The Olympus 27MG is an affordable line of ultrasonic thickness gauges designed to take precise measurements from one side on metal pipes, tanks and other equipment that are corroded or corroded from the side. in. The device weighs only 340 g and ergonomic design for easy one-handed operation. Despite its compact size, the 27MG has many innovative measuring features using the same technologies found on our more advanced thickness gauges. The 27MG is durable, rugged, battery-operated, and features a large, backlit LCD display with easy-to-read digits and an intuitive color-coded keypad that provides direct access to many key features.

Standard features include Automatic probe identification to ensure optimal transducer performance, Zero compensation automatically to improve measurement accuracy on high temperature surfaces, Sensitivity Adjustment for improved measurement on sound attenuating materials such as cast metal, Differential Measurement Mode, Hi-Low Alert setting and Min/Max record minimum or maximum thickness at 20 measurements measure every second.

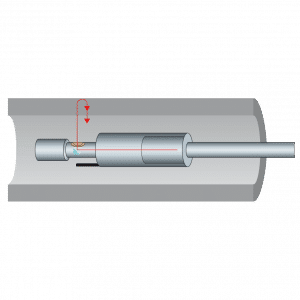

27MG is designed for inspectors and maintenance engineers who need to monitor the wall thickness of metal pipes, tanks, beams and structural supports that are susceptible to corrosion on internal surfaces. Ultrasonic thickness gauges provide a quick, cost-effective solution by using ultrasound that is transmitted to the material from the outside, without damaging the part to be measured.

Transducers/Transducers

The 27MG comes standard with the low-cost D7910 dual-element transducer that allows you to measure thickness for a wide variety of basic corrosion applications. For measurements on very thin or thick materials, or small diameter tubes, Olympus offers a full range of dual element transducer line or Specialized KIT for corrosion testing of extremely thin parts. The 27MG compatible Olympus probe features Automatic probe identification helps optimize transducer performance by automatically recalling the default V-path calibration.

Transducers with Automatic Probe Recognition

27MG is compatible with dual element transducers for every application.

| Transducer | Item Number | Freq. (MHz) | Connector | Tip Diameter mm (in.) | Range (Steel)* mm (in.) | Temp. Range** C (ºF) | Cable | Item Number |

