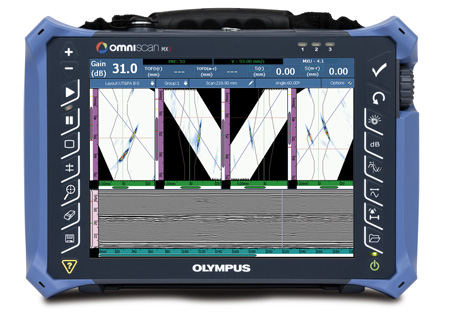

The result of over 10 years of proven leadership in modular NDT test platforms, the OmniScan MX has been the most successful portable and modular phased array test instrument produced by Olympus to date, with thousands of units in use throughout the world.

Olympus now offers a new PA module with TOFD, a new UT module, as well as new software programs (NDT SetupBuilder and new OmniPC version) that expand the capabilities of the successful OmniScan MX2 platform and improve the workflow efficiency of nondestructive testing inspections.

Xây dựng từ nền tảng vững chắc

This second generation OmniScan MX2 increases testing efficiency, ensuring superior, advanced AUT application performance with faster setups, test cycles, and reporting, in addition to universal compatibility with more than 10 phased array and ultrasound modules. Designed for NDT experts, this high-end, scalable platform delivers true next-generation NDT performance.

The OmniScan MX2 offers a high acquisition rate and new powerful software features for efficient manual and automated inspection performance—all in a portable, modular instrument.

用户手册

Faster Is Better!

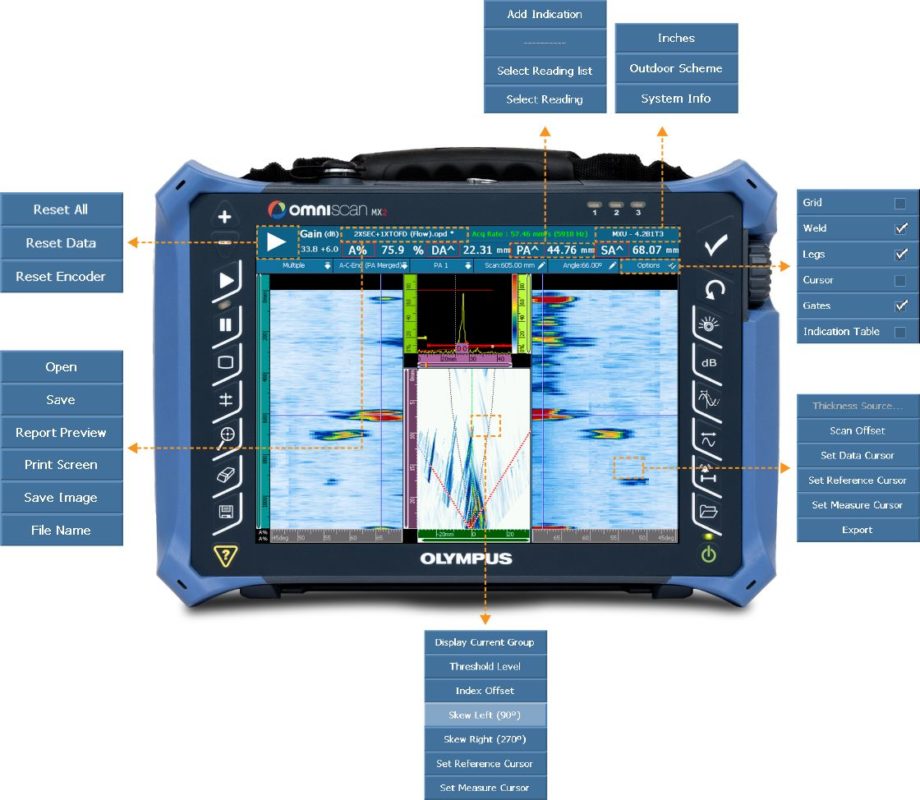

Powerstart your day with the OmniScan MX2. The OmniScan MX2 simplifies and speeds up the setup process with its intuitive step-by-step Wizard, so you can start testing quickly. Featuring the industry-standard phased array user interface with faster-than-ever performance, a bigger and brighter 10.4 in. (26.4 cm) screen, new and unique intuitive touch-screen capabilities, and faster data transfer, the MX2 enables you to get to your next inspection quicker.

Đầy đủ các giải pháp trong một thiết bị

The OmniScan MX2 is an important part of your inspection solution, and can be combined with other critical components to form a complete inspection system. Olympus offers a complete product range that includes phased array probes, scanners, analysis software, and accessories, all of which are integrated and packaged into rapidly deployable, application-specific solutions for a quick return on your investment. In addition, Olympus offers a high-quality global calibration and repair service, backed by a team of phased array application experts to ensure that you get the support you need.

