NBIC

The National Commissioning Inspection Code (NBIC) requires pressure vessels to be check at 1/2 of the remaining life of the tank, or every 10 years, whichever is less.

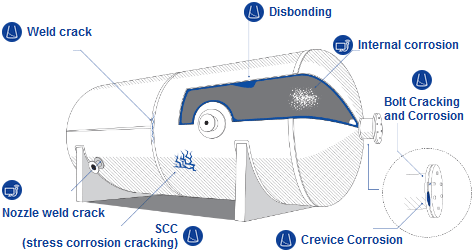

Pressure tank

A pressure vessel is a vessel that holds a liquid or gas at a pressure significantly different from atmospheric pressure. Pressure vessels can be found in industrial facilities around the world. The main applications of pressure vessels include boilers, engine cylinders and chemical or petroleum products storage tanks.

While pressure vessels are extremely useful and will likely continue to be widely used in the future, they can cause many problems. The difference between the pressure inside the pressure vessel and the pressure outside causes potentially dangerous situations. Pressure accumulators have long been considered dangerous and have caused accidents that have resulted in loss of life and property. Therefore, the construction and use of pressure vessels is regulated by technical agencies, and these agencies are supported by government legislation.

These standards also specify the need for testing and include instructions on the procedure for testing pressure vessels. Inspection of pressure vessels is both a requirement and a guide for anyone looking to avoid accidents that can lead to unplanned downtime, damaged equipment, and worker injury.

Classification of pressure tanks

Pressure vessels are designed differently based on their end application, although they all tend to look similar and consist of the same basic components. Pressure vessels are usually round or spherical in shape. That's because these shapes help avoid concentrated stress.

Common accessory sections include pressure gauges, fusion plugs, and differential pressure switches, which make the compressor operate when pressure drops and shut down when pressure is at maximum. Most pressure vessels are also designed with technical access holes, ventilation holes or viewing holes to facilitate cleaning and inspection.

In addition to the shape, the pressure vessels also perform different functions. The basic way to classify pressure vessels is to divide them into two categories – fire exposed and non-flame, or non-heated. A good example of a fire-contact pressure vessel would be a boiler. Non-flame pressure vessels must not be connected to any steam generator or to anything with an open flame.

We can divide accumulators into several different categories. Although there are some exceptions, the most common pressure vessels fall into three categories: reservoir, heat exchanger, and process vessel.

Standards in pressure tank manufacturing

- Standard for Construction of Pressure vessel

- ASME BPVC Section VIII- Division 1 (Part UG)

- Materials Selection – Section II (Part A – Ferrous, Part B- Non Ferrous, Part D- Properties)

- Welding Materials Selection– Section II (Part C)

- Material Thickness, of Shell & tube are calculated based on the Design

- Pressure, Design Temperature, Radius of Shell & the Weld Joint Efficiency,

- Weld Joint Efficiency – Selection (as per ASME Sec VII, Div 1, Table UW-12)

Check pressure tank

Non-destructive testing of boilers and pressure vessels is a test of the integrity of equipment and is usually approved by OSHA, API, ASME or in Vietnam, the Ministry of Labour, Invalids and Social Affairs (National Standard). (originally issued under Decision No. 64/2008/QD-BLDTBXH dated November 27, 2008) and other regulatory authorities required to ensure safe and reliable equipment. Pressure vessel owners are required to develop, document, and implement an inspection/repair plan that outlines procedures to meet required standards. Such plans usually require the tester to perform periodic inspections, provide test results, documented failures/defects.

There are two standards that every pressure vessel manufacturer and user must keep in mind:

- ASME Section VIII: requirements for fired and unheated pressure vessels, including design, manufacture, inspection and testing, and requirements for pressure vessels to be certified.

- API 510: is the American Petroleum Institute's pressure tank test code. This standard specifies how to carry out inspection, repair, alteration and other operations for pressure vessels and pressure reducing devices.

