Olympus offers a complete advanced Phased Array ultrasonic inspection integration solution that meets the requirements of the most demanding customers. The solution includes the FOCUS PX, a powerful and scalable ultrasonic data collector; FocusPC, data collection and analysis software program; and two software development kits (SDKs), FocusControl and FocusData, to customize the look and feel of your software based on custom application and control FocusPC performs fully automated testing.

New wind coming from FOCUS PX

Excellent signal quality

The FOCUS PX delivers superb Phased Array signal quality using the latest technologies and advancements from Olympus, dramatically improving the signal-to-noise ratio.

More powerful and more flexible expansion

Up to 4 FOCUS PX units can be linked in parallel, delivering the fastest test speeds in multi-probe configurations.

Up to

4FOCUS PX parallel mounting

maximum bandwidth

30 MB/s

Simple and fast programming

FOCUS PX's optimized connection process significantly reduces programming time, helps get products to customers fastest, and enhances end-user experience.

Rugged design for industrial environments

Designed for industrial environments, the FOCUS PX features a rugged housing with protection for harsh environments. Designed to achieve IP65, the device's outer shell also features fins for rapid heat dissipation, increasing equipment life and uptime.

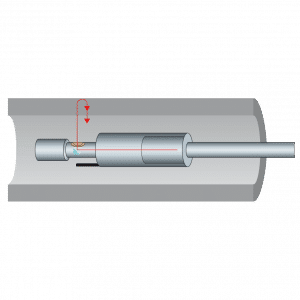

Easy to integrate

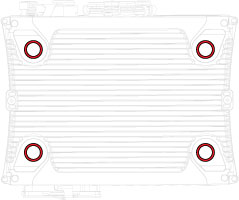

The FOCUS PX safety belts can be easily removed and the holes used to mount the product on the scanner or on the test system.

Easy to integrate

The FOCUS PX safety belts can be easily removed and the holes used to mount the product on the scanner or on the test system.

Easy to mount

Quick and easy installation and mounting make the FOCUS PX very close to the test site, reducing cable length and optimizing signal quality. Four screw holes are available to mount the unit in any position.

Get the most out of the FOCUS PX c with FocusPC Software

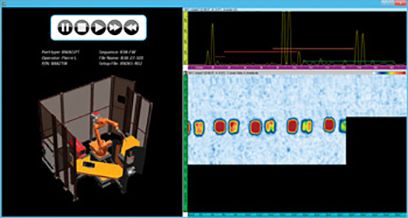

Olympus offers an integrated solution that meets your most demanding testing requirements. The solution includes FOCUS PX, which captures data and can extend its functionality with FocusPC software, a data analysis and processing software program, and three software development kits (SDKs), FocusControl, FocusData and OpenView SDK to customize the look and feel of your application-based software and fully automate FocusPC control.

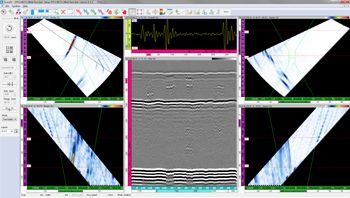

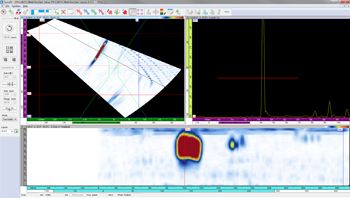

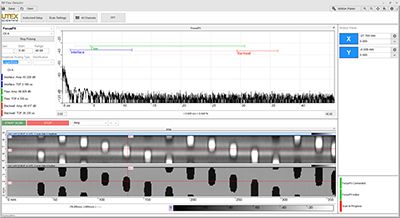

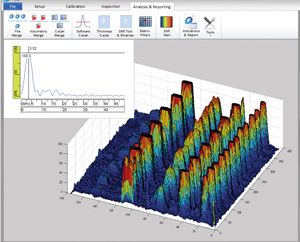

Convenient interface

FocusPC is designed for easy access to the most commonly used features, improving user experience and work efficiency.

Toolbar

Quick access to design, calibration, test and analysis features with intuitive toolbars.

Set the optimal display mode for installation, data acquisition and analysis

Split and reorganize windows according to your requirements.

Dashboard Dashboard

Convenient test mode and sequence management with quick dashboards.

Design:

Configure PA, UT, and TOFD test.

Calibration:

Wedge delay, sensitivity and TCG.

Test:

Optional test object structure and automatic control.

Analysis:

Optimal features for manual and automatic data analysis.