Mối hàn thiết bị áp lực

A complete inspection of pressure vessel welds can be performed in a single scan using an OmniScan PA and manual scanner such as the HSMT series or a motorized scanner like the WeldROVER. By combining TOFD and PA in a single inspection pass, a significant reduction in inspection time can be achieved as compared with conventional raster scanning or radiography. Furthermore, inspection results are available immediately, enabling you to detect problems with welding equipment and fix them right away.

Kiểm tra composite

Parts made of laminate composite materials pose an inspection challenge due to their various shapes and thicknesses.

Olympus offers complete solutions for the inspection of carbon-fiber-reinforced polymer structures. These solutions are based on the OmniScan flaw detector, the GLIDER™ scanner, and dedicated probes and wedges designed for CFRP flat panel and radius inspection.

Mối hàn ống nhỏ

When coupled with the COBRA manual scanner, the OmniScan flaw detector is capable of inspecting pipes ranging from 0.84 in. OD to 4.5 in. OD. With its very slim design, this manual scanner is able to inspect pipes in areas with limited access. Adjacent obstructions such as piping, supports, and structures can be as close as 12 mm (0.5 in.).

腐蚀测绘

The OmniScan PA system with the HydroFORM scanner is designed to offer the best inspection solution for detecting wall-thickness reductions resulting from corrosion, abrasion, and erosion. In addition, this system detects mid-wall damage, such as hydrogen-induced blistering and manufacturing-induced delamination, and clearly differentiates such anomalies from loss-of-wall-thickness.

For this application, phased array ultrasound technology offers superior inspection speed, data point density, and detection.

Phần mềm hỗ trợ workflow

Thiết kế module tháo lắp

Thay thế module bạn cần

Designed to secure both your current and future phased array investments, the OmniScan MX2 houses more than 10 different Olympus modules. You can be confident that you will get the most out of your investment as specifications will continue to evolve with your needs through constant software updates.

Cấu hình module cho PAUT và UT

As a world leader in phased array technology, Olympus has released a new line of modules compatible with MX2 instrument.

Module PA2 với chất lượng nâng cấp

The new phased array offer-led by the new innovative PA2 modules, features multiple improvements, such as:

More Multi-group Capabilities

- Ability to use PA and UT channels simultaneously

General Hardware Improvements

- Higher operating temperatures (45 °C)

- New OmniScan probe connector with quick latch system

- Designed for IP66 environmental rating

- Extended autonomy on batteries

Module UT2 cho chất lượng siêu âm tuyệt hảo

The new conventional ultrasound module features the same UT-channel technology as the PA2 modules, but offers twice as many channels.

Best Phased Array and TOFD Signal Quality Ever

- Better signal-to-noise ratio

- More powerful pulsers

- 64 pure gray tone

Phần mềm dễ sử dụng

The new OmniScan software features enhancements for greater functionality in weld and corrosion markets.

In the effort for continuous improvement, the software interface was simplified and the response time optimized in order to provide the best experience possible for customers.

New features include:

- Export C-Scan

- New End-View with group merge

- Interleave

- Analysis attenuation gain

- Scrolling layouts for easy interpretation

- Improved accessibility with more interactive menus

- Optimised main menus and wizards

- Onboard compound scan

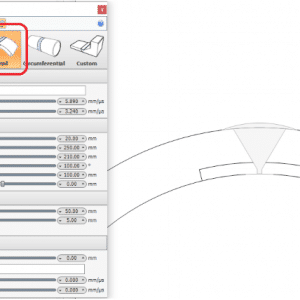

- Curved geometry ray-tracing for longitudinal welds

- Phased Array DGS/AVG for all focal laws with S-scan image correction

For applications requiring a multi-probe configuration, the multi-group layouts were improved so that the scanner configuration is reflected in the software interface. The position of the different scans is determined by their distance to the center of the weld, providing an easy-to-understand and appealing layout.

OmniScan MX2 Mainframe Specifications

| 一般的 | Overall dimensions (W x H x D) | 325 mm x 235 mm x 130 mm (12.8 in. x 9.3 in. x 5.1 in.) |

| 重量 | 3.2 kg (7 lb), no module and one battery | |

| 数据存储 | Storage devices | SDHC card*, most standard USB storage devices, or fast Ethernet. *Lexar® brand memory cards are recommended for optimized results. |

| Data file size | 300 MB | |

| I/O Ports | USB ports | 3 |

| Audio alarm | Yes | |

| Video output | Video out (SVGA) | |

| Ethernet | 10/100 Mbps | |

| I/O Lines | Encoder | 2-axis encoder line (quadrature, up, down, or clock/direction) |

| Digital input | 4 digital TTL inputs, 5 V | |

| Digital output | 4 digital TTL outputs, 5 V, 15 mA | |

| Acquisition on/off switch | Remote acquisition enabled TTL, 5 V | |

| Power output line | 5 V, 500 mA power output line (short-circuit protected) | |