| D7910 | U8454038 | 5.0 | 90° | 12.7 (0.500) |

1.00 to 254 (0.040 to 10.00) |

0 to 50 (32 to 122) |

Potted | ¯ |

| D790 | U8450002 | 5.0 | Straight | 11.00 (0.434) |

1.00 to 50000 (0.040 to 20,000) |

-20 to 500 (-5 to 932) |

Potted | ¯ |

| D790-SM | U8450009 | Straight | LCMD-316-5B† | U8800353 | ||||

| D790-RL | U8450007 | 90° | LCLD-316-5G† | U8800330 | ||||

| D790-SL | U8450008 | Straight | LCLD-316-5H | U8800331 | ||||

| D791 | U8450010 | 5.0 | 90° | 11.00 (0.434) |

1.00 to 50000 (0.040 to 20,000) |

-20 to 500 (-5 to 932) |

Potted | ¯ |

| D791-RM | U8450011 | 5.0 | 90° | 11.00 (0.434) |

1.00 to 50000 (0.040 to 20,000) |

-20 to 400 (-5 to 932) |

LCMD-316-5C | U8800345 |

| D792 | U8450012 | 10 | Straight | 7.20 (0.283) |

0.50 to 25.00 (0.020 to 1,000) |

0 to 50 (32 to 122) |

Potted | ¯ |

| D793 | U8450013 | 90° | Potted | ¯ | ||||

| D794 | U8450014 | 5.0 | Straight | 7.20 (0.283) |

0.75 to 50.0 (0.030 to 2,000) |

0 to 50 (32 to 122) |

Potted | ¯ |

| D797 | U8450016 | 2.0 | 90° | 22.9 (0.900) |

3.80 to 635.00 (0.150 to 25,000) |

-20 to 400 (-5 to 752) |

Potted | ¯ |

| D797-SM | U8450017 | Straight | LCMD-316-5D | U8800355 | ||||

| D7226 | U8454013 | 7.5 | 90° | 8.90 (0.350) |

0.71 to 50.00 (0.028 to 2,000) |

-20 to 150 (-5 to 300) |

Potted | ¯ |

| D798-LF | U8450019 | |||||||

| D798 | U8450018 | 7.5 | 90° | 7.20 (0.283) |

0.71 to 50.00 (0.028 to 2,000) |

-20 to 150 (-5 to 300) |

Potted | ¯ |

| D798-SM | U8450020 | Straight | LCMD-316-5J | U8800357 | ||||

| D799 | U8450021 | 5.0 | 90° | 11.00 (0.434) |

1.00 to 50000 (0.040 to 20,000) |

-20 to 150 (-5 to 300) |

Potted | ¯ |

| MTD705 | U8620225 | 5.0 | 90° | 5.10 (0.200) |

1.00 to 19.00 (0.040 to 0.750) |

0 to 50 (32 to 122) |

LCPD-78-5 | U8800332 |

*Depending on material, probe, surface condition, temperature the measuring range may vary.

**Maximum temperature based on intermittent exposure conditions.

†Cable with stainless steel sheath for added durability is reported separately.

Specifications

| Measurements | Dual element transducer measurement mode | Time interval from a precision delay after the excitation pulse to the first echo |

| Thickness range | 0.50 mm to 635 mm (0.020 in. to 25.0 in.) depends on material, transducer, surface conditions, temperature | |

| Material velocity range | 0.508 mm/μs to 18.699 mm/μs (0.020 in./μs to 0.7362 in./μs) | |

| Resolution (selectable) | Low: 0.1 mm (0.01 in.) Standard: 0.01 mm (0.001 in.) |

|

| Transducer frequency range | 2.25 MHz to 10 MHz (–3 dB) | |

| General | Operating temperature range | -10 °C to 50 °C (14 °F to 122 °F) |

| Keypad | Sealed, color-coded keypad with tactile and audible feedback | |

| Case | Impact-resistant and water-resistant, gasketed case with sealed connectors. Designed for IP65. | |

| Dimensions (W x H x D) | 84.0 mm x 152.4 mm x 39.6 mm (3.31 in. x 6.0 in. x 1.56 in.) | |

| Weight | 340 g (12 oz) | |

| Power Supply | 3 AA alkaline batteries | |

| Battery life operating time | 150 h of typical battery life, 30 h continuous use with backlight | |

| Explosive Atmosphere | Safe operation as defined by Class I, Division 2, Group D, as found in the National Fire Protection Association Code (NFPA 70), Article 500, and tested using MIL-STD-810F 511.4 Procedure I | |

| Standards | Designed for EN15317 | |

| Alarm mode | Programmable Hi/Low set points with audible and visual indicators | |

| display | Display Hold/Blank mode | Holds or blanks the display after measurements |

| Backlight | Electroluminescent backlight, Selectable as On or Auto On | |

| Receiver bandwidth | 1 MHz to 18 MHz (–3 dB) | |

| Metric/English mode | Metric or English units | |

| Display languages | English, French, German, Spanish, Italian, Portuguese, Russian, Polish, and Swedish |

Standard accessories

- 27MG digital ultrasonic thickness gage

- Dual element transducer

- AA alkaline batteries

- Test block and couplant

- Carrying case

- Wrist strap

- User's manual on CD

- Getting started Guide

- Measurement features: Min./Max. mode, Differential mode, Gain Adjust Freeze mode, Automatic Probe Recognition, Zero Compensation

Accessories are subject to change without notice. Please contact VISCO for more details.

Optional accessories

- 2214E (U8880014): 5-step test block, English units

- 2214M (U8880016): 5-step test block, metric units

- 27MG/RPC (U8780343): Protective rubber boot with Neck Strap and Gage Stand

When using the product for high-temperature applications or when testing on curved surfaces, additional accessories such as remote probe holder, curved surface adapter and contactors can be consulted. high temperature.