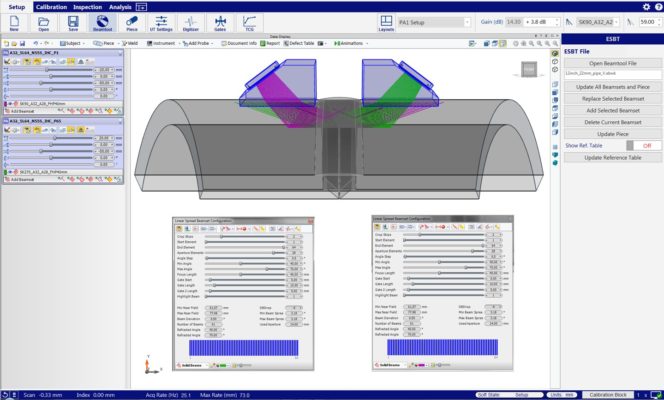

WeldSight

Advanced acquisition, processing, and analysis with dedicated WeldSight software for OmniScan X3. For increased productivity, WeldSight Remote Connect software connects directly to and controls the OmniScan X3 from a PC.

Have everything 9 file, size 59.8 MiB with 16,401 lượt tải in the section OMNISCAN X3.

Show word 1 next 9 in total 9 file.

OMNISCAN X3

» 1.5 MiB - 2,116 hits - 1 November, 2019

Product Catalog OmniScan X3

» 11.9 MiB - 1,643 hits - 20 November, 2020

OmniScan MXU Software (English)

» 626.0 KiB - 1,742 hits - 20 November, 2020

OmniScan X3 Getting Started Guide

» 10.7 MiB - 1,778 hits - 20 November, 2020

OmniScan X3 Manual (Vietnamese Version - First Version)

» 15.0 MiB - 2,913 hits - 13 November, 2020

OmniScan X3 Training Program (English)

» 15.2 MiB - 1,537 hits - 13 November, 2020

OmniScan X3 Training Program (Vietnamese)

» 2.2 MiB - 1,492 hits - 20 November, 2020

OmniScan X3 User's Manual (English)

» 1.2 MiB - 1,712 hits - 1 November, 2019

OmniScan X3 Catalog 201910 Tieng Viet

» 1.4 MiB - 1,468 hits - 26 July, 2022

OmniScan X3 64 Catalog (English)

Related Articles

About AIM – TFM Acoustic Influence Map on OmniScan X3

Chi-Hang KwanGuillaume PainchaudBenoit LepageThe article was first presented at the Symposium...

2 Comments

Nov

What is TFM/FMC and the three advantages of FMC/TFM on the OmniScan X3

The OmniScan® X3 phased array ultrasonic tester (PAUT) comes with the ability to...

3 Comments

Nov

Effect of weld edge when using ultrasonic FMC/TFM

Using traditional ultrasonic in weld inspection Inspection method...

Apr

Q&A related to TFM

Technical explanation regarding false indications in TFM (Information from...

1 Comments

Nov

Amplitude Fidelity – What is amplitude fidelity in TFM and how does it affect test results

Summary Grid resolution of total focus ultrasound...

2 Comments

Dec

TFM – Full array transceiver ultrasonic testing technique – Pros and cons

Full Matrix Capture Ultrasound Inspection Technique Full matrix capture (FMC - Ultra...

Dec

Use FMC/TFM instead of AUT in pipeline testing

Ed GINZELOleg VOLF and Ben BROWN Introducing NDT in the production of welds...

Jul

Matters needing attention when planning the scan (Scan Plan) in Phased Array and TFM inspection for welds

History of “Scan plan” Scan planning is an indispensable step,...

1 Comments

Apr