| Alarms | 3 TTL, 5 V, 15 mA | |

| Analog output | 2 analog outputs (12 bits) ±5 V in 10 kΩ | |

| Pace input | 5 V TTL pace input | |

| 展示 | Display size | 26.4 cm (10.4 in.) (diagonal) |

| Resolution | 800 pixels x 600 pixels | |

| Brightness | 700 cd/m2 | |

| Number of colors | 16 million | |

| Type | TFT LCD | |

| 电源 | Battery type | Smart Li-ion battery |

| Number of batteries | 1 or 2 (battery chamber accommodates two hot-swappable batteries) | |

| Battery life | Minimum 7 hours with two batteries | |

| Environmental Specifications | 工作温度范围 | -10 °C to 45 °C (14 ºF to 113 ºF) |

| Storage temperature range | -20 °C to 60 °C (-4 ºF to 140 ºF) with batteries -20 °C to 70 °C (-4 ºF to 158 ºF) without batteries |

|

| Relative humidity | Max. 70% RH at 45°C noncondensing | |

| Ingress Protection Rating | Designed for IP66 | |

| Shockproof rating | Drop-tested according to MIL-STD-810G 516.6 | |

| MX2 Module Compatibility | MXU 4.1R8 and later | OMNI-M2-PA32128PR |

| MXU 4.0 and later | OMNI-M2-PA1664 | |

| OMNI-M2-PA16128 | ||

| OMNI-M2-PA32128 | ||

| OMNI-M2-UT-2CH | ||

| MXU 3.1 and MXU 4.1R12 and later | OMNI-M-UT-8CH |

Phased Array Module Specifications (Với module OMNI-M2)

| 一般的 | Overall dimensions (W x H x D) | 226 mm x 183 mm x 40 mm (8.9 in. x 7.2 in. x 1.6 in.) |

| 重量 | 1.6 kg (3.5 lb) | |

| Connectors | 1 Phased Array connector: Olympus PA connector 2 UT connectors: LEMO 00 |

|

| Number of focal laws | 256 | |

| Probe recognition | Automatic probe recognition | |

| Pulser/Receiver | Aperture | 32 elements* |

| Number of elements | 128 elements* |

| Pulser | PA Channels | UT Channels |

| Voltage | 40 V, 80 V, and 115 V | 95 V, 175 V, and 340 V |

| Pulse width | Adjustable from 30 ns to 500 ns, resolution of 2.5 ns | Adjustable from 30 ns to 1,000 ns; resolution of 2.5 ns |

| Pulse shape | Negative square pulse | Negative square pulse |

| Output impedance (32:128PR model) | 35 Ω in pulse-echo mode 30 Ω in pitch-catch mode |

< 30 Ω |

| Output impedance (all other models) | 25 Ω | < 30 Ω |

| Receiver | PA Channels | UT Channels |

| Gain | 0 dB to 80 dB, maximum input signal 550 mVp-p (full-screen height) | 0 dB to 120 dB maximum input signal 34.5 Vp-p (full-screen height) |

| Input impedance (32:128PR model) | 50 Ω in pulse-echo mode 90 Ω in pitch-catch mode |

60 Ω in pulse-echo mode 50 Ω in pitch-catch mode |

| Input impedance (all other models) | 65 Ω | 60 Ω in pulse-echo mode 50 Ω in pitch-catch mode |

| System bandwidth | 0.6 MHz to 18 MHz (-3 dB) | 0.25 MHz to 28 MHz (-3 dB) |

| Beamforming | Scan type | Sectorial and linear |

| Group quantity | Up to 8 | |

| Data Acquisition | Effective digitizing frequency | Up to 100 MHz |

| Maximum pulsing rate | Up to 10 kHz (C-scan) |

| Data Processing | PA Channels | UT Channels |

| Number of data points | Up to 8,192 | |

| Real-time averaging | 2, 4, 8, 16 | 2, 4, 8, 16, 32, 64 |

| Rectifier | RF, full wave, half wave +, half wave – | |

| Filtering | 3 low-pass, 3 band-pass, and 5 high-pass filters. | 3 low-pass, 6 band-pass, and 3 high-pass filters (8 low-pass filters when configured in TOFD) |

| Video filtering | Smoothing (adjusted to probe frequency range) | |

| Data Visualization | A-scan refresh rate | Real time: 60 Hz |

| Data Synchronization | On internal clock | 1 Hz to 10 kHz |

| On encoder | On 2 axes: from 1 to 65,536 steps | |

| Programmable Time-Corrected Gain (TCG) | Number of points | 32: One TCG curve per focal law |

| Alarms | Number of alarms | 3 |

| Conditions | Any logical combination of gates | |

| Analog outputs | 2 |

* Aperture and number of elements vary with each model. Current shipping models feature 16:64, 16:128, 32:128 configurations.