The National Commissions Inspection Code (NBIC) requires pressure vessels to be tested at 1/2 of the remaining vessel life, or 10 years, whichever is less. Whenever the remaining life is less than 4 years, the inspection interval will be established by the tester based on the condition of the equipment and the rate of corrosion assessed against the periodic test data.

The NDT solutions offered by VISCO provide comprehensive inspection of process equipment and tanks as well as providing industry-formatted information for taking preventive measures, failure status, life assessment and corrosion assessment.

Check out the newly manufactured pressure vessel

- Check the welding process

- Check the welder's qualification record

- Check Material Inspection Report

- Post-weld heat treatment practice test

- Pneumatic or hydraulic test

- Non-destructive testing

In-use pressure tank test (ISI)

- External check: Visually every 5 years or earlier.

- Internal assessments, online measurements and thickness gauges.

- Pressure relief devices shall be inspected, tested and maintained in accordance with API 576

- Unless the experience is documented and/or RBI . rating indicates that a longer time period is acceptable

- Test and inspection intervals for pressure relief equipment in typical process services shall not exceed:

- 5 years for general services, and

- 10 years for clean (non-fouling) and non-corrosive services.

NDT inspection of pressure tanks

- Heat exchanger rating check using ECT, ECA, NFT, RFT, MLF, IRIS, ARP and RVI.

- Ultrasonic thickness test and Corrosion mapping.

- Endoscopic joints and pipes.

- MT, PT and ECA corrosion rating test and crack SCC.

- Check for vacuum leaks.

- Identification of alloy used XRF.

- Analysis of causes of corrosion using XRD.

- Remaining life rating.

- Analysis of the coating.

The owner of the pressure vessel has an obligation to ensure its safe use. This requires effective inspection and maintenance programs. The owner is responsible for developing, documenting, implementing, implementing and evaluating pressure vessel testing systems and test procedures to meet relevant requirements. These systems and procedures typically include:

- Organization and reporting structure of the inspection

- Documentation and procedures for maintaining testing and quality assurance procedures

- Documentation and report of test results

- Corrective actions for inspection and test results

- Internal audit of compliance with quality assurance inspection manual

- Review and approve drawings, design calculations and specifications for repairs and alterations.

On-site visual inspections and use of RVI as well as non-destructive testing (NDT) to certify compliance and service suitability of pressure structures. The diverse and customer-centric solutions offered by VISCO are used to detect structural flaws in plant equipment, providing owners and operators with essential data for efficient and safe operation.

Inspection of pressure equipment includes inspecting the body and top of the tank, critical parts or areas for possible corrosion. Visual inspection is generally accepted but often requires equipment to be shut down and affects productivity. Visual inspection is also used to determine the condition of the outer insulation, the allowable expansion range and the position of the pressure devices on the support. Any signs of leakage should be investigated to determine the source of the problem.

