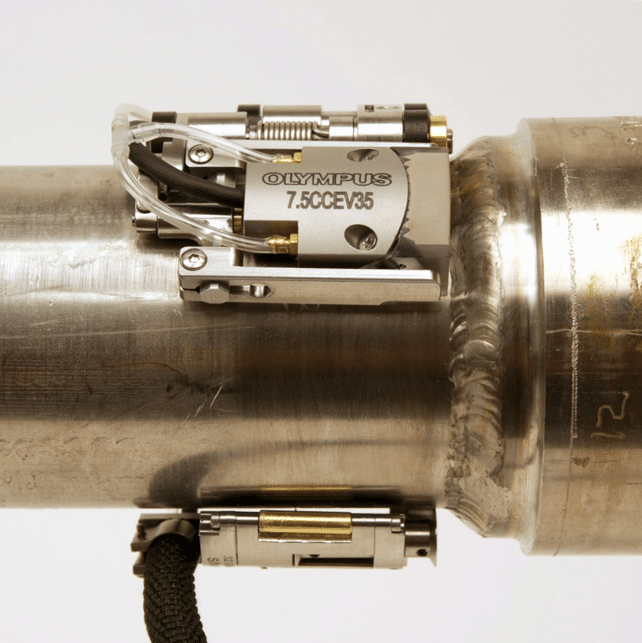

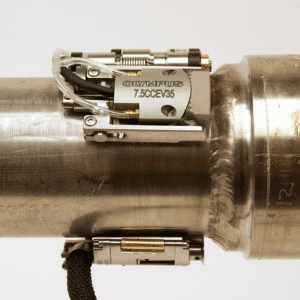

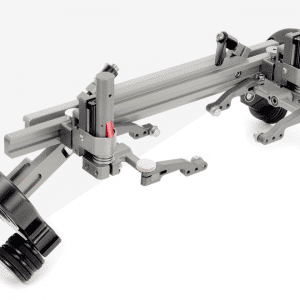

With a slim design, this semi-automatic ultrasonic scanner inspects pipes in restricted access areas, requiring minimal clearance. Parts that restrict access, such as pipes, brackets, and support structures should have a minimum clearance of 12 mm (0.5 in.). The sweeper has springs designed to clamp carbon steel and stainless steel pipes of different diameters using multiple small links. This unique feature allows the scanner to be mounted and operated from one side of the rows of tubes without reaching or using tools from the opposite side. The COBRA scanner is characterized by a smooth encoder tube ring movement, allowing for precise data collection. The scanner contains up to two probes PAUT nice TOFD to check the entire weld in one scan. For inspection of component-to-pipe or pipes with welds near the elbow, the scanner can be configured to perform Check from one side of the weld using a single probe.

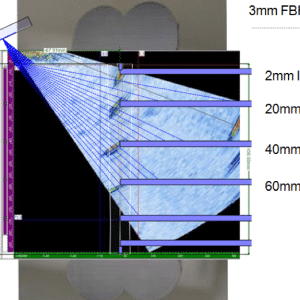

This Olympus solution utilizes low profile PAUT probes with optimized altimeter, which enhances detection of minor defects in thin-walled piping. Specially designed low profile wedges for each pipe diameter are available for a complete solution. The COBRA scanner ensures steady, constant transducer pressure, thus providing a quality UT signal and accurate encoding around the entire circumference of the pipeline.

The COBRA solution can be used with different probes, depending on the application. Phased array, TRL dual linear array and TOFD ultrasound techniques can be performed using the following transducer options:

Using low-profile PAUT probes with optimized height-detection AF improves detection of minor defects in thin-walled piping.

The COBRA scanner can also be configured to inspect component-to-pipe welds.

The TOFD test wedge is suitable for the COBRA scanner.

The A25 series of dual linear array (DLA) probes are designed to test austenitic materials where testing using the A15 probe is not possible.

Salient features

- For use on pipes from 0.84 to 4.5 in. OD (21 mm to 114 mm).

- Minimum height is only 12 mm (0.5 in.) (on standard tubes), can work in limited access positions.

- Using 2 probes at the same time helps to check the entire weld in one scan.

- Easy to install and adjust from one side, no tools required behind the tubes.

- Configurable for single-sided approach weld inspection.