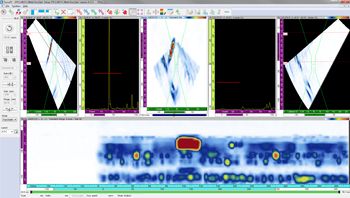

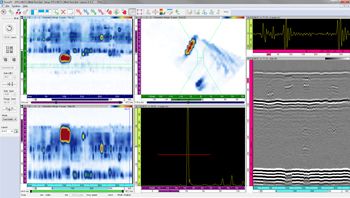

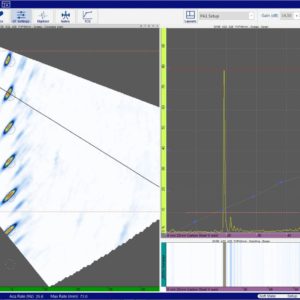

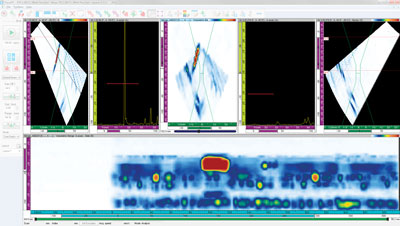

Advanced analysis tools

Advanced analysis tools available in FocusPC so you can get the most out of the test data you get from FOCUS PX. Use advanced data processing algorithms to extract valuable information and make analysis more efficient, resulting in more accurate conclusions.

Customize display mode as required

FocusPC maybe Customize the display to better serve specific application requirements. Each screen mode also has a variety of changeable options, optimizing user experience and operating efficiency. Split and reorganize different screen modes to create layouts when setting up systems or analyzing data.

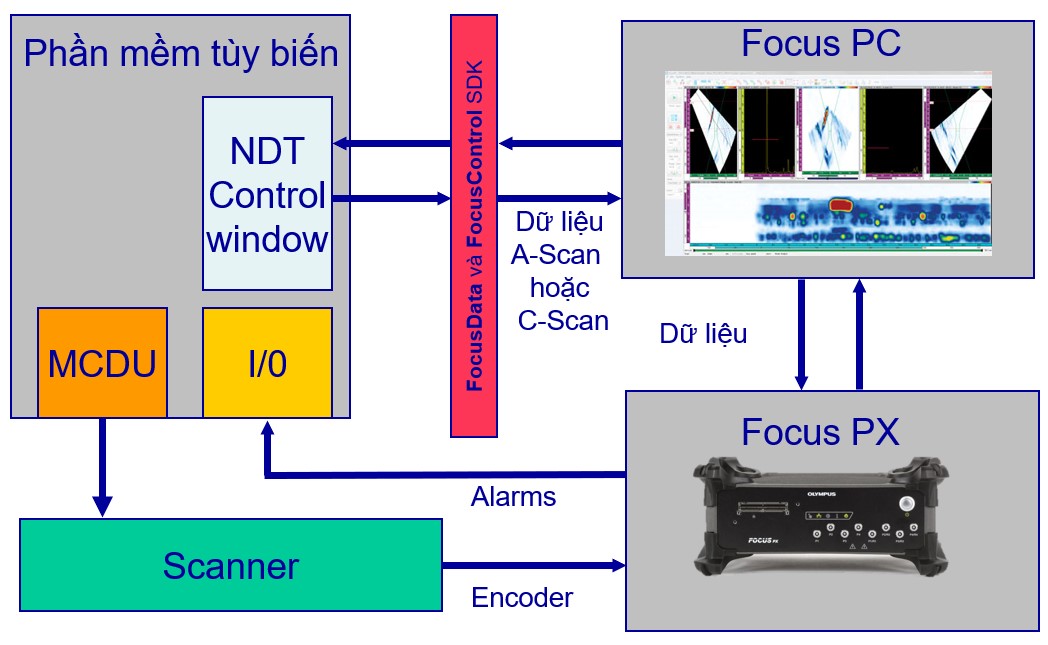

Software Development Kit (SDK)

Beyond software FocusPC and WeldSight For use with the Focus PX, Olympus also provides three software development kits (SDKs): FocusControl, FocusData and OpenView The SDK helps to customize the look and feel of your software based on your specific application, and the FocusPC control is fully automated and integrated into existing production lines.

OpenView SDK

For apps that require specific features or custom skins that can't be done with FOCUS PC nice WeldSight, OpenView SDK allows you to create your own control interface and features for your application such as camera integration, defect location marker. OpenView SDK compatible with industrial software PaymentWare are from UTEX and library HaroUT LabView are from Harotek making software development for the PAUT ultrasonic inspection solution never so easy and fast.

Automate the test process

Use FocusData and FocusControl SDK for custom software development and control FOCUS PX integrates with fully automated devices, maximizing performance, reducing down time and improving overall system efficiency.

Automated or custom data analysis

Use the SDK to gain direct access to test data from your software, enabling the development of application-specific data representations and on-demand analysis tools.

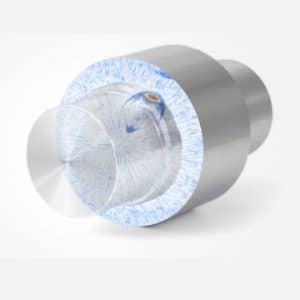

Robots, climbers, crawlers and pigs

Inspection robots in NDT enable data collection for more accurate and efficient maintenance planning, thereby reducing system downtime, increasing availability of industrial facilities, and bringing more profitable, promoting the safety of people and the environment. We always work with system integrators and bring automated testing solutions.