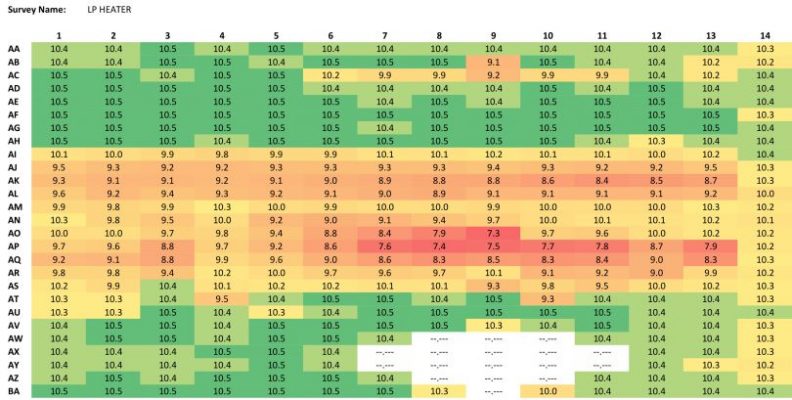

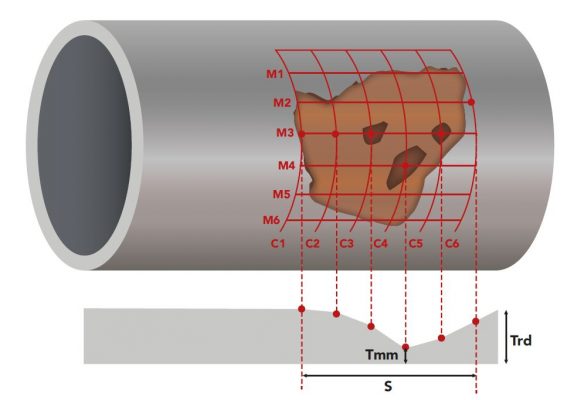

Ultrasonic thickness measurement

Ultrasonic corrosion thickness test use devices such as 38DLP nice EPOCH 650 with the ability to save data in 1D or 2D grid format to determine the internal condition and remaining thickness of the tank and tank walls. Thickness measurements are collected in grid data while the pressure device is in operation or at shutdown by an inspector with expertise in ultrasonic testing. With advances in technology and data processing and reporting capabilities, more and more equipment capable of capturing thickness data as the scan head moves across the test surface is being used more and more. Test results can be viewed in the field or stored for later analysis.

- Setup and detection is easy and fast with the dedicated probes for corrosion assessment and testing.

- Measure the remaining thickness of the tank wall.

- Climb to the top of the tank with the compact ultrasonic device.

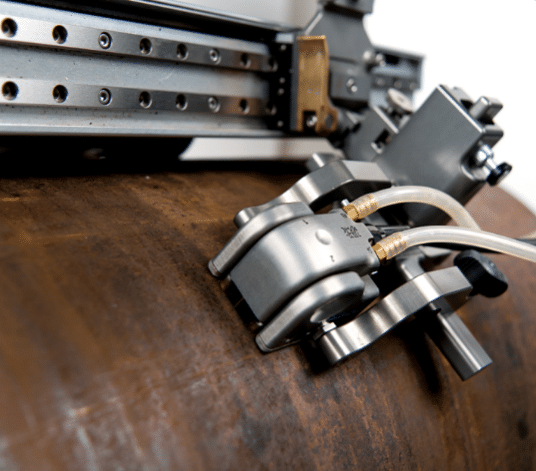

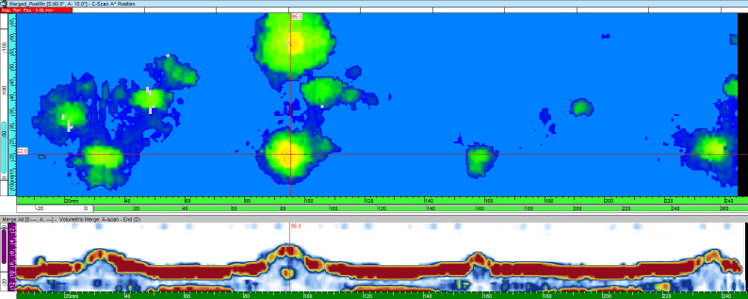

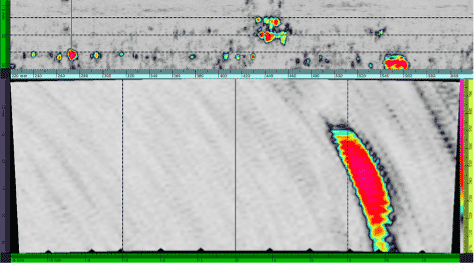

Corrosion Mapping

Ultrasonic Corrosion Mapping is the commonly used method while inspecting pressure vessels. Ultrasonic Erosion Mapping provides owners with detailed C-Scan images of the inspected surface using position coded semi-automatic scanners. ChainSCANNER or MapSCANNER in combination with corrosion inspection Phased Array probes offer high-speed ultrasonic mapping options for circumferential scanning.

