Compact in size and rugged, the degaussing device of ZChem helps to quickly and effectively demagnetize many parts of different shapes and sizes.

The main applications of the degaussing device

- Parts after performing magnetic particle test.

- Eliminate residual magnetism in components intended for use near magnetometers.

- Degaussing parts with bearing surfaces subject to friction and magnetization.

- Parts after contact with magnetic chuck or lifting magnet.

Types of demagnetization systems

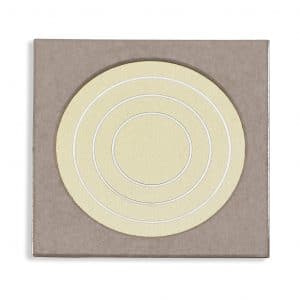

- Desktop Degausser with stainless steel slide and turntable.

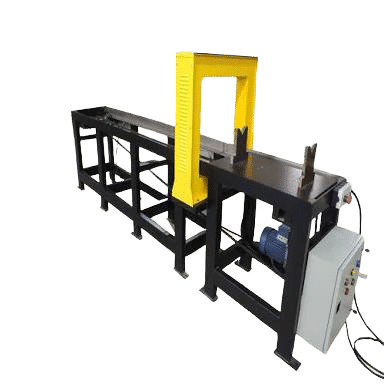

- Slider demagnetizer with trolley.

- The degaussing device uses a conveyor with an automatic Start/Stop sensor.

Specifications

- The degaussing range depends on the part size (The outside diameter of the part will determine the inner diameter of the degaussing coil).

- Can work in Intermittent Duty Cycle & Continuous Duty Cycle.

- Separate control panel with light switch & indicator.

- Power input source 230V for small coil size and 415V for larger coil.

- Water & oil resistant.

order information

- VC – 6: 6 Inch DC Mag-Demag Coil

- VC – 8: 8 Inch DC Mag-Demag Coil

- VC – 10: 10 Inch DC Mag-Demag Coil

- VC – 12: 12 Inch DC Mag-Demag Coil

- VC – 14: 14 Inch DC Mag-Demag Coil

- VC – 16: 16 Inch DC Mag-Demag Coil

- VC – 18: 18 Inch DC Mag-Demag Coil

- VC – 20: 20 Inch DC Mag-Demag Coil

Coil size can be customized according to customer requirements.