The Focus PX is an ultrasonic data processor and receiver that can be easily integrated into PA and UT automated test systems.

Some of the main applications

Inspection of friction stir welds using ultrasonic

What is Friction Welding? Before we break down into different types of solder...

Check longitudinal beams and splits in propeller posts with low frequency Phased Array ultrasound

Application The solution uses phased array ultrasound to check the girder cap...

Advances in the use of ultrasound in the inspection of 9% Ni welds in LNG tanks

LNG storage tanks LNG storage tanks require supercooling...

Automatic Tram/Train Wheel Inspection System Using Ultrasonic

Test tram wheels according to AAR, ISO and EN standards Transport...

Specifications

|

|

| Phased array channels | 16:64PR: 6416:128PR/32:128PR: 128 |

| Number of pulsers | 16:64PR/16:128PR: 16 consecutive elements32:128PR: 32 consecutive elements |

| Conventional UT channels | 4 dedicated UT channels(8 connectors for pulse-echo and pitch-catch configurations support) |

| Data acquisition rate | Up to 30 MB/s (1 FOCUS PX)Up to 60 MB/s (2 to 4 FOCUS PX) |

| Acquisition speed | Up to 20000 12-bit A-scans/second of 750 points each |

| Amplitude resolution | 8-bit / 12-bit |

| Maximum number of A-scan samples | 16380 |

| Real-time data compression | 1 to 2000 ratio |

| Rectification | FW, HW+, HW–, and RF |

| Filtering | Digital band-pass, high-pass and low-pass filters |

| Voltage | PA : 4 V, 9 V, 20 V, 40 V, 80 V, and 115 VUT : 50 V, 100 V, and 190 V |

| Gain | PA : 80 dB (46 dB analog + 34 dB digital)UT : 120 dB (digital) |

| Pulse width | PA : 30 ns to 500 ns (steps of 2.5 ns)UT : 30 ns to 1000 ns (steps of 2.5 ns) |

| Bandwidth (-3 dB) | PA : 0.6 MHz to 17.8 MHzUT : 0.25 MHz to 28 MHz |

| Number of beams | Up to 1024 |

| Pulse repetition frequency (PRF) | 1 Hz to 20 kHz |

| Real-time averaging | PA : 1, 2, 4, 8, 16UT : 1, 2, 4, 8, 16, 32, 64 |

| Number of gates | 4 for detection; 1 for synchronization |

| Encoder | 2 axes (quadrature, clock direction) |

| Network interfaces | 1000BASE-BILLION |

| Size (W x H x D) With bumpers | 30.7 cm × 13.5 cm × 23.6 cm (12 in. × 5.3 in. × 9.3 in.) |

| Size (W x H x D) Without bumpers | 27.6 cm × 9.2 cm × 23.1 cm (10.9 in. × 3.6 in. × 9.1 in.) |

| Weight With bumpers | 4.8 kg (10.5 lb) |

| Weight Without bumpers | 4.2 kg (9.2 lb) |

| IP rating | IP65 |

Ordering Information/Ordering Information

FOCUS PX

- FPX-1664PR: FOCUS PX 16:64PR + 4 UT channels

- FPX-16128PR: FOCUS PX 16:128PR + 4 UT channels

- FPX-32128PR: FOCUS PX 32:128PR + 4 UT channels

- FPX-UT4: Focus PX 4 UT channels

- FPX-UT4-FPC: Focus PX 4 UT channels with Software included

- FPX-OPT-2: Accessories for 2 FOCUS PX multipod configuration

- FPX-OPT-3: Accessories for 3 FOCUS PX multipod configuration

- FPX-OPT-4: Accessories for 4 FOCUS PX multipod configuration

FocusPC and SDK

- FPC-10-F: FocusPC 1.0 inspection and analysis software

- FPC-10-A: FocusPC 1.0 analysis software

- FDATA: FocusData SDK

- FCONTROL: FocusControl SDK

- FPC-INTEG: FocusPC 1.0 Full, FocusControl, FocusData and onsite training and support (special pricing)

Accessory

- [U8800440] E128P5-0000-OM: Extension Cable for Phased-Array Probe, OmniScan female to OmniScan male connector, for 128 elements instrument, 5m long, PVC outer jacket, No LEMO-00 UT connectors

- [U8767016] OMNI-A-ADP05: Y adaptor to link 2 Phased Array probes with OmniScan connectors to an instrument with one OmniScan connector input. Needed for Multi-probe capability with the OmniScan MX or FOCUS LT. IMPORTANT NOTE: This adaptor CAN NOT be connected directly to the OmniScan MX2. To make the connection, a PA extension cable is needed (E128P type) or the new OMNI-A2-SPLIT models should be considered. Also, this adaptor is only compatible on 128 elements modules.

- [U8767344] E32P1-32UT-OM: Adaptor for up to 32 conventional UT probes with LEMO-00 connectors to an instrument with an Omniscan connector. Supplied with a 1m long cable.

More info on Olympus FOCUS PX product page