Instruments such as MapROVER or SteerROVER are designed to map the corrosion of difficult-to-reach areas using semi-automatic scanners. In addition, the DLA probe used as a standalone manual solution offers good surface resolution and is usable at high temperatures.

The complete dedicated scanners solve the problem of corrosion mapping for small pipes and tubes with many elbow bends that can be solved with the FlexoFORM scanner and the flexible PAUT probe.

Simply connect the probe/scanner to a Phased Array device such as the OmniScan SX or OmniScan X3 to create a semi-automatic phased array erosion mapping system with built-in data collection capabilities.

Phase array eddy current

For decades, penetrant testing (PT) has been a common method used to test the surface of stainless steel pressure vessels. Currently, technology Phase array eddy current (ECA) can make this check faster and more reliable.

Surface inspection of stainless steel pressure vessels presents many challenges such as the geometry of the weld cap, the surface coating. Test solution MagnaFORM™ Using ECA overcomes these challenges with many advantages.

- Lift-Off Compensation Technology

- Durable design to work even with rough surfaces.

- Sensitivity can detect imperfections as small as 1.6 mm (0.06 in.) with a paint-through inspection probe up to 3 mm.

- No need to remove the paint.

- The signal is easy to interpret like the traditional PT method.

- Install inspection on both sides of welds with 304 and 316 steel commonly found in pressure tanks.

Resources

Hướng dẫn cho người không chuyên về các tiêu chí chấp nhận khi kiểm tra siêu âm

Kiểm tra siêu âm (UT) đóng vai trò then chốt trong việc đánh giá chất lượng và tính toàn vẹn của vật...

Phương pháp tiếp cận khi đánh giá ăn mòn dưới lớp cách nhiệt (CUI) của hệ thống đường ống

Tham khảo thêm: Kiểm tra ăn mòn dưới lớp bảo ôn Một phương pháp tiếp cận từng bước trong quá trình kiểm...

Application of automatic ultrasonic inspection method instead of radiography in weld inspection

Tham khảo thêm: Siêu âm Phased Array sử dụng thay thế chụp ảnh phóng xạ Tóm tắt nội dung Bài viết này...

Câu hỏi thường gặp về quét kiểm tra ăn mòn sử dụng SRUT (GUL)

QSR1 ® là máy quét dễ sử dụng chuyên dụng để đo định lượng độ dày thành còn lại của các vị...

Ultrasonic thickness measurement technique skips the paint layer

Ứng dụng: Đo chính xác độ dày thành còn lại của ống kim loại, bể chứa, dầm, vỏ tàu và các cấu...

Kỹ thuật hình ảnh kết hợp pha PCI là gì và 5 ưu điểm của PCI

With the release of software MXU 5.10, the OmniScan™ X3 64 defect ultrasound device adds a...

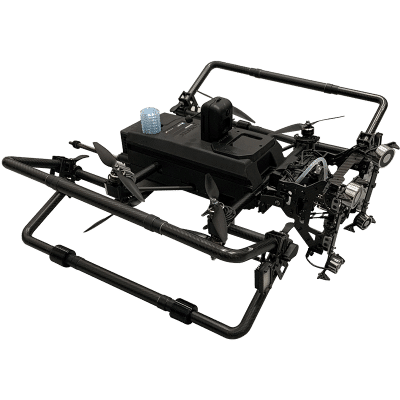

UT Drone: Kỷ nguyên mới của việc kiểm tra siêu âm trên cao

Trong những năm gần đây, việc tích hợp rô bốt trên không (máy bay không người lái) với máy đo độ dày...

Thử nghiệm: Phân tích dầu nhiên liệu sử dụng XRF cầm tay

Dầu nhiên liệu cần được giám sát cẩn thận Thử nghiệm tại chỗ dầu nhiên liệu đã trở thành một nhiệm vụ...