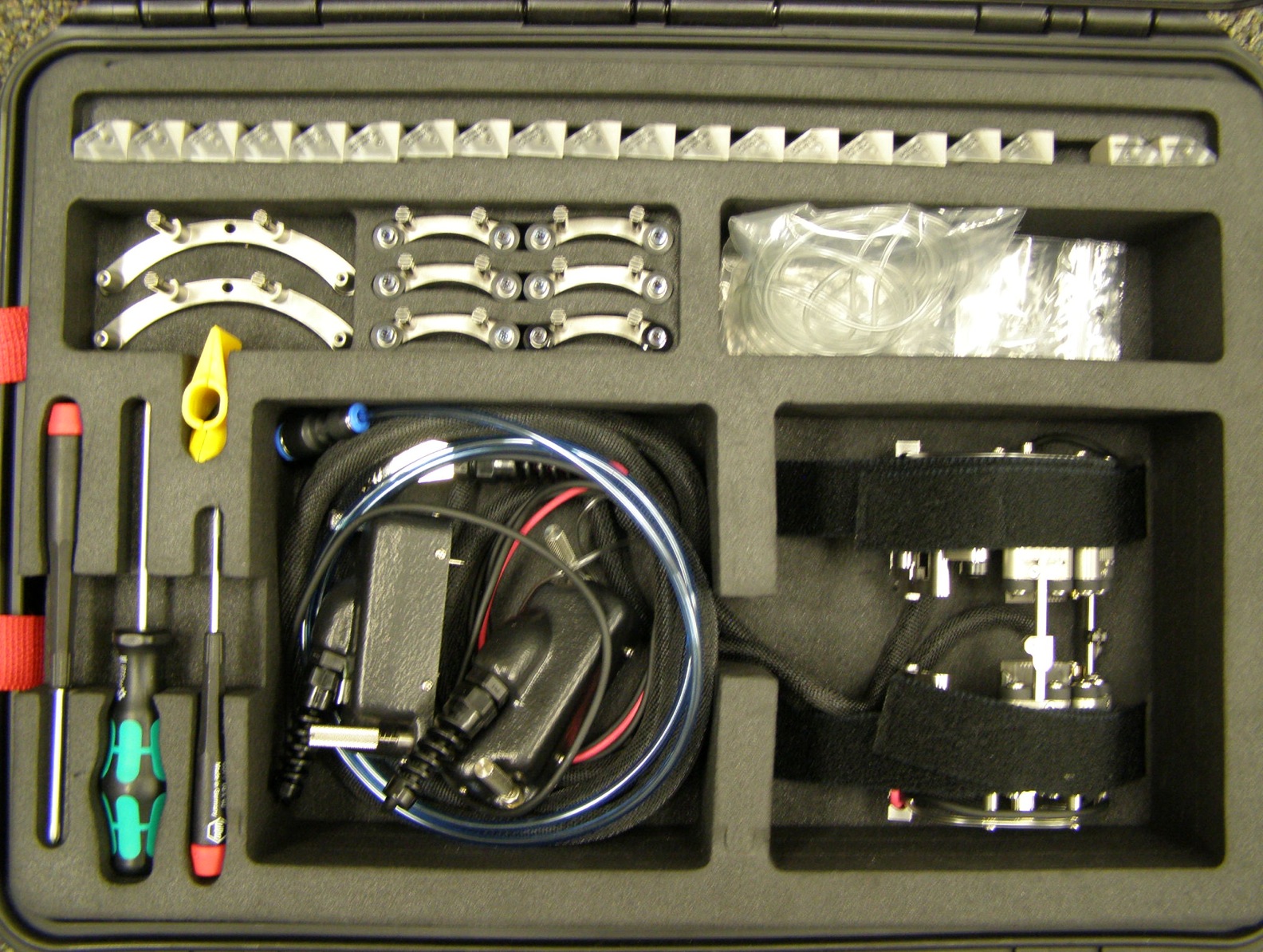

- Available templates make installation to a variety of pipe diameters easy.

- The device helps the transducer to be stable, the pressure is even when moving around the circumference of the tube.

- Rubber wheels for smooth movement and avoid shifting.

- Scanner resolution up to 32 steps/mm.

- Compact, lightweight, maneuverable.

- The probe and wedge can be easily changed.

- The distance between the two probes is configurable from 0 mm to 55 mm.

- The spring mechanism makes it possible to operate on both stainless steel and plain steel pipes.

- Rust-proof and water-resistant.

Frequently asked questions about using the COBRA scanner (FAQ)

1. Minimum thickness that can be tested with COBRA probe on small diameter pipes?

It is not possible to give an exact figure for the minimum testable wall thickness. This parameter relates to the type of defect, the material, the noise in the material, and the skill of the equipment operator. It is the customer who will need to carry out the experimental tests and draw conclusions. Small diameter tubes also often attenuate the signal quite a bit when reflected on curved surfaces, and thin tubes may require multiple scans to be tested. Combinations of many of the factors above can cause difficulties when examining small and thin tubes.

