The MEC-Pipescanners offer the following features and benefits in terms of defect assessment, integrity and monitoring support for both on- and offshore applications:

High defect detection sensitivity for pipes / pressure vessels with:

- diameter ranging from 3” to flat surfaces

- wall thickness up to 30mm

- coating thickness up to 8mm

- temperatures up to 170 deg C

- High inspection speed of approx. 20m/min

- Ability to detect internal and external defects from ≥ 10% WT wall loss

- Ability to detect defect size from Ø 3mm

- Ability to inspect different steel materials (carbon, stainless, duplex, super duplex, monel, etc)

- Ability to detect pitting, cracks and various types of corrosion like CO2, microbiological, ammonium chloride salt as well as under deposit corrosion

- Ability to inspect both horizontal and vertical pipes and vessels

- Minimal surface preparation prior to inspection

- Provision of real time inspection analysis including wall loss severity classification

- Separate reporting for both internal and external conditions with advanced colour defect mapping

The MEC-Pipescanners offer the following advantages in comparison to the Saturation Low Frequency Eddy Current Pipescanners:

- More powerful magnetic unit

- Integrated power supply / Eddy Current electronics

- Fast magnet on/off switch

- Eddy Current electronics with single sensor pre-gain

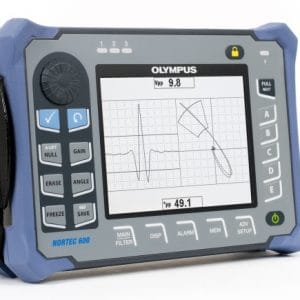

- Data acquisition via either TCP or RS422 and with a standard rugged notebook

- Poleshoes and wheel sets compatible

- Six different lift-off settings with the same wheel holder

- Power supply in an easy-to-carry Pelicase box

- Optional headset for communication