Wedge Phased Array for use in ultrasonic testing as high as 150°C

Giới thiệu Thực hiện kiểm tra siêu âm mảng điều pha Phased Array trên các bộ phận và thành phần nhiệt độ...

Equipment Eligibility Assessment (FFS)

Đánh giá FFS là gì? Đánh giá FFS (Fitness-for-service) đối với các thiết bị được định nghĩa trong API 579-1/ASME FFS-1. Fitness-for...

Một ngày làm việc của nhân viên kiểm tra NDT ngoài giàn khoan cùng bộ quét ăn mòn HydroFORM™

Tại Bilfinger UK có trụ sở tại Esbjerg, Đan Mạch, Raphael Mokri là một Kỹ sư dự án NDT. Văn phòng có...

Kiểm tra phát xạ âm trong phát hiện và giám sát ăn mòn dưới lớp bảo ôn

Ăn mòn và rò rỉ dưới lớp bảo ôn Ăn mòn dưới lớp bảo ôn (CUI) là một dạng ăn mòn cục...

Kiểm tra phát xạ âm của các bồn chứa hình cầu

Bình chịu áp lực hình cầu được sản xuất theo Bộ luật về bình chịu áp lực và nồi hơi của Hiệp...

Kỹ thuật Kiểm tra phát xạ âm – Acoustic Emission Testing

Giới thiệu về kỹ thuật kiểm tra phát xạ âm – AET Phát xạ âm (AE) đề cập đến việc sóng đàn...

XRF and XRD analysis application from A to Z

Portable X-ray analysis techniques such as XRF and XRD can be used to examine...

Inspect 95 mm (3.74 in.) multi-component welds using the A26 Dual Linear Array™ (DLA) probe.

Giới thiệu Trong lĩnh vực dầu khí, hóa dầu và sản xuất điện, các thành phần có thành dày thường được sử...

Perform FFS assessment for pressure equipment

The Fitness for Service (FFS) assessment is the standard and best method to use to determine how well...

Automated XRF sampling and analysis system on conveyor

Precise chemical analysis can provide important data to enhance mining operations, such as...

Equipment used in testing wind turbine blades

Structure of wind turbine blades The properties of wind turbine materials often have a great influence on...

Choose the right technique when checking coating thickness

Coating inspection is an important application of quality control in many components or products...

Video

Download

Have everything 233 file, size 388.5 MiB with 253,591 lượt tải in the section total.

Show word 1 next 20 in total 233 file.

VANTA

» 11.9 MiB - 0 hits - 3 April, 2024

» 4.3 MiB - 1,507 hits - 16 December, 2021

Application of XRF in the automobile manufacturing industry

» 1.8 MiB - 2,202 hits - 16 December, 2021

Application of XRF and XRD in geosciences

» 250.2 KiB - 1,540 hits - 16 December, 2021

Infographic of XRF application in the mining sector

» 183.3 KiB - 1,625 hits - 1 January, 2000

» 916.7 KiB - 1,478 hits - 16 December, 2021

Explain how XRF works as an image (Wall poster)

» 2.4 MiB - 1,785 hits - 16 December, 2021

XRF application analyzing iron-rich soil in Eeherrin, Virginia

» 1.6 MiB - 1,446 hits - 16 December, 2021

Quick introduction of the VANTA XRF device (4 pages)

» 1.4 MiB - 1,504 hits - 16 December, 2021

Introducing VANTA XRF in the field of environment

» 1.3 MiB - 1,488 hits - 16 December, 2021

Introducing Vanta XRF material validation in QA/QC

» 633.2 KiB - 1,579 hits - 16 December, 2021

Application programming interface with VANTA application in automated XRF testing

» 441.0 KiB - 1,580 hits - 16 December, 2021

Introducing groundbreaking Axon technology for fast testing and stable results on the VANTA XRF

» unknown - 0 hits - May 21, 2018

» 274.1 KiB - 1,513 hits - 16 December, 2021

Vanta XRF through the numbers

» 217.6 KiB - 1,557 hits - 16 December, 2021

Using VANTA XRF in precious metal analysis automotive exhaust catalysts (recycled)