2. Is the COBRA ultrasound scanner compatible with AUT codes?

Yes of course"! Scanners and equipment are an important part of a test process or sequence, written to comply with a standard or code. Information may include scan speed, location encoding capabilities, device linearity, software and version preferences, and device data storage capabilities that form part of the testing process. check.

COBRA helps to achieve and comply with the following testing standards:

- ASME CC 2235

- ASME B31.3 CC 181

- ASME B31.1 CC 179

3. Can COBRA be used to inspect elbow or component-to-pipe welds?

Yes, if the straight pipe section on each side of the weld is sufficiently spaced, the test can be performed using two side probes. Otherwise, the scanner COBRA is configurable to perform inspection from one side of the weld.

4. What is the length of straight pipe on each side of the weld required when performing a COBRA inspection?

A minimum of 59 mm of flat tube is required to accommodate the COBRA scanner. For welds, it may be necessary to calculate half the weld width from the center, then the minimum distance will be 59 mm + half weld width.

Accessory order code COBRA

| U8907974 | COBRA-SP-ENC | Encoder Replacement for Cobra Scanner |

| U8775226 | Cobra-SP-Irrigation | Irrigation Kit for Cobra Scanner |

| U8908979 | Cobra-SP-YokeArm | Pair of yoke arms with screws for one yoke of the Cobra scanner. |

| U8907386 | 60BA0060 | Cobra cable sheathing -Autoclosing Sheath 3/8@5/8 – by the foot |

| U8909471 | 25CC0564 | Spring Cobra (LEFT probe holder assembly) |

| U8909470 | 25CC0563 | Spring Cobra (RIGHT probe holder assembly) |

| U8909468 | 25AA2123 | DGS017-R Probe holder left |

| U8909469 | 25AA2124 | DGS017-L Probe holder right |

| U8909466 | 25AA2125 | DGS003-LTail link assy (without encoder) |

| U8909467 | 25AA2108 | DGS003-R Tail link assy (with encoder) |

| OmniScan Common Accessories | ||

| U8760010 | OMNI-A-BATT | OmniScan battery pack |

| U8764053 | OMNI-A-SHCASE | Small black hard carrying case (19-1/8 in. x 15-7/16 in. x 7-9/16 in. / 48.6 cm x 39.2 cm x 19.2 cm) |

| U8767093 | OMNI-A-AC | OmniScan AC adapter |

| U8775201 | OMNI-A2-ADP20 | Scanner interface adapter to connect scanners encoder cables with DE15 connector to OmniScan MX2 with Lemo connector scanner interface. |

| U8780306 | OMNI-A2-SDCard | SDHC Card for OmniScan MX2 |

| U8780305 | OMNI-A2-ScreenProtec | Kit of 5 anti-glare touch screen protectors for OmniScan MX2 |

| U8780307 | OMNI-A2-USBDrive | Mini USB drive for OmniScan MX2 |

| U8780317 | OMNI-A2-STYLUS | 5 Stylus kit for touchscreen use |

| U8767077 | OMNI-A-CHRG | External battery charger |

| Common Probe and Wedge Parts | ||

| U8330826 | 7.5CCEV35-16-8X10-A15-P-2.5-OM | Standard Phased Array Probe, 7.5 MHz Concave Elevation Focused Array 35 mm Radius, 16 Elements, 8×10 mm Total Active Aperture, 0.50 mm Pitch, 10 mm Elevation, A15 Case Type, Impedance Matching to Rexolite, PVC Sheathing, 2.5 m Cable Length , Omiscan Connector |

| U8331014 | 10CCEV35-32-8X7-A15-P-2.5-OM | Standard Phased Array Probe, 10 MHz Concave Elevation Focus 35 mm Radius, 32 Elements, 8×7 mm Total Active Aperture, 0.25 mm Pitch, 7 mm Elevation, A15 Case Type, Impedance Matched to Rexolite, PVC Sheathing, 2.5 m Cable Length, OmniScan Connector |

| U8331163 | 5CCEV35-16-8X10-A15-P-2.5-OM | Standard Phased Array Probe, 5.0 MHz Concave Elevation Focused Array 35 mm Radius, 16 Elements, 8×10 mm Total Active Aperture, 0.50 mm Pitch, 10 mm Elevation, A15 Case Type, Impedance Matching To Rexolite, PVC Sheathing, 2.5 m Cable Length , OmniScan Connector |

| U8331117 | 2.25CCEV35-16-8X10-A15C-P-2.5-OM | Custom Phased Array Probe, 2.25 MHz Concave Elevation Focused Array, 35 mm Radius, 16 Elements, 8×10 mm Total Active Aperture, 0.50 mm Pitch, 10 mm Elevation, Custom A15 Case Type, Impedance Matching To Rexolite, PVC Sheathing, 2.5 m Cable Length, OmniScan Connector |

| U8779635 | SCREWKIT-1-64-CAPTIVE-CUSTOM | Kit of (16x) SCRW-10010, Screw 1-64 Captive Custom Screws for A15 Case Style |