» 353.9 KiB - 1,471 hits - 16 December, 2021

Application of Vanta XRF in the Cement manufacturing industry

» 1.3 MiB - 1,489 hits - 2 February, 2024

Catalog dòng sản phẩm VANTA (Tiếng Anh)

» 1.0 MiB - 1,768 hits - 2 February, 2024

Catalog dòng sản phẩm VANTA (Tiếng Việt)

OMNISCAN MX2

» 10.0 KiB - 1,145 hits - 17 September, 2019

Convergence law for A27 . probe

» 5.3 MiB - 2,440 hits - 7 December, 2014

OmniScan MX2 . User Manual

Other test standards related to pressure tanks

- API 570 Piping Inspection Code: In-Service Inspection, Rating, Repair, and Alteration of Piping Systems

- API Recommended Practice 571, Damage Mechanisms Affecting Fixed Equipment in the Refining Industry

- API Recommended Practice 572, Inspection of Pressure Vessels

- API Recommended Practice 576, Inspection of Pressure-relieving Devices

API Recommended Practice 577, Welding Inspection and Metallurgy - API Recommended Practice 578, Material Verification Program for New and Existing Alloy Piping Systems

- API Standard 579-1/ASME FFS-1, Fitness-For-Service

- API Recommended Practice 580, Risk-Based Inspection

- API Recommended Practice 581, Risk-Based Inspection Methodology

- API Recommended Practice 582, Welding Guidelines for the Chemical, Oil, and Gas Industries

- API Recommended Practice 583, Corrosion Under Insulation and Fireproofing

- API Recommended Practice 584, Integrity Operating Windows

- API Recommended Practice 585, Pressure Equipment Integrity Incident Investigations

- API 653 Tank Inspection, Repair, Alteration and Reconstruction

- API 610 Centrifugal Pumps for General Refinery Services

- API 6D Steel Gate, Plug, and Check Valves for Pipeline Service

- API 620 Design and Construction of Large Welded, Low Pressure Storage tanks

- API Recommended Practice 939-C, Guidelines for Avoiding Sulfidation (Sulfidic) Corrosion Failures in Oil Refineries

- API Recommended Practice 941, Steels for Hydrogen Service at Elevated Temperatures and Pressures in Petroleum

- Refineries and Petrochemical Plants

- API Recommended Practice 2201, Safe Hot Tapping Practices for the Petroleum and Petrochemical Industries

- ASME PCC-1 1, Guidelines for Pressure Boundary Bolted Flage Joint Assembly

- ASME PCC-2, Repair of Pressure Equipment and Piping

- ASME Boiler and Pressure Vessel Code, Section II: Materials

- ASME Boiler and Pressure Vessel Code, Section V: Nondestructive Examination

- ASME Boiler and Pressure Vessel Code, Section VIII: Rules for Construction of Pressure Vessels; Division 1

- ASME Boiler and Pressure Vessel Code, Section VIII: Rules for Construction of Pressure Vessels; Division 2: Alternative rules

- ASME Boiler and Pressure Vessel Code, Section IX: Welding and Brazing Qualifications

- ASNT CP-189 2, Standard for Qualification and Certification of Nondestructive Testing Personnel

- ASNT SNT-TC-1A, Personnel Qualification and Certification in Nondestructive Testing

- NACE MR0103 3, Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum Refining Environments

- NACE SP0170, Protection of Austenitic Stainless Steels and Other Austenitic Alloys from Polythionic Acid Stress Corrosion Cracking During Shutdown of Refinery Equipment

- NACE SP0472, Methods and Controls to Prevent In-service Environmental Cracking of Carbon Steel Weldments in Corrosive Petroleum Refining Environments

- National Board NB-23 4, National Board Inspection Code

- OSHA 29 CFR Part 1910 5, Occupational Safety and Health Standards