Probe order code A15

| Part Number | Item Number | Freq. (MHz) | Number of Elements | Pitch (mm) | Elevation (mm) | Elevation Curvature Radius (mm) |

| 2.25CCEV35-A15C-P-2.5-OM* | U8331117 | 2.5 | 16 | 0.5 | 10 | 35 |

| 3.5CCEV35-A15C-P-2.5-OM* | U8331149 | 3.5 | 16 | 0.5 | 10 | 35 |

| 5CCEV35-A15-P-2.5-OM | U8331163 | 5.0 | 16 | 0.5 | 10 | 35 |

| 7.5CCEV35-A15-P-2.5-OM | U8330826 | 7.5 | 16 | 0.5 | 10 | 35 |

| 10CCEV35-A15-P-2.5-OM | U8331014 | 10.0 | 32 | 0.3 | 7 | 35 |

These probes come standard with an OmniScan® connector and a 2.5 m (8.2 ft) cable.

* A15C casing are based on the same design as the A15 but are 2 mm taller, increasing height clearance.

Probe order code A25

| Q3301132 | 5DL16-12X5-A25-P-2.5-OM | Standard Phased Array Probe, 5 MHz, Dual 16 Element Arrays, 12×5 mm Total Active Aperture, 0.75 mm Pitch, 5 mm Elevation, A25 Case Type, Impedance Matching to Rexolite, PVC Sheathing, 2.5 m Cable Length, 1X Omniscan Connector. |

| Wedge probe A25/Wedges | ||

| Q7201159 | SA25-DN70L-Kit | One (1) SA25-DN70L flat wedge plus nine (9) SA25-DN70L curved wedges to cover nominal pipe sizes (NPS) with outside diameters ranging from 0.84in to 4.5in. Features IH option (Irrigation and scanner Holes). To fit A25 Dual array probes. IMPORTANT NOTE: Focal laws for OmniScan using this solution cannot be created in the OmniScan. NDT SetupBuilder is required to create focal laws for the OmniScan. Tomoview can also be used. This solution will increase minimum height clearance required for use of the Cobra scanner. |

| Q7201141 | SA25-DN70L3.8-IH | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 3.8° Roof Angle, with IH option (Irrigation and Holes). |

| Q7201150 | SA25-DN70L11-IH-AOD1.05 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 11° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 0.84 in. (21.34 mm) to 1.05 in. (26.67 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201149 | SA25-DN70L10-IH-AOD1.315 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 10° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 1.05 in. (26.67 mm) to 1,315 in. (33.4 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201148 | SA25-DN70L8.5-IH-AOD1.66 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 8.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 1,315 in. (33.4 mm) to 1.66 in. (42.16 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201142 | SA25-DN70L8-IH-AOD1.9 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 8° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 1.66 in. (42.16 mm) to 1.9 inches (48.26 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201147 | SA25-DN70L7.5-IH-AOD2.375 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 7.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 1.9 in. (48.26 mm) to 2.375 in. (60.33 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201146 | SA25-DN70L6.5-IH-AOD2.875 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 6.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 2.375 in. (60.33 mm) to 2.875 in. (73.03 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201145 | SA25-DN70L6-IH-AOD3.5 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 6° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 2.875 in. (73.0 3 mm) to 3.5 in. (88.9 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201144 | SA25-DN70L5.5-IH-AOD4 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 5.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 3.5 in. (88.9 mm) to 4 in. (101.6 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Q7201143 | SA25-DN70L5.5-IH-AOD4.5 | Wedge for Dual Phased Array probe A25, Normal Scan, 70° Refracted Angle in Steel, Longitudinal Wave, 5.5° Roof Angle, with IH option (Irrigation and Holes). This wedge features a curvature matching 4 in. (101.6 mm) to 4.5 in. (114.3 mm) Axial Outside Diameter (AOD) Pipe for inspection of Circumferential Welds. |

| Spare Parts/ Spare Parts | ||

| Q3301131 | SCREW KIT, 1-64 X 1/8″ CAPTIVE CUSTOM | Kit of (16x) Screw 1-64 x 1/8” Captive Custom, for A25